Automatic glaze spraying controlling method and controlling device for simulating skilled worker operation

A technology of skilled workers and control methods, applied in the direction of program control manipulators, manufacturing tools, manipulators, etc., can solve the problems of high cost and difficult teaching operation, and achieve the goal of reducing labor costs, reducing the difficulty of teaching operation, and reducing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described below through specific embodiments.

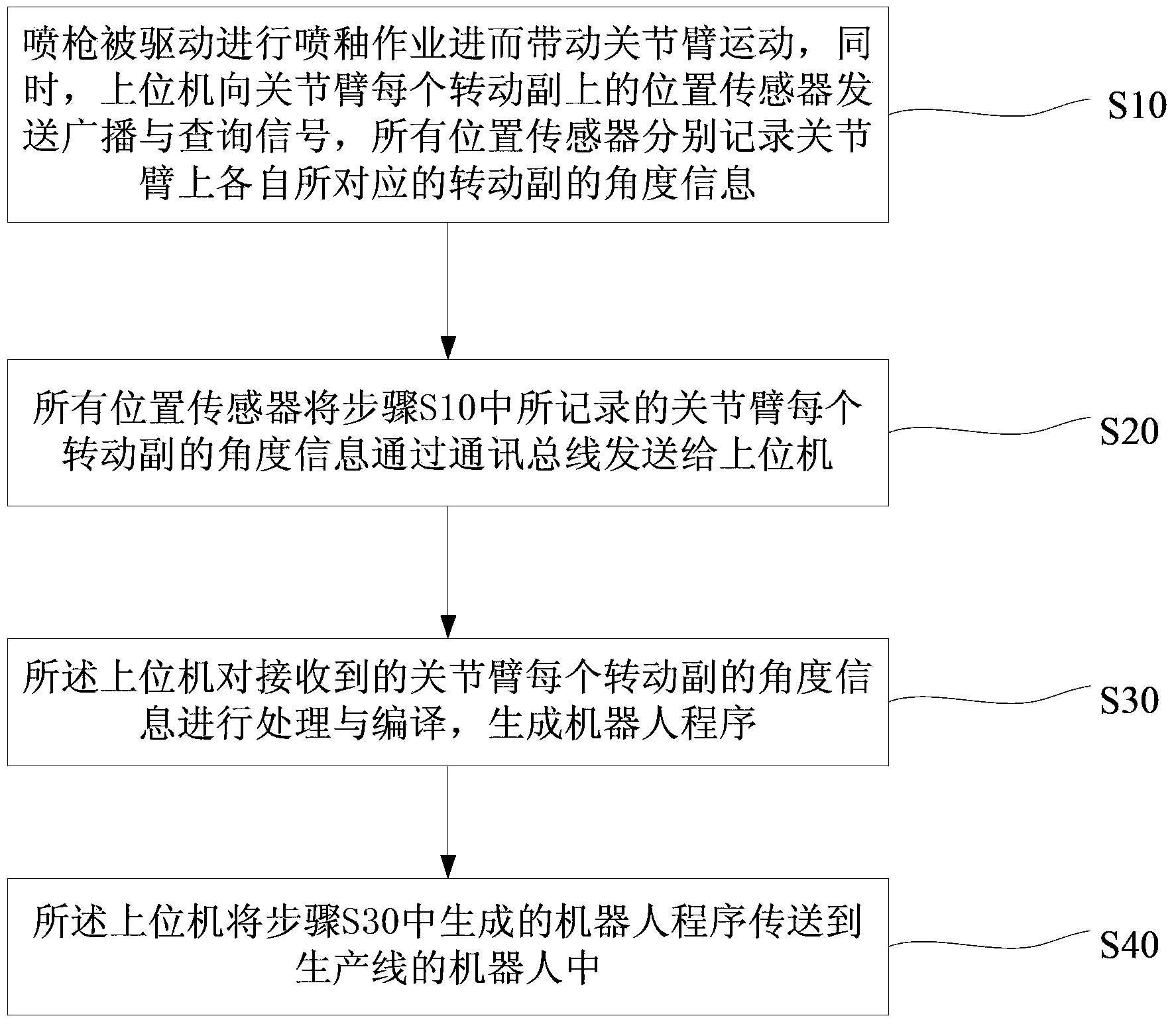

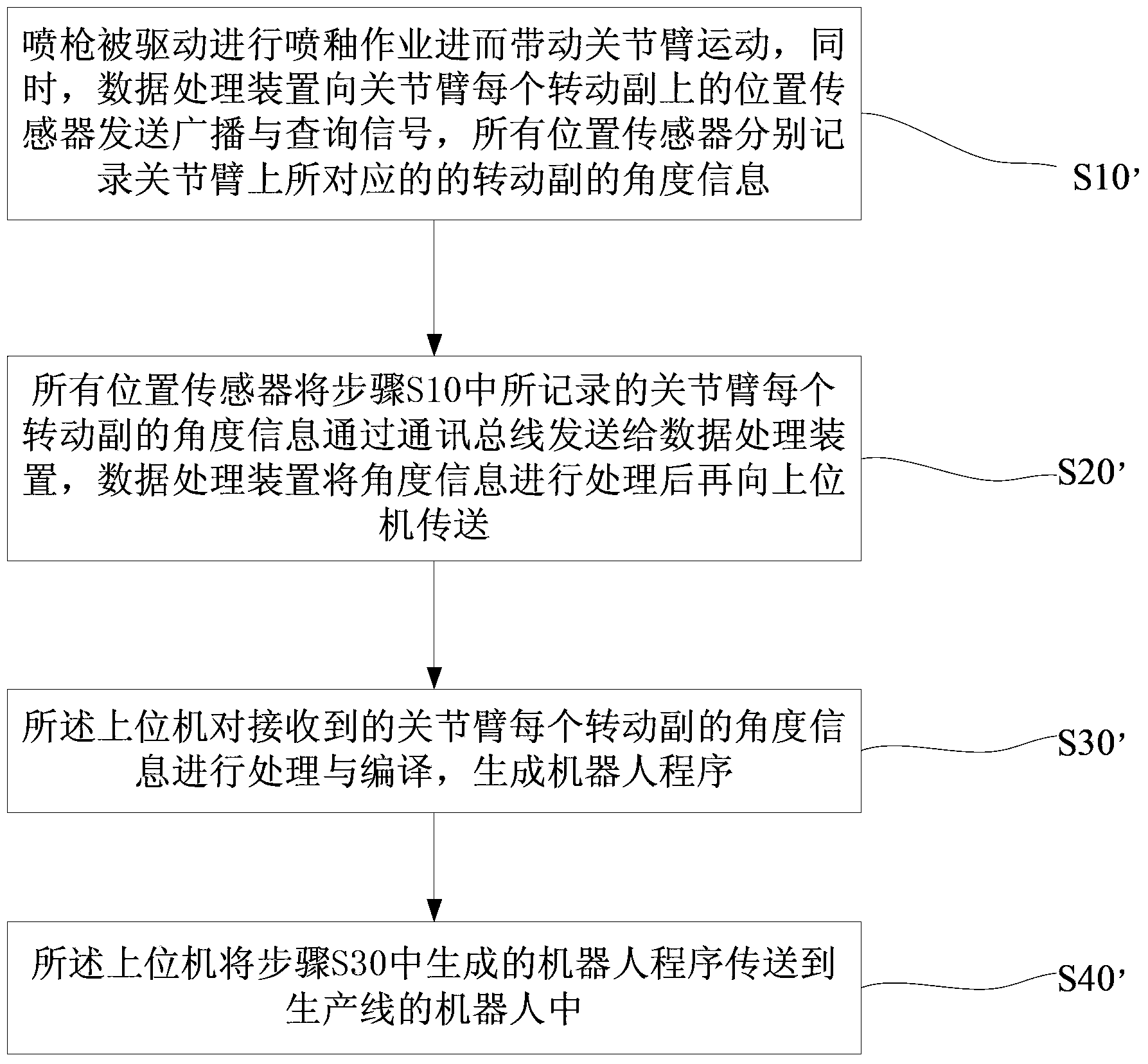

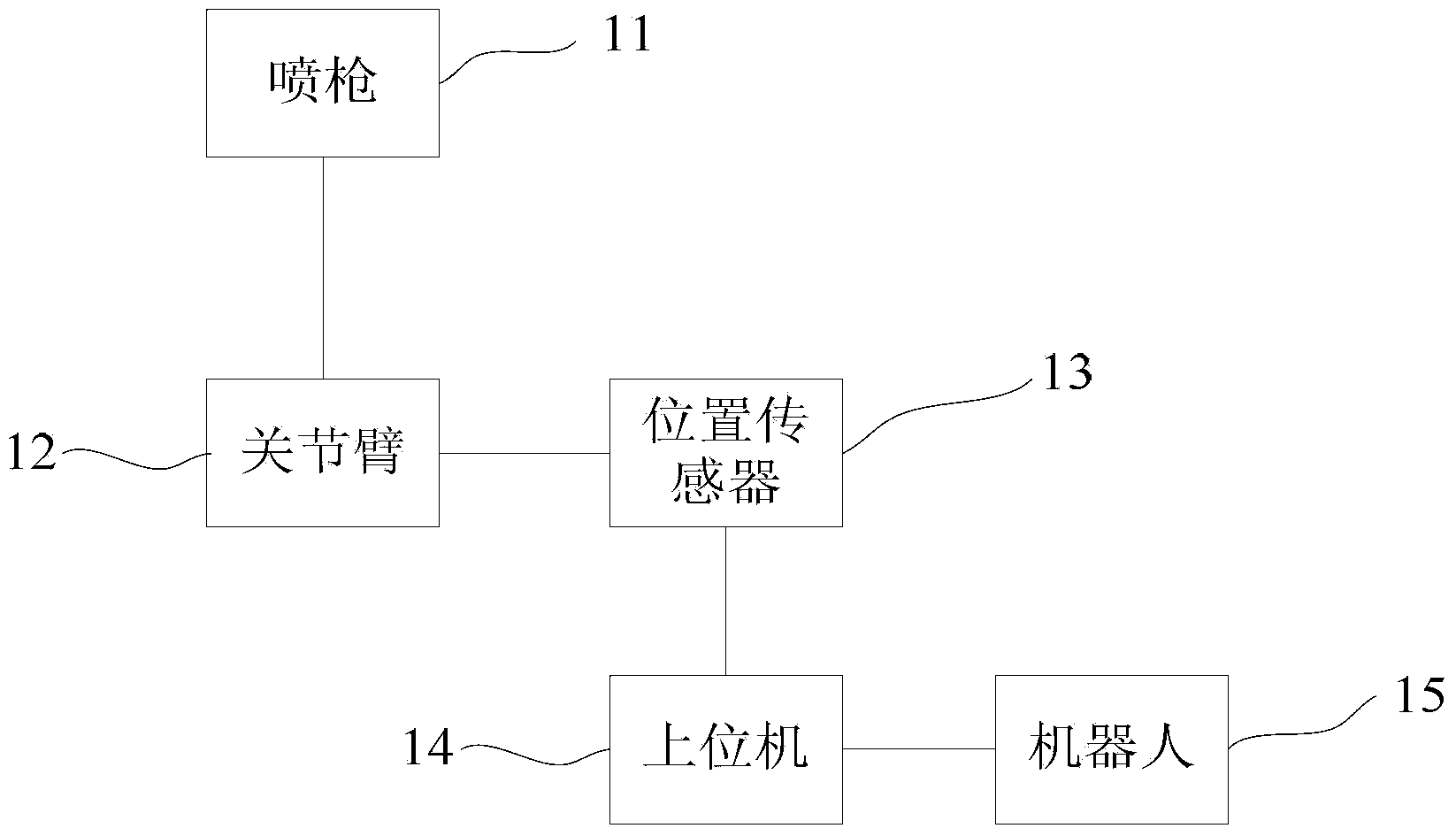

[0037] The automatic glazing control device for simulating the operation of skilled workers disclosed in the present invention is an articulated arm including a pose signal acquisition system whose size is consistent with that of a production line robot. The master control system broadcasts and inquires the position sensor through the communication bus. The articulated arm has no power and is flexible to guide. It is equipped with a position sensor and signal communication system, which can record its own position and posture signals to obtain the operation track. The articulated arm is used instead of the robot to teach on the production line, and the generated job trajectory signal (a data sequence) is transmitted to the host computer through the communication circuit. The operation trajectory is reproduced on the production line to realize a simple and eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com