Plastic pulverizer

A pulverizer and plastic technology, used in plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems of no classification treatment, inability to pulverize, damage to the pulverizing mechanism, etc., to achieve effective grinding and pulverizing effect, improve service life, Good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

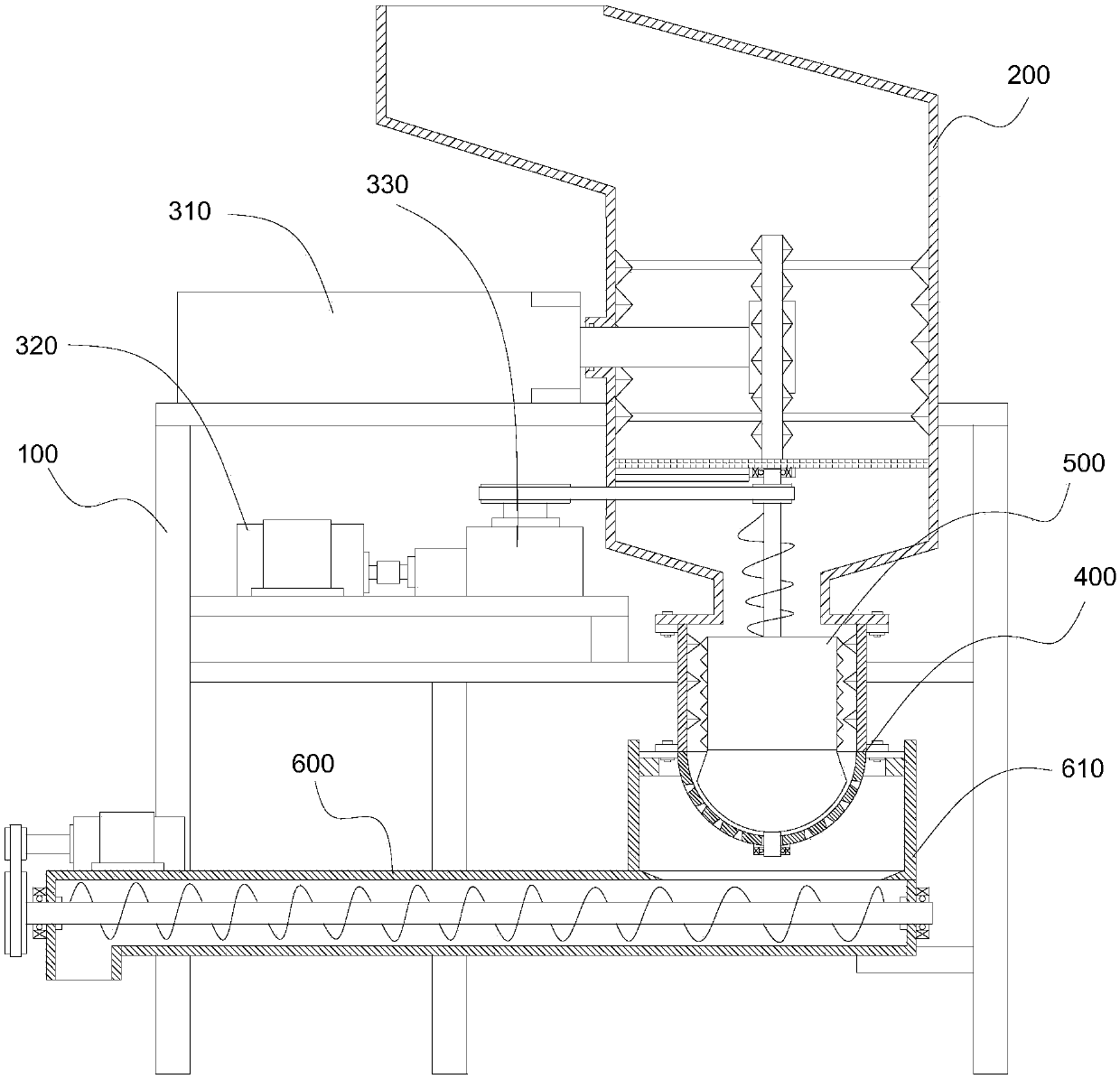

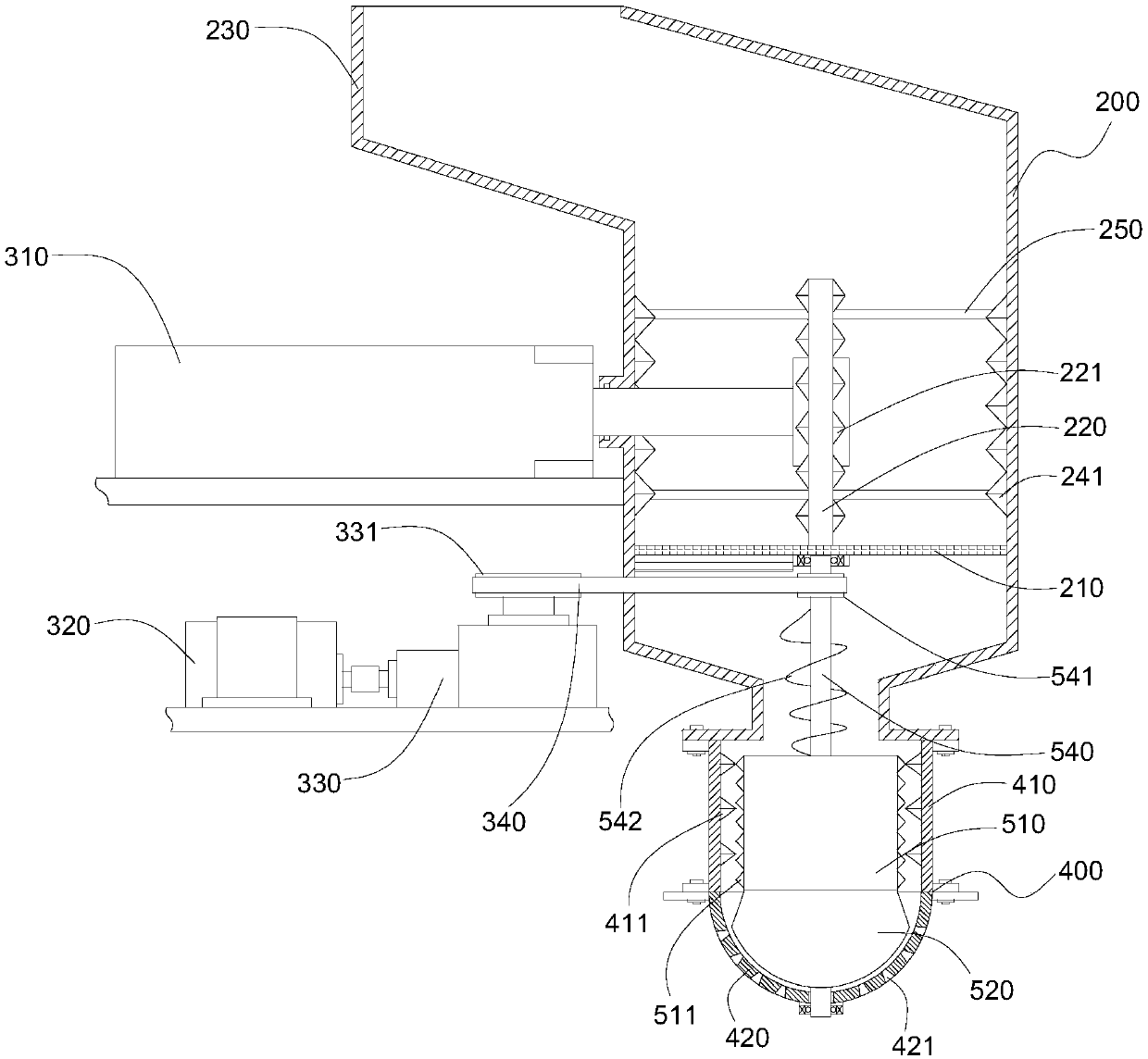

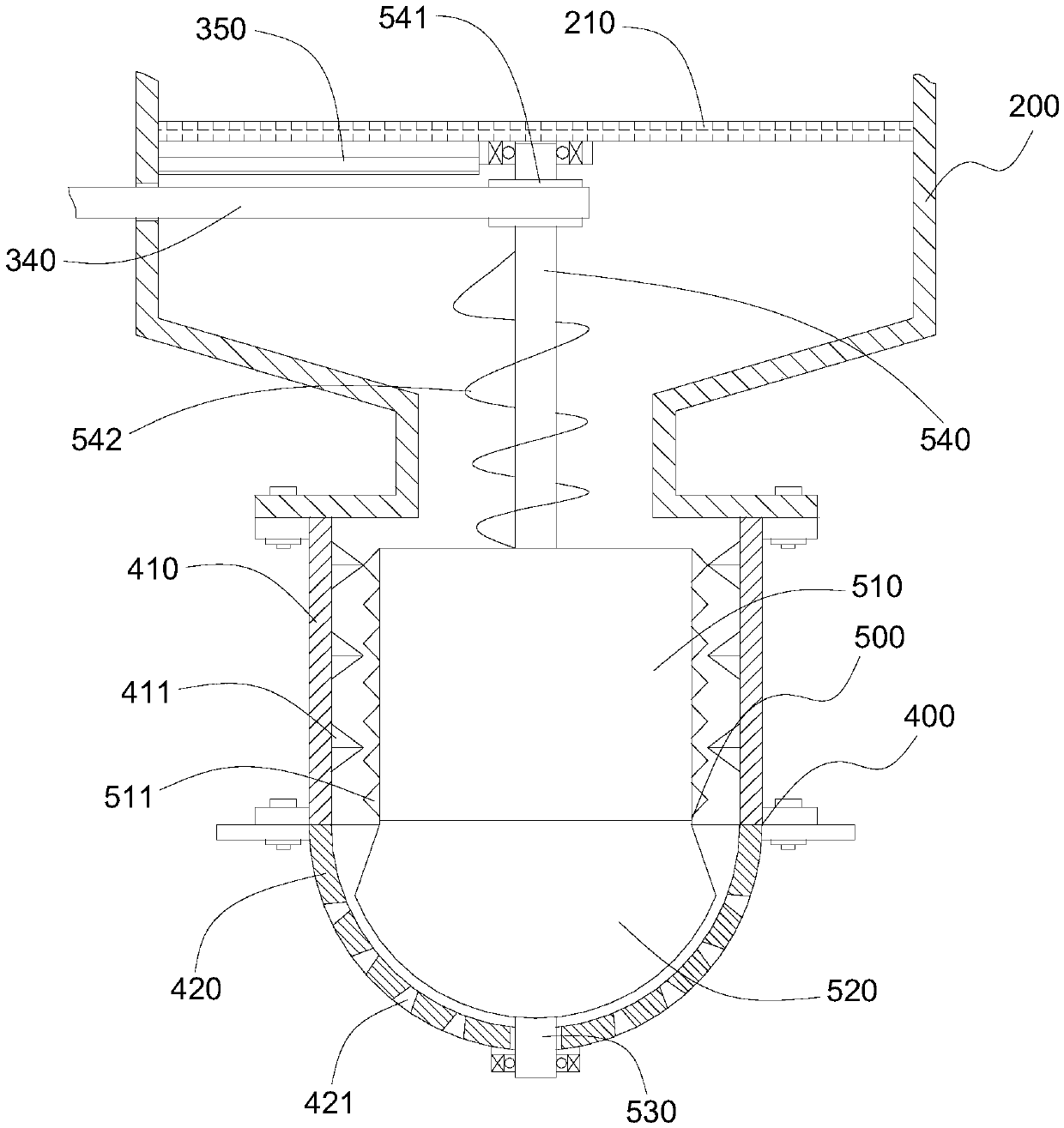

[0027] Such as figure 1 , figure 2 As shown, a plastic pulverizer is disclosed in a specific embodiment of the present invention, including a frame 100 and a squeeze box 200 fixed on the frame 100, and a horizontally placed box is fixed in the squeeze box 200. grid plate 210, the grid plate 210 is adapted to the shape of the inner wall of the extrusion box 100, and the surrounding is fixedly connected with the inner wall of the extrusion box 200, and the top surface of the grid plate 210 is slidably provided with Pressing plate 220, the pressing plate 220 is arranged vertically, a hydraulic cylinder 310 is provided on one side of the squeeze box 200, the hydraulic cylinder 310 is fixedly installed on the frame 100, and the piston rod of the hydraulic cylinder 310 penetrates The side walls and end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com