Pedal lever ratio adjustment control method and control system

A technology of adjusting control and lever ratio, applied in the direction of brakes, brake components, foot start devices, etc., can solve the problems of time-consuming and laborious, manual manual adjustment, waste of matching time, etc., to ensure driving safety, save matching time, overcome time consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

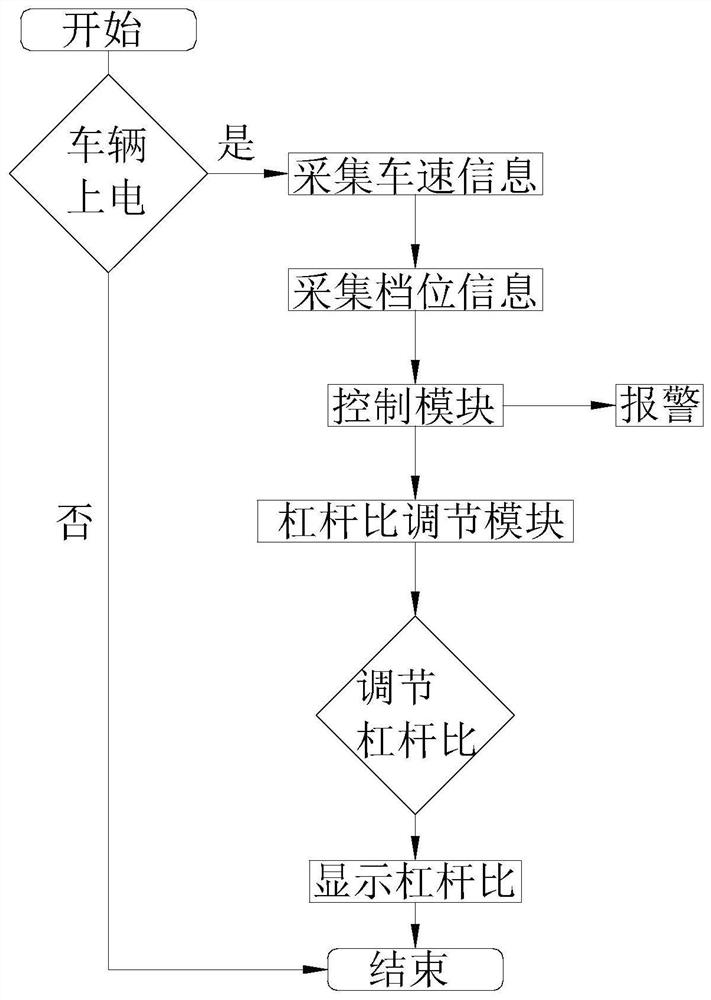

[0061] This embodiment relates to a pedal lever ratio adjustment control method, combining figure 1 As shown, it includes the following steps:

[0062] Step s1: power on the vehicle;

[0063] Step s2: start the leverage ratio adjustment function;

[0064] Step s3: Collect vehicle speed information and gear position information, and judge whether the vehicle speed information and gear position information meet the requirements; in this step, if the vehicle speed is equal to 0km / h, the vehicle speed information meets the requirements; if the gear position is in P or neutral, the gear position The information meets the requirements, and if the vehicle speed information and gear position information do not meet the requirements, an alarm will be issued.

[0065] Step s4: If the vehicle speed information and the gear position information meet the requirements, then drive the pivot shaft of the pedal arm to slide to change the position of the pivot shaft relative to the body, and ...

Embodiment 2

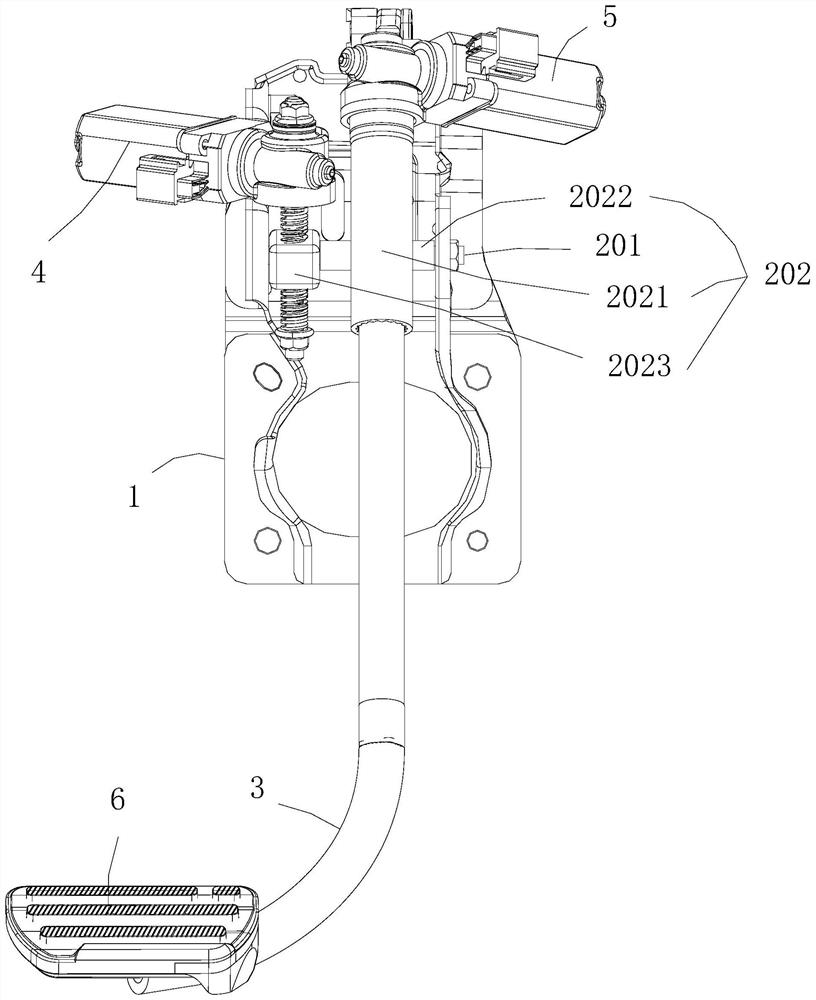

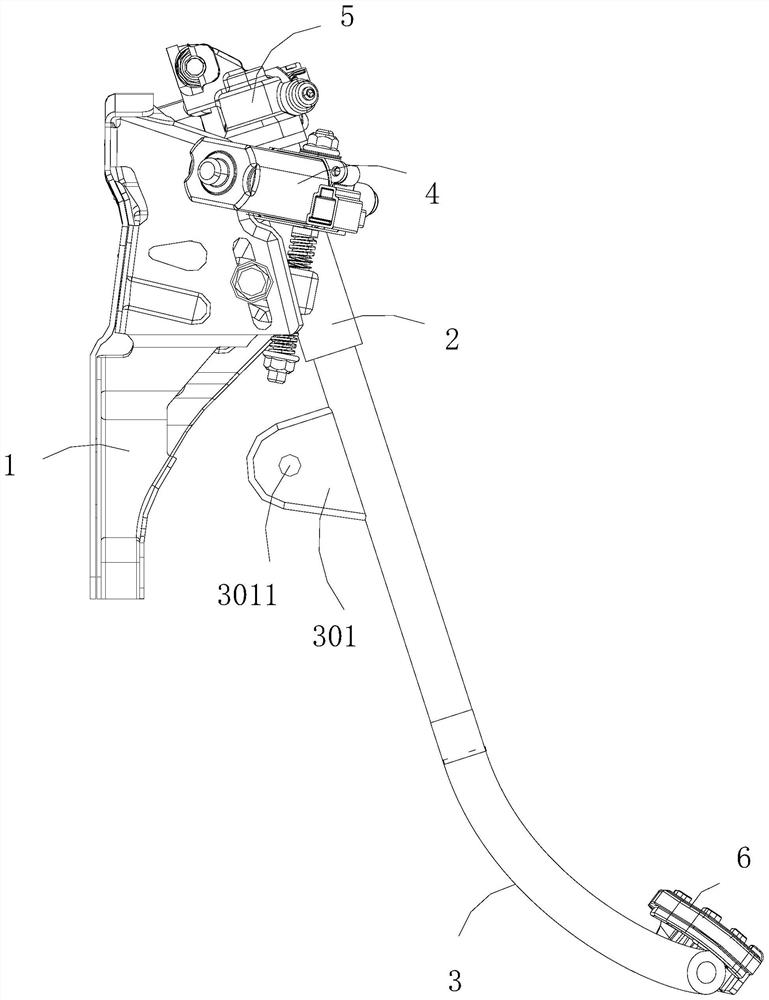

[0070] This embodiment relates to a pedal lever ratio adjustment control system for realizing the pedal leverage ratio adjustment function, mainly including a control module and a switch module connected to the control module, a data acquisition module and a leverage ratio adjustment module, wherein the switch module Used to start the control module, the data acquisition module is used to collect vehicle speed information and gear information, and the lever ratio adjustment module is used to drive the pivot shaft of the pedal arm to slide to change the position of the pivot shaft relative to the body and keep the pedal relative The position of the vehicle body remains unchanged, and the lever ratio of the pedal is adjusted.

[0071] In this embodiment, the switch module can be a structure in the prior art, which is used to input the driver's instruction information, so that the control module starts the lever ratio adjustment function; the control module can be a controller or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com