Adaptive label merging device for labeling machine

An adaptive, labeling machine technology, applied in labeling, labeling, packaging, etc., can solve problems such as cumbersome process, affecting labeling quality, film breakage, etc., achieves the effect of wide application range, improving work efficiency and labeling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

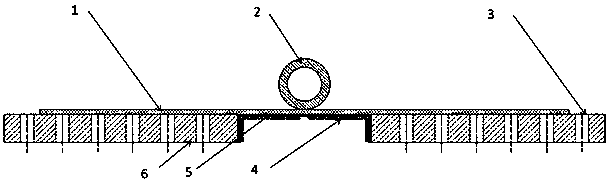

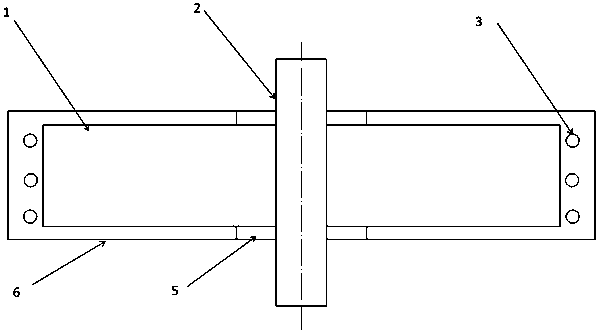

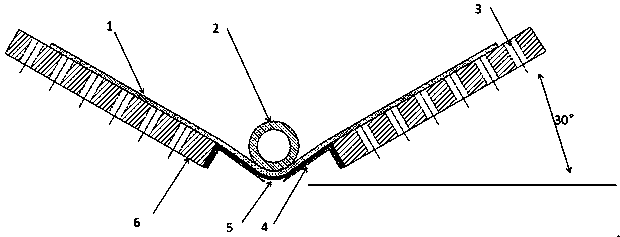

[0019] Such as figure 1 , figure 2 As shown, a labeling machine self-adaptive labeling device of the present invention is used in a double-folding labeling machine, and two standard-conforming suction plates 6 are arranged symmetrically on both sides of the folding axis, and the standard-conforming suction plate 6 is provided with A plurality of air holes 3, two standard-compliant suction plates 6 are flexibly connected through the wrapping leather 5, the wrapping leather 5 is in an inverted U shape, and two L-shaped elastic pressure strips 4 are symmetrically fixed on both sides of the inner wall of the wrapping leather 5 along the folding axis, The long side of the L-shaped elastic bead 4 is a pressing end, which is used to firmly attach the wrapped leather 5 and the label 1 thereon to the circumference of the labeling object 2 during the labeling process. A single standard suction plate 6 has 18 air holes 3 arranged in a 3×6 array. The short side of the L-shaped elastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com