Insulating flame-retardant bulk molding compound and preparation method thereof

A bulk molding compound, flame-retardant technology, applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc., can solve the problems of high-end automobiles and home appliance parts relying on imports and need to be improved, and achieve good modification effects , Improve the effect of insulation and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The present invention also provides a method for preparing an insulating and flame-retardant bulk molding compound, comprising the following steps:

[0060] Step 1: Preparation of unsaturated polyester,

[0061] It is formed by prepolymerization of polyether polyol and isocyanate, and co-curing and crosslinking with chain extender, catalyst, uncured unsaturated polyester and initiator to form unsaturated polyester interpenetrating network;

[0062] The polyether polyol is polytetrahydrofuran diol; the isocyanate is toluene diisocyanate or diphenylmethane diisocyanate; the chain extender is 1,4-butanediol; the catalyst is dibutyltin dilaurate; the initiator is peroxide Dibenzoyl;

[0063] The prepared unsaturated polyester is one or a composite of m-phenylene unsaturated resin, o-phthalic unsaturated resin, epoxy resin and vinyl unsaturated resin.

[0064] Step 2: Prepare modified inorganic flame retardant filler,

[0065] Add organosilane coupling agent or titanate c...

Embodiment 1

[0078] Step 1: Preparation of Unsaturated Polyester

[0079] Prepolymerize polytetrahydrofuran diol with toluene diisocyanate, then co-cure with 1,4-butanediol, dibutyltin dilaurate, and uncured unsaturated polyester and dibenzoyl peroxide to form unsaturated Polyester interpenetrating network.

[0080] Step 2: Prepare modified inorganic flame retardant filler,

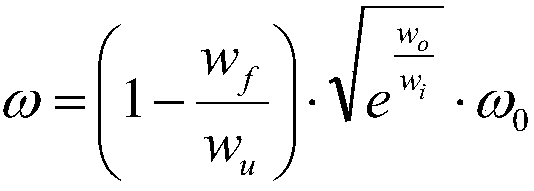

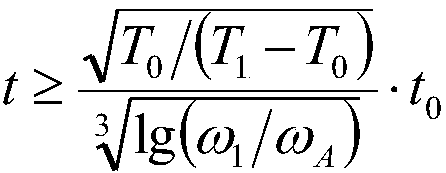

[0081] Add organosilane coupling agent or titanate coupling agent containing pyrophosphate group to the mixture of hollow glass microspheres, nano-aluminum hydroxide and nano-magnesium hydroxide, control the stirring speed to 26r / s, and the stirring temperature is 40°C, and the stirring time satisfies:

[0082]

[0083] Step 3: After stirring and mixing 30 parts of unsaturated polyester, 2 parts of thickener, 2 parts of auxiliary agent and 6 parts of internal mold release agent, slowly add 25 parts of modified inorganic flame retardant filler, 15 parts of silicone flame retardant 1 part and 20 parts of reinforci...

Embodiment 2

[0092] Step 1: Preparation of Unsaturated Polyester

[0093] Prepolymerize polytetrahydrofuran diol with toluene diisocyanate, then co-cure with 1,4-butanediol, dibutyltin dilaurate, and uncured unsaturated polyester and dibenzoyl peroxide to form unsaturated Polyester interpenetrating network.

[0094] Step 2: Prepare modified inorganic flame retardant filler,

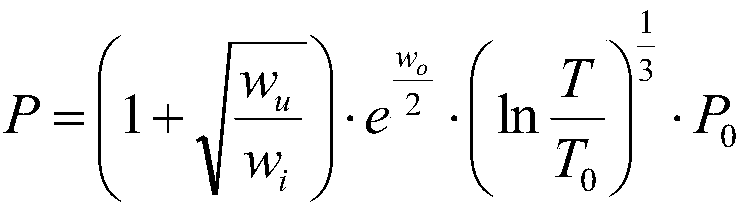

[0095] Add organosilane coupling agent or titanate coupling agent containing pyrophosphate group to the mixture of hollow glass microspheres, nano-aluminum hydroxide and nano-magnesium hydroxide, control the stirring speed to 30r / s, and the stirring temperature is 45°C, and the stirring time satisfies:

[0096]

[0097] Step 3: After stirring and mixing 50 parts of unsaturated polyester, 1 part of thickener, 1 part of auxiliary agent and 3 parts of internal release agent, slowly add 25 parts of modified inorganic flame retardant filler, 10 parts of silicone flame retardant 10 parts and 10 parts of reinforcing fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com