Mobile emergency solidification and stabilization equipment for household garbage incineration fly ash

A domestic waste incineration and mobile technology, which is applied in the direction of protective devices against harmful chemicals, can solve the problems of inability to handle fly ash, etc., and achieve the effect of flexible and fast walking and turning, convenient operation and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

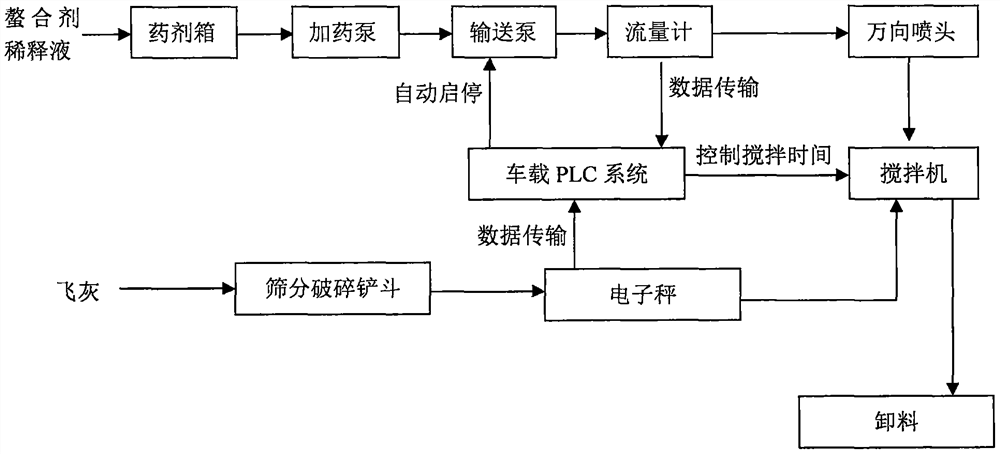

Method used

Image

Examples

Embodiment Construction

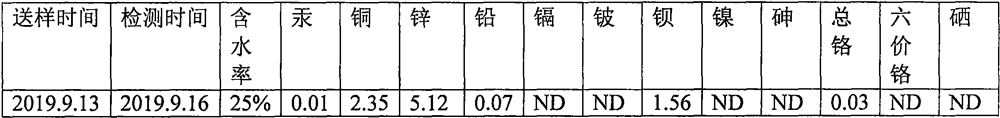

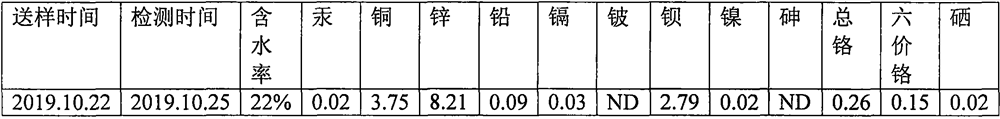

[0021] (1) The lumpy fly ash that has been stably solidified but unqualified is collected from the ground by the bucket into the bucket for screening and crushing, and then is weighed by the electronic weighing set at the boom of the loading bucket and then fed into the mixing system. The tank weighs 487kg. After the fly ash feeding is completed, the on-board PLC automatically calculates the theoretical amount of the chelating agent diluent added according to the feeding amount, the weight is about 163kg, and automatically turns on the chelating agent diluent electronic pump to start adding the chelating agent diluent to the stirring tank.

[0022] The fly ash and chelating agent are stirred for 1.5 minutes in the stirring tank. After the stirring is completed, lower the stirring tank to the low position, and at the same time move the stirring lever to the discharge position, and the material in the stirring tank will be pushed to the discharge port by the spiral stirring blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com