A kind of graphene rare earth scandium synergistically reinforced cast aluminum alloy and its application in automobile wheel hub

A technology for casting aluminum alloys and automobile wheels, which is applied in the field of casting aluminum alloys. It can solve the problems of low density of parts, poor material properties, and easy segregation, etc., achieve excellent electrical conductivity, improve comprehensive mechanical properties, and improve alloys. The effect of elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

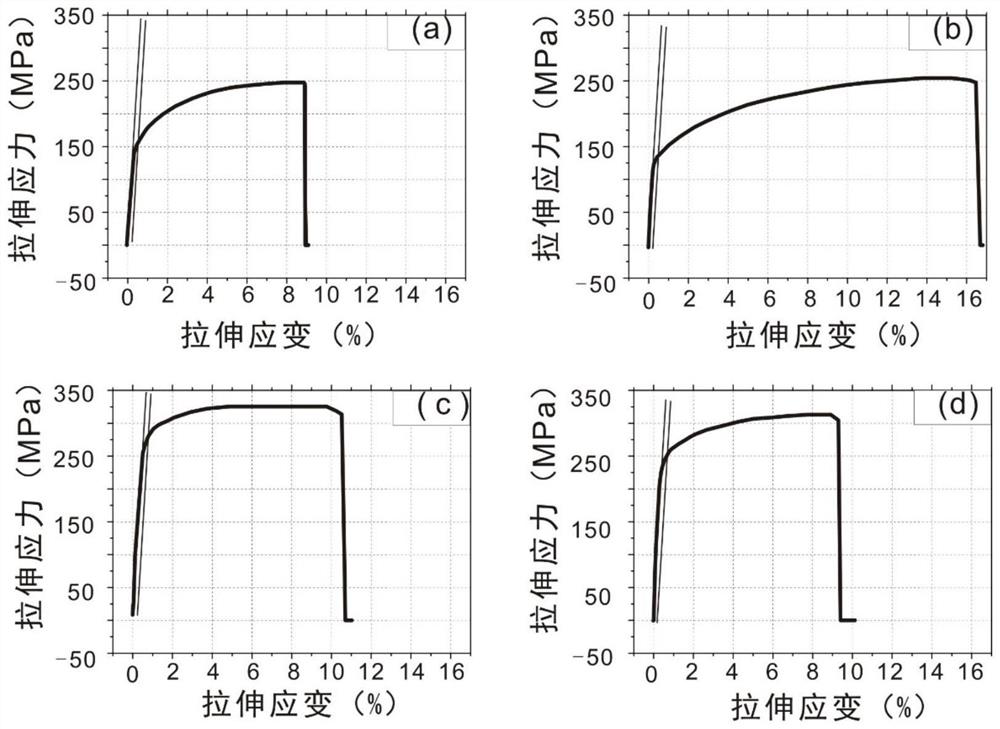

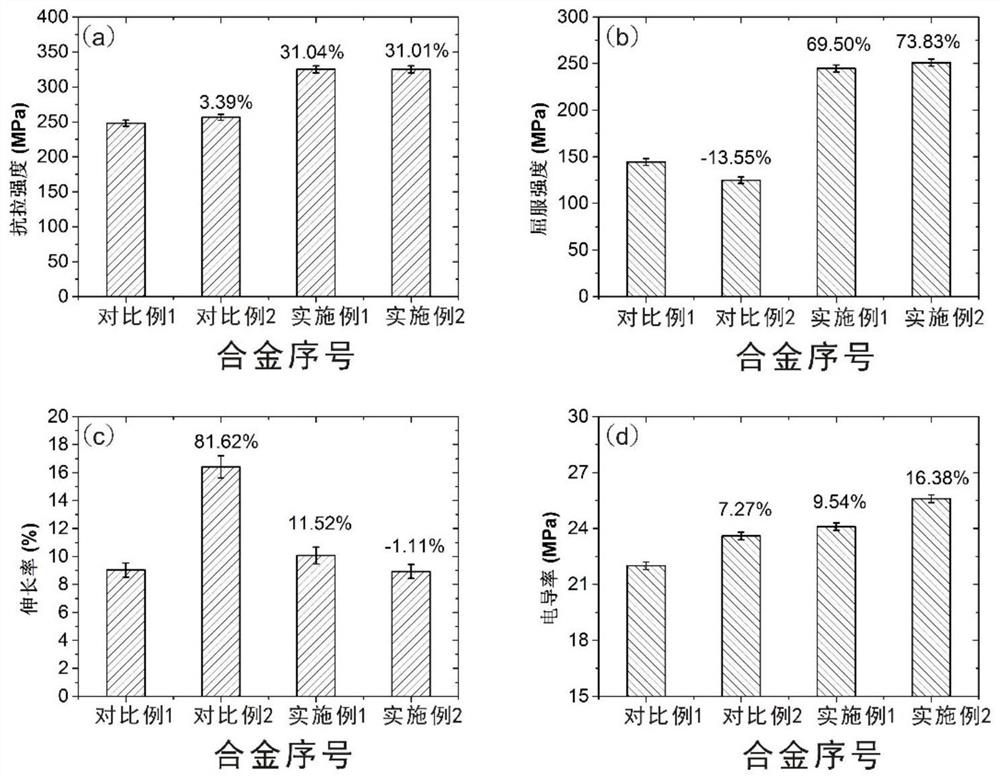

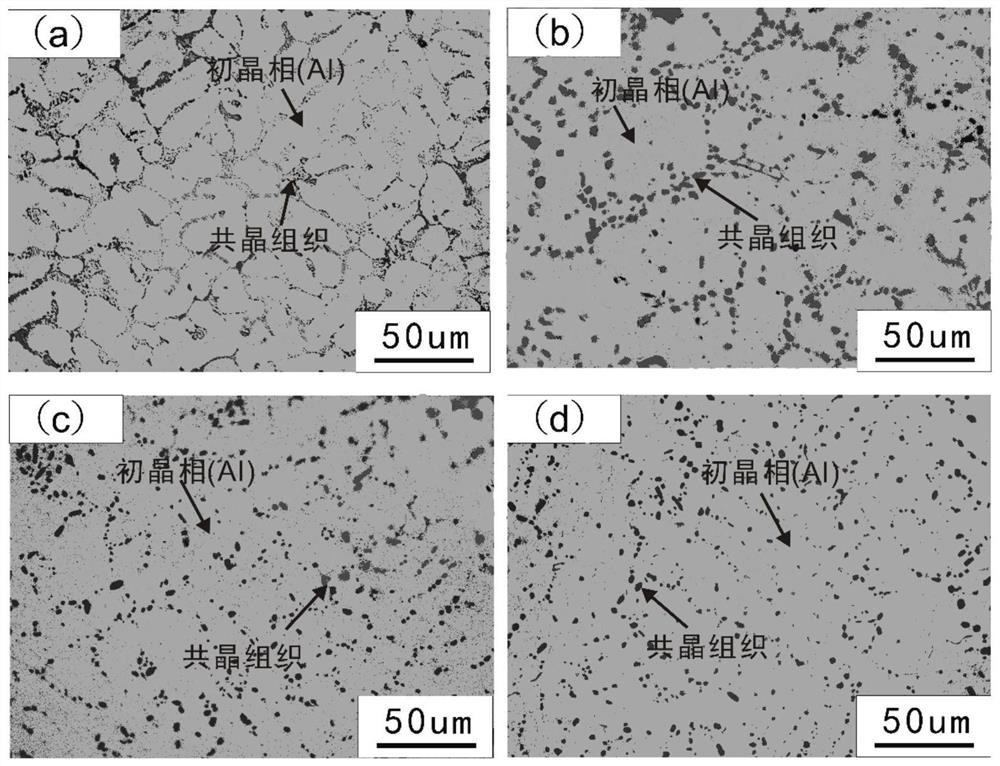

Embodiment 1

[0048] A graphene rare earth scandium synergistically reinforced cast aluminum alloy, the weight percentage of each raw material is: Sc 0.54wt.%, graphene 0.003wt.%, Si 6.90wt.%, Mg 0.40wt.%, Li 0.02wt.%, Be 0.02wt.%, B0.02wt.%, Na 0.02wt.%, P 0.02wt.%, Ti 0.03wt.%, V 0.03wt.%, Cr 0.02wt.%, Mn0.03wt.%, Fe 0.02 wt.%, Ni 0.03wt.%, Cu 0.02wt.%, Zn 0.02wt.%, Zr 0.03wt.%, Sn0.02wt.%, Pb 0.03wt.%, other unspecified other impurity elements: each ≤0.01wt.%, total ≤0.10wt.%, the balance is Al.

[0049] Its preparation method steps are as follows:

[0050] (1) Calculate and weigh raw materials according to the alloy composition, the total mass of raw materials is 75 grams, aluminum grains, silicon grains, magnesium grains, graphene powder, scandium grains, lithium grains, beryllium grains, boron grains, sodium grains, phosphorus grains, Titanium grains, vanadium grains, chromium grains, manganese grains, iron grains, nickel grains, copper grains, zinc grains, zirconium grains, tin gra...

Embodiment 2

[0056] A graphene rare earth scandium synergistically reinforced cast aluminum alloy, the weight percentage of each raw material is: Sc 0.54wt.%, graphene 0.003wt.%, Si 6.90wt.%, Mg 0.40wt.%, Li 0.02wt.%, Be 0.02wt.%, B0.02wt.%, Na 0.02wt.%, P 0.02wt.%, Ti 0.03wt.%, V 0.03wt.%, Cr 0.02wt.%, Mn0.03wt.%, Fe 0.02 wt.%, Ni 0.03wt.%, Cu 0.02wt.%, Zn 0.02wt.%, Zr 0.03wt.%, Sn0.02wt.%, Pb 0.03wt.%, other unspecified other impurity elements: each ≤0.01wt.%, total ≤0.10wt.%, the balance is Al.

[0057] Its preparation method steps are as follows:

[0058] (1) Calculate and weigh raw materials according to the alloy composition, the total mass of raw materials is 75 grams, aluminum grains, silicon grains, magnesium grains, graphene powder, scandium grains, lithium grains, beryllium grains, boron grains, sodium grains, phosphorus grains, Titanium grains, vanadium grains, chromium grains, manganese grains, iron grains, nickel grains, copper grains, zinc grains, zirconium grains, tin gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com