False twist texturing machine with improved yarn channel

A technology of false twist texturing machine and silk path, which is applied in the direction of textiles and papermaking, and can solve problems such as inflexible rotation, increased frictional resistance, and severe twist resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

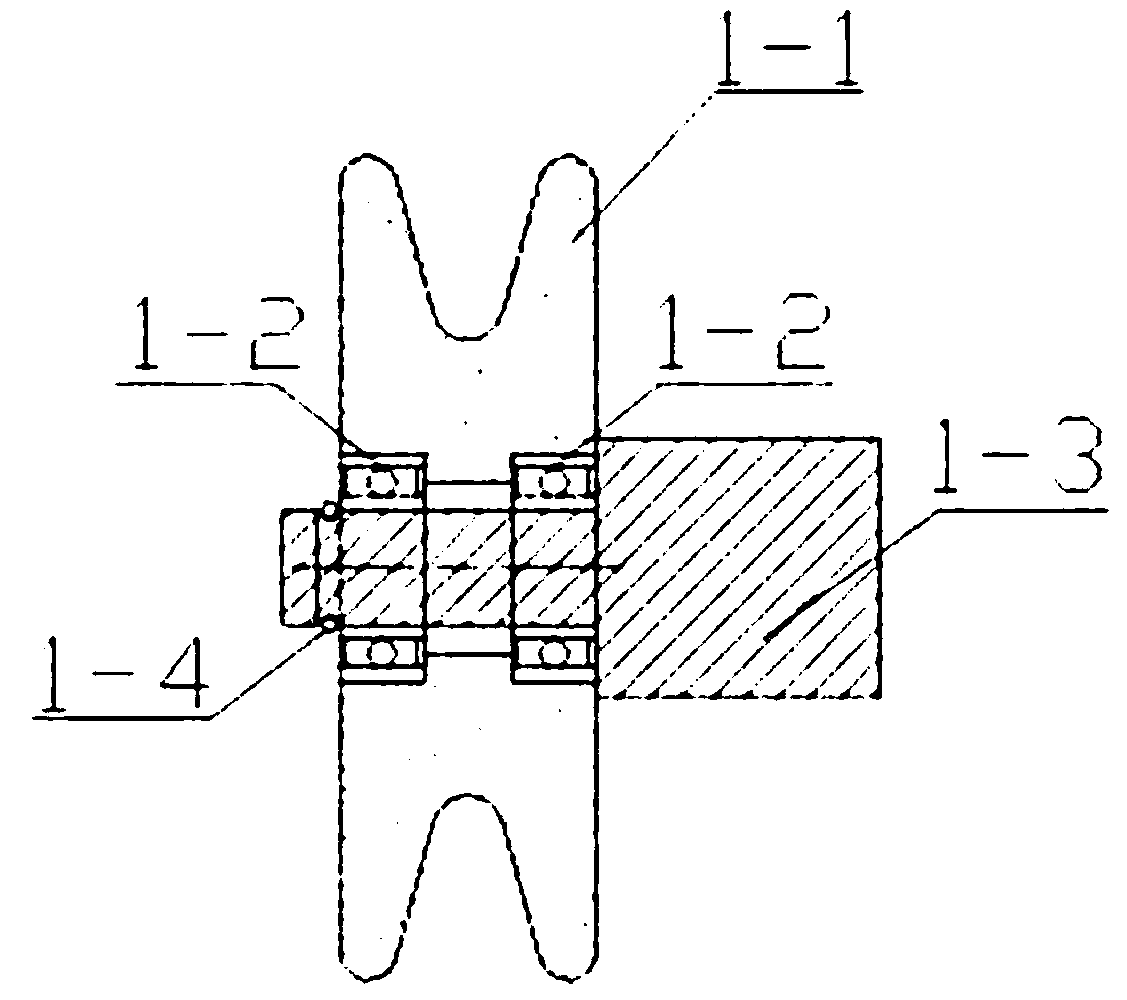

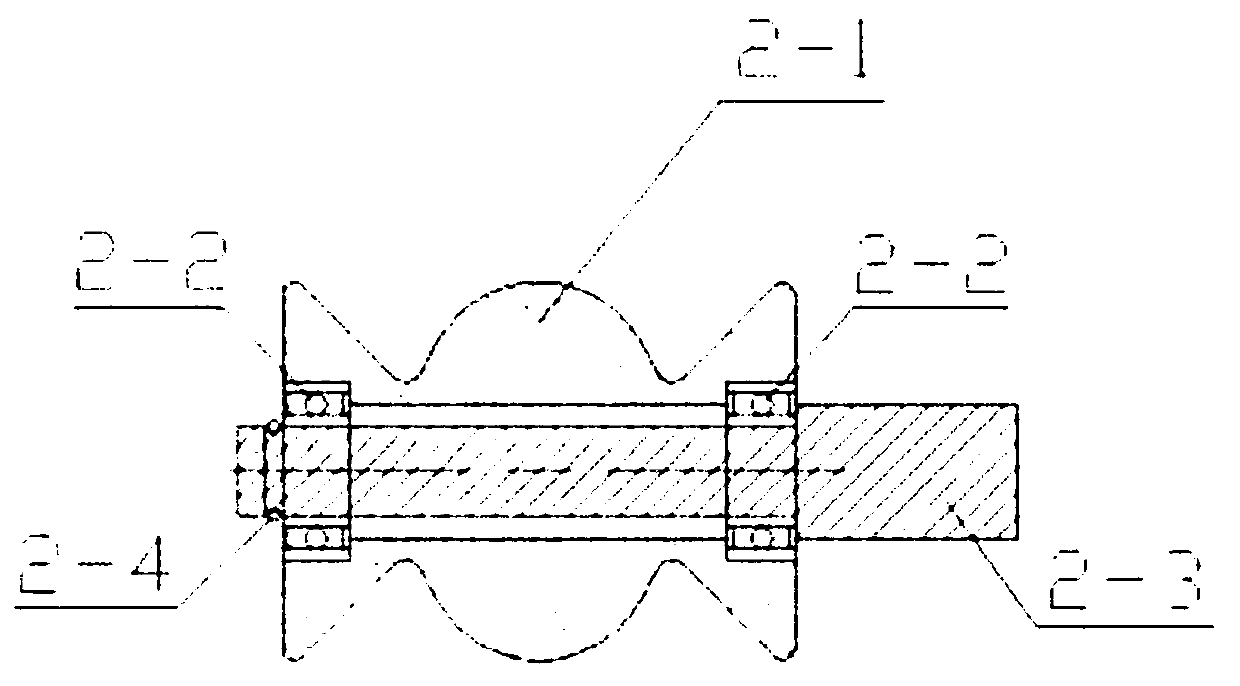

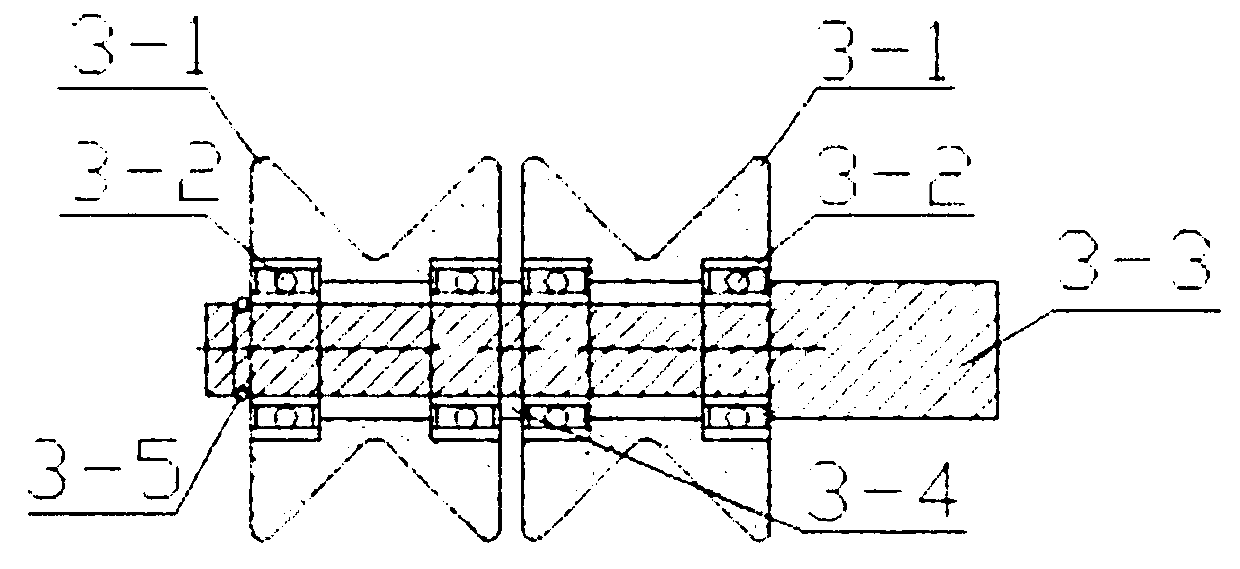

[0014] The present invention is a false twist texturing machine with improved thread path, which includes a flat porcelain wheel of the lifting screw rod, an inlet porcelain part of the upper heating box, an outlet porcelain part, and a guide wire porcelain part on the false twister. The improvement of the present invention lies in: Any one or more of the rod flat porcelain wheel, the inlet porcelain piece of the upper heating box, the outlet porcelain piece, and the upper guide wire porcelain piece of the false twister are installed on the respective central shafts through miniature bearings.

[0015] Specifically, the flat porcelain wheel of the ascending screw, the porcelain piece at the entrance of the upper heating box, the porcelain piece at the outlet, and the porcelain piece on the guide wire of the false twister can all be installed on their corresponding central shafts through miniature bearings, or can be partially mounted on the corresponding central shaft through mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com