Inerter-based particle damper

A particle damper and particle damping technology, which is applied to building components, building types, earthquake resistance, etc., can solve complex nonlinear characteristics, problems such as optimization and numerical simulation cannot be achieved, and achieve reduced nonlinear characteristics and good energy consumption The effect of shock absorption and enhancing the ability of energy dissipation and shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

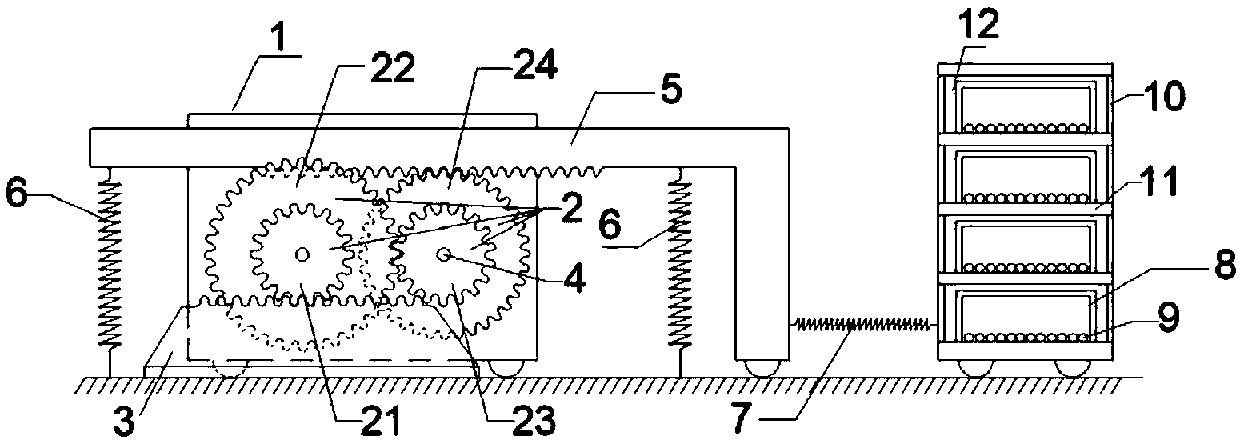

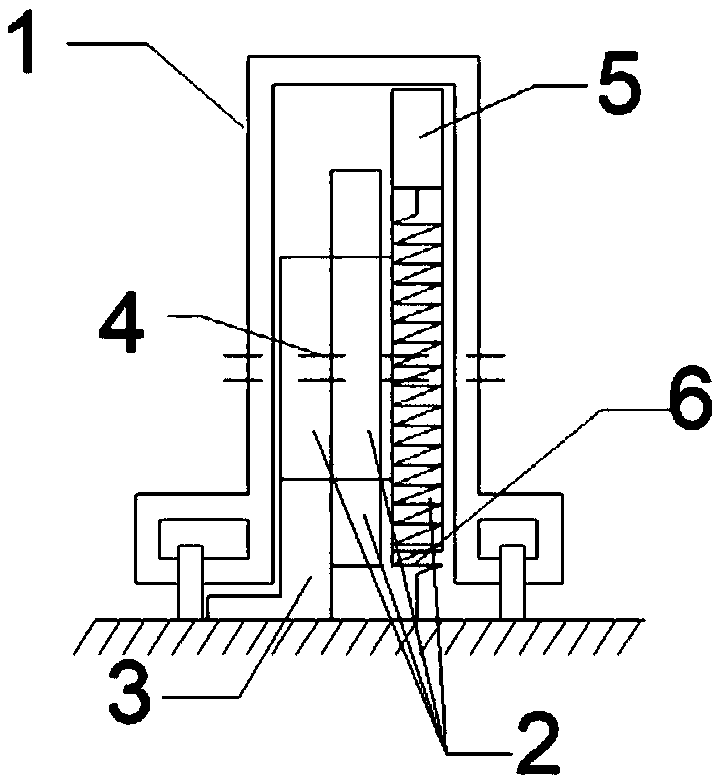

[0025] A particle damper using inertial capacity, which can be fixed on the top of the structure to be damped, and its structure is as follows figure 1 , figure 2 shown. In this embodiment 1, the maximum length and width of the outer box 1 are: 220×170mm, the thickness is 10mm, and it is hollow inside, the size of the bottom pulley is R15×10mm, and the inner diameters of the four gear sets 2 are 35mm, 75mm, 35mm and 65mm, the thickness is 20mm, the thickness of the fixed plate 3 is 20mm, the maximum height and maximum width are 62mm and 50mm, the size of the connecting rod 5 is 600×32×200×45, and the thickness is 20mm, and other dimensions can be obtained according to the proportion It is shown that the particle chamber 8 has a size of 255×150mm, the thickness of the rigid base plate 11 is 20mm, the diameter of the particle 9 is 7.5mm, the diameter of the cylinder 12 is 120mm, and the height is 45mm.

[0026] The outer box 1, the gear set 2, the hinge rod 4, the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com