Combined structure of impeller

A combined structure and impeller technology, which is applied in liquid fuel engines, mechanical equipment, buildings, etc., can solve the problems of relatively tight blade design and loud noise, and achieve good mute effect, reduce noise, and increase air suction volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

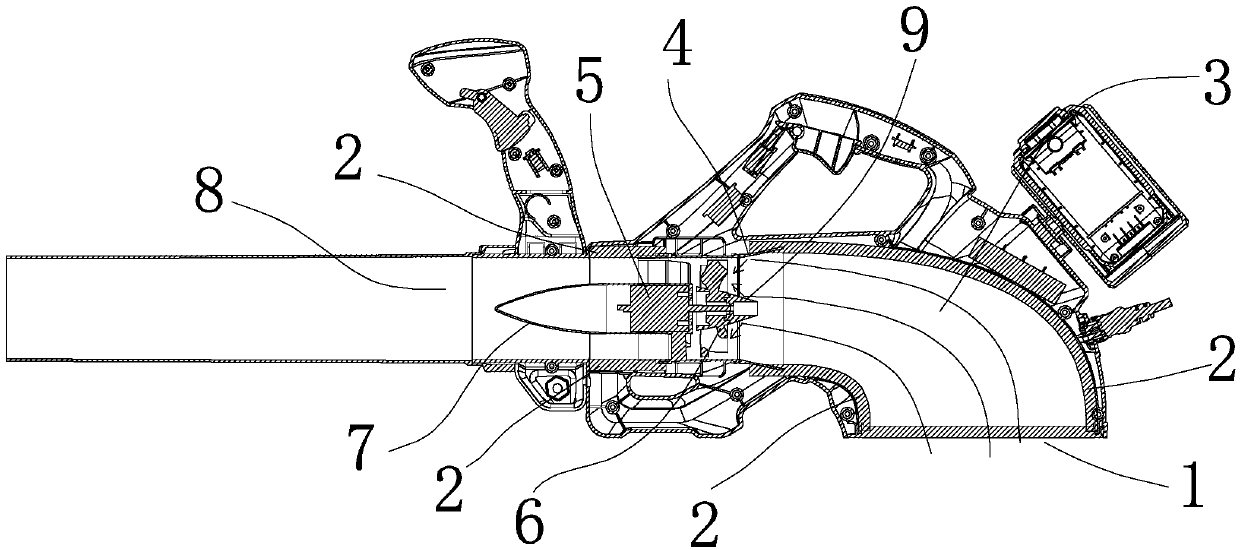

[0018] Figure 1-Figure 2 The inside of the middle blower includes the air channel cavity 3, the air inlet 1 and the air outlet 8, and the air inlet 1 is designed to open downward, so that the operator has the least impact when holding it. A sponge sheet 2 is arranged in the air duct cavity 3, and the sponge sheet 2 fills up the air duct cavity 3 to eliminate concave and convex areas in the air duct cavity 3, so that whistles cannot be produced. Since the sponge sheet 2 itself is porous, the sponge sheet 2 also has the function of sound absorption.

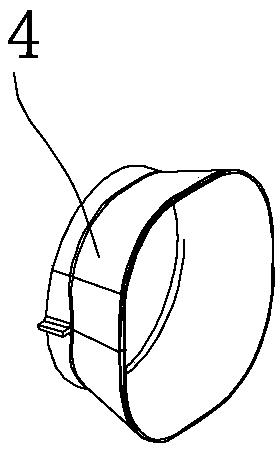

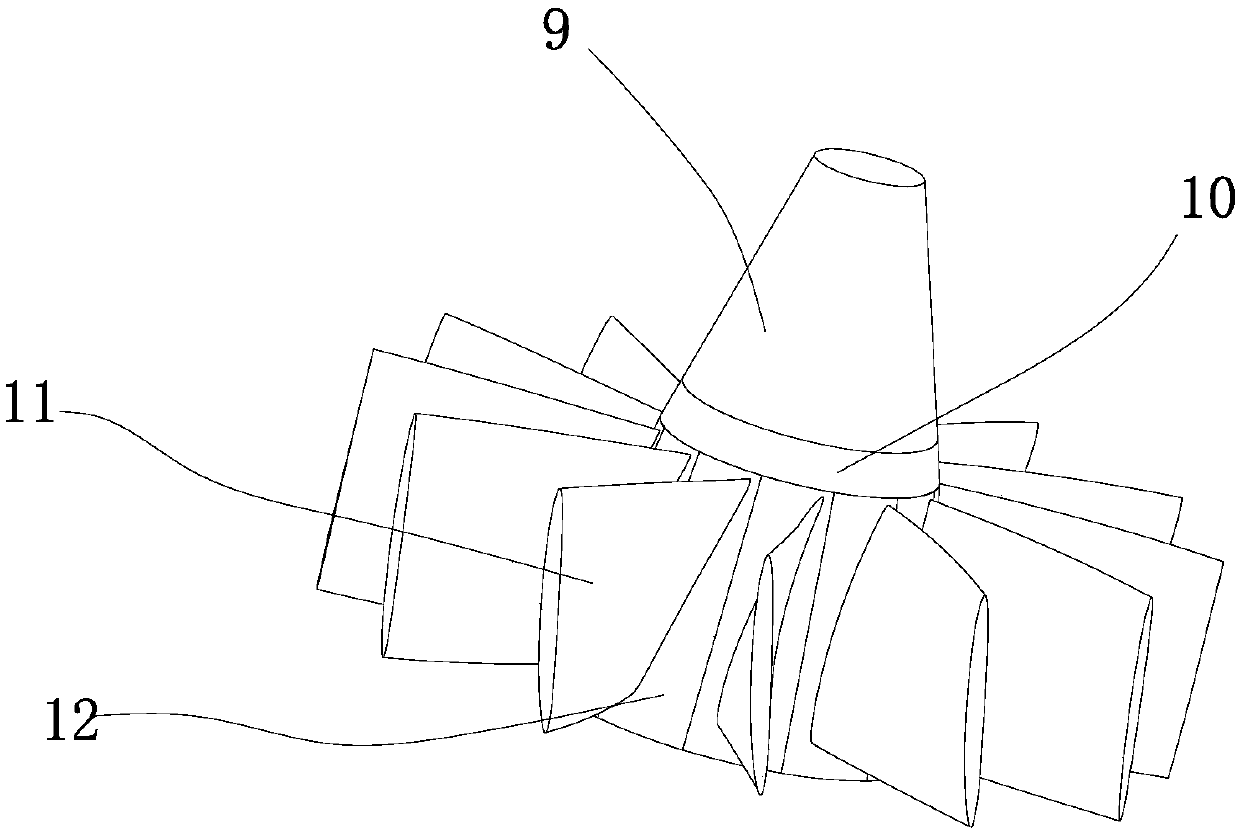

[0019] The impeller 6 of the present invention is horizontally blocked in the air channel chamber 3, and a motor 5 is provided to drive the impeller 6 to rotate. The front of the impeller 6 is provided with a shroud 4, the shroud 4 is trumpet-shaped, and the shroud 4 has a large mouth. Facing the air inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com