Method for online monitoring the operating state of environmental dedusting system

A technology of dust removal system and operation status, which is applied in the testing, measuring devices, instruments of machines/structural parts, etc., can solve problems such as environmental pollution, inconvenient management and maintenance, and mismatch of air volume of dust removal system, so as to ensure normal operation and improve dust removal. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

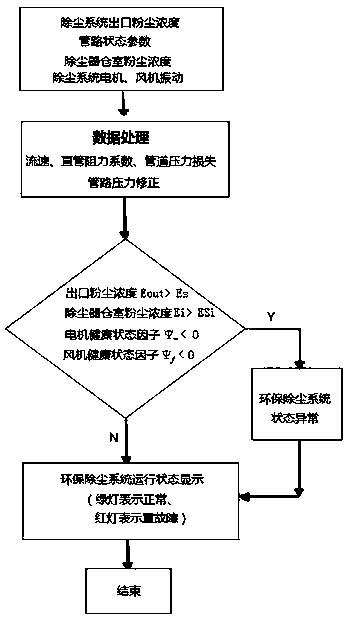

[0033] Example figure 1 As shown, the online monitoring method of the environmental protection dust removal system operating state of the present invention comprises the following steps:

[0034] Step 1. Install dust concentration monitors at the outlet of the environmental protection dust removal system and each dust collector chamber, and install vibration acceleration sensors on the bearing seats of each motor and fan rolling bearing, and simultaneously collect the pressure and flow parameters of the pipeline system;

[0035] Step 2. Collect the output signal E of the dust concentration monitor at the outlet of the environmental protection dust removal system out , set the emission concentration standard value E of the environmental protection dust removal system s ; When the outlet dust concentration E out >E s , the online monitoring system sends an alarm signal;

[0036] Step 3, according to the pressure parameter P of the pipeline system, the flow parameter Q, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com