Multi-steel-pipe water pressure test machine

A technology of hydraulic testing machine and steel pipe, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc. The effect of high pressure test efficiency and saving pressure test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

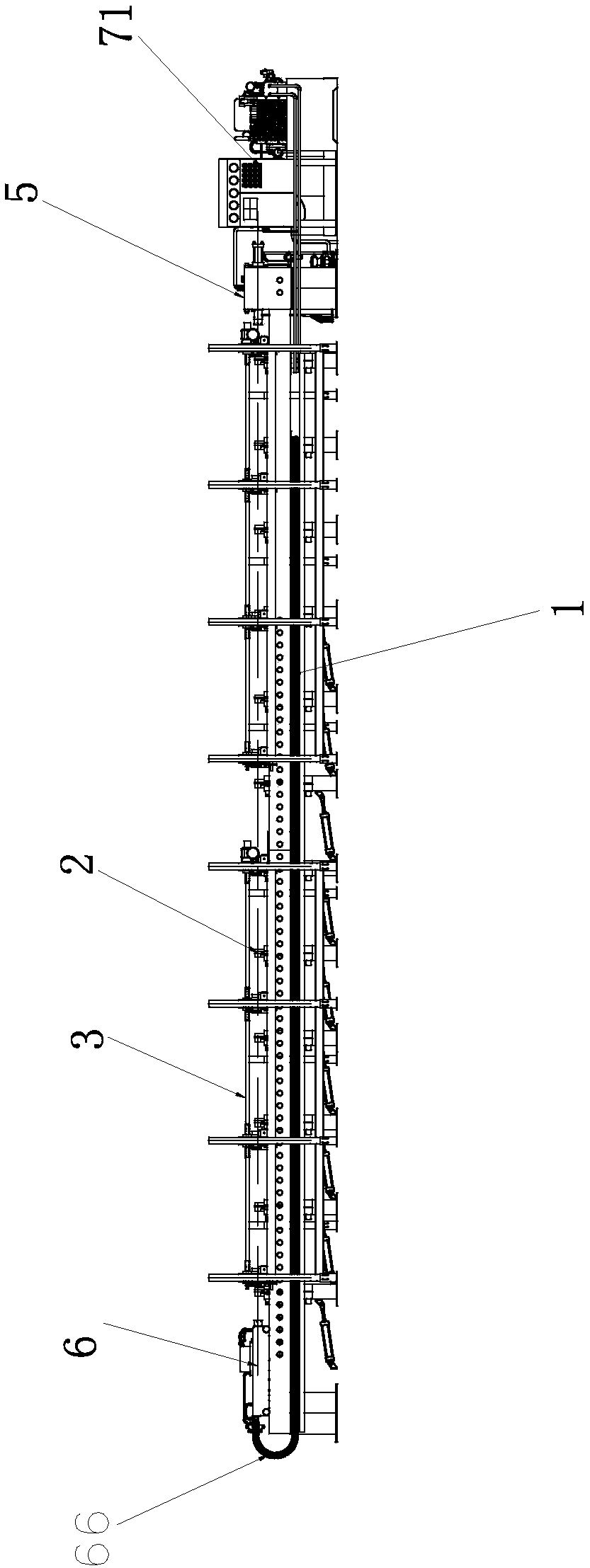

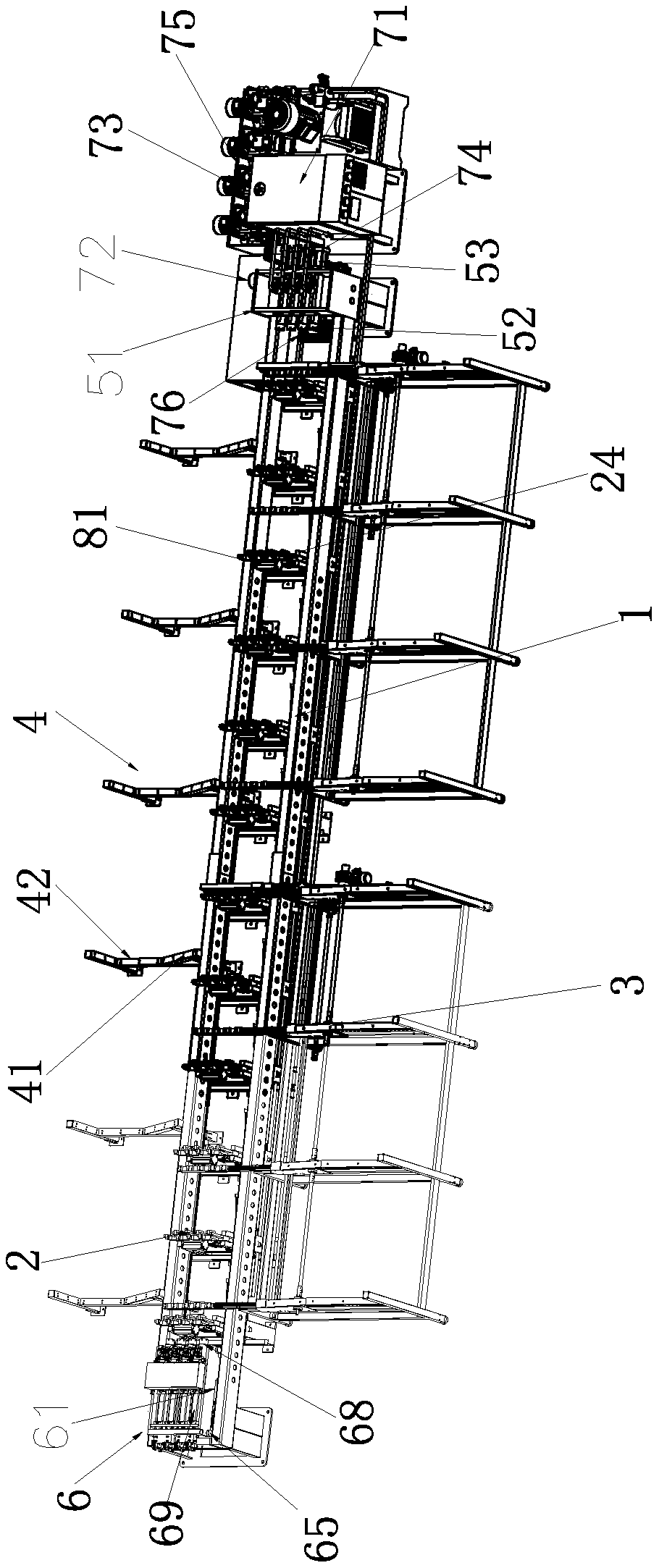

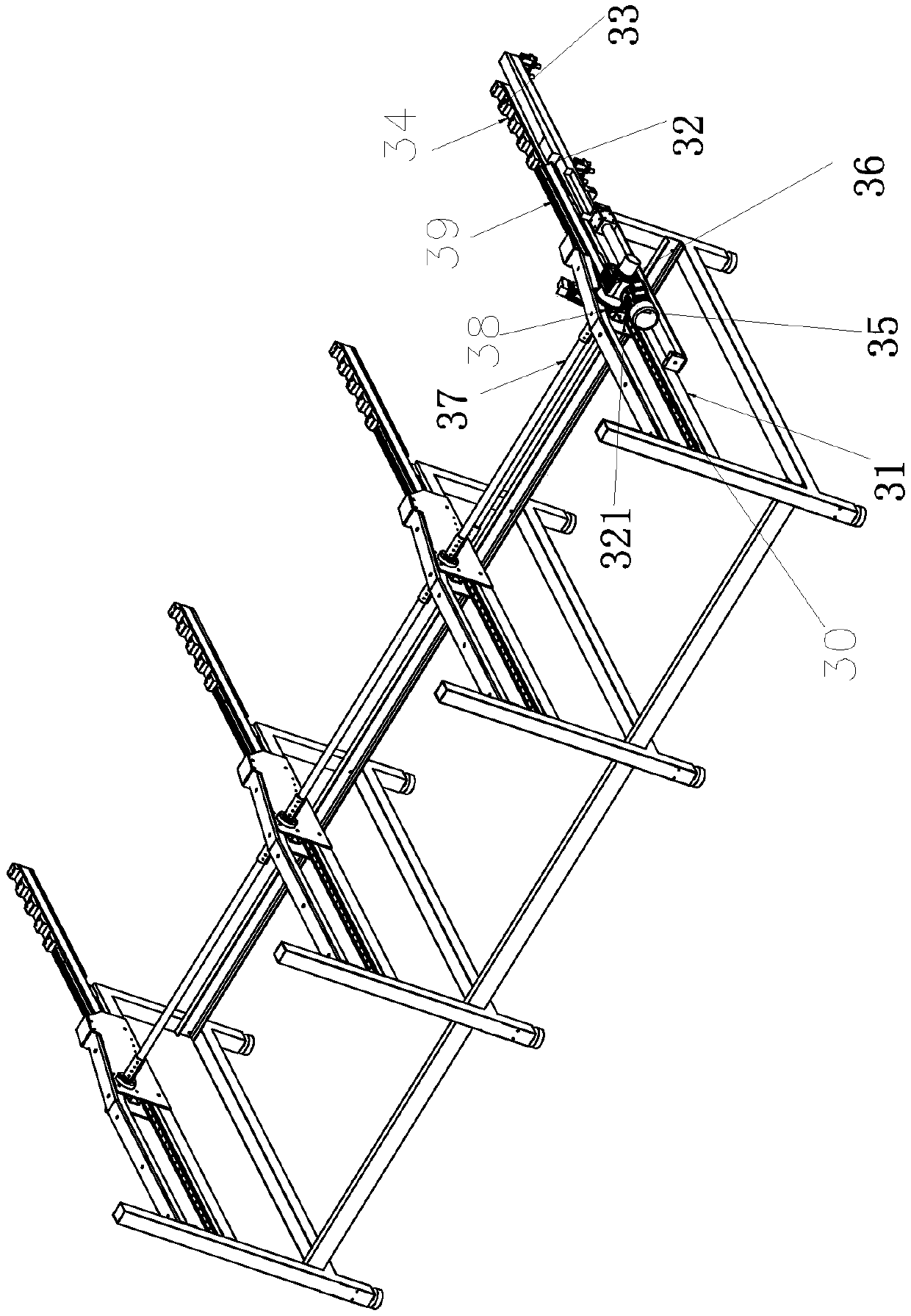

[0022] Such as Figure 1-Figure 5 As shown, the present invention provides a hydraulic testing machine for multiple steel pipes, which includes a frame 1, a plurality of clamping mechanisms 2 for clamping steel pipes are arranged in the frame 1, and one side of the frame 1 There is a feeding mechanism 3 that pushes the steel pipe to the clamping mechanism 2, and a feeding mechanism 4 is provided on the other side. One end of the frame 1 is provided with a fixing mechanism 5, and the other end is provided with a moving mechanism that pushes the steel pipe to the fixing mechanism 5. Mechanism 6, said fixing mechanism 5 is provided with a hydraulic system 7 for pressurizing the steel pipe. In the above scheme, when the steel pipe is tested for pressure, the steel pipe is first fed to the clamping mechanism 2 through the feeding mechanism 3, the steel pipe can be clamped by the clamping mechanism 2, and the steel pipe is driven by the moving mechanism 6 to move to the fixing mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com