Motor and lens group for driving liquid lens

A liquid lens and motor technology, applied in installation, optics, focusing devices, etc., can solve the problems of high production cost and complex lens group structure, and achieve the effect of sensitive curvature, sensitive adjustment function, and uniform deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

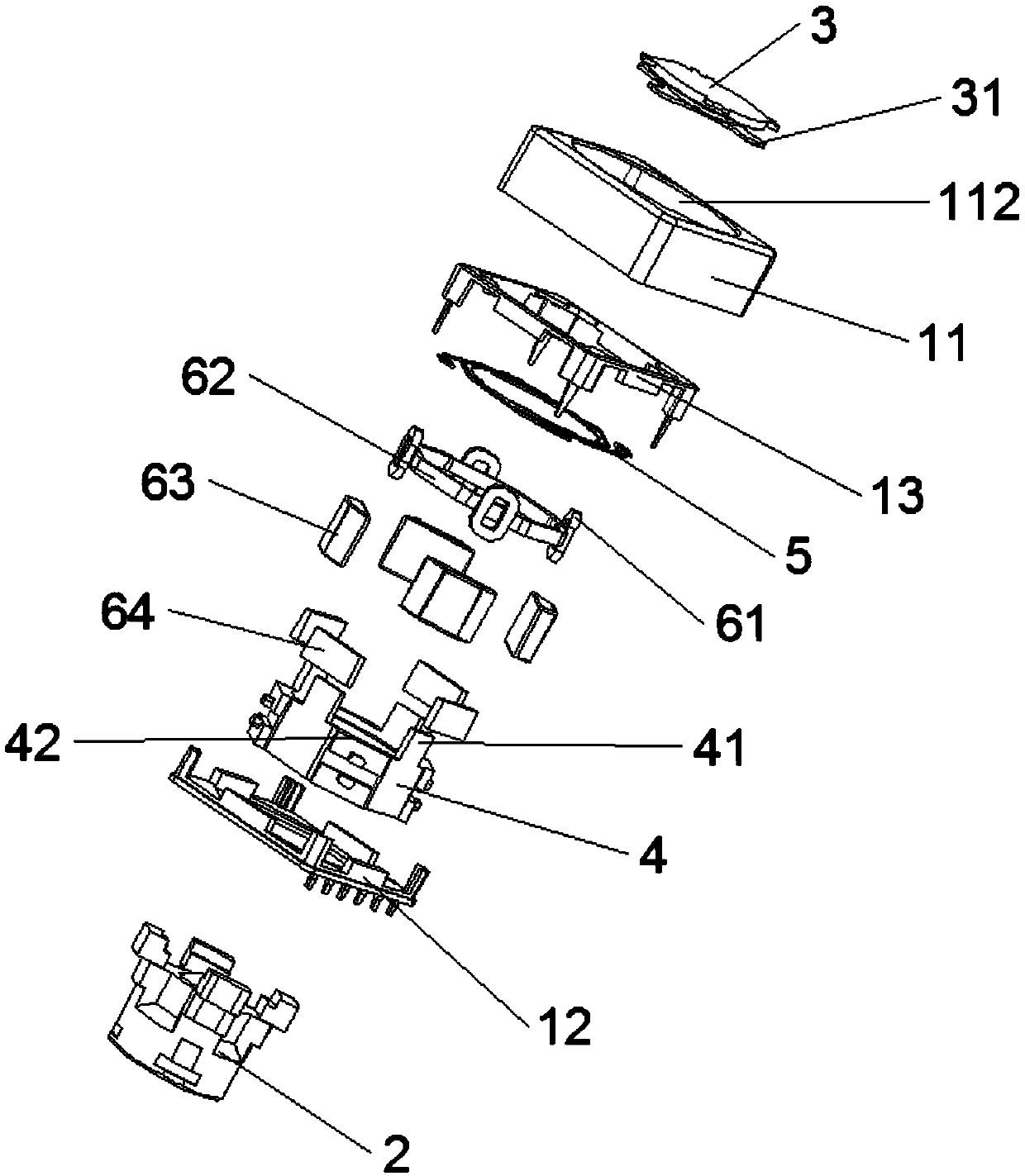

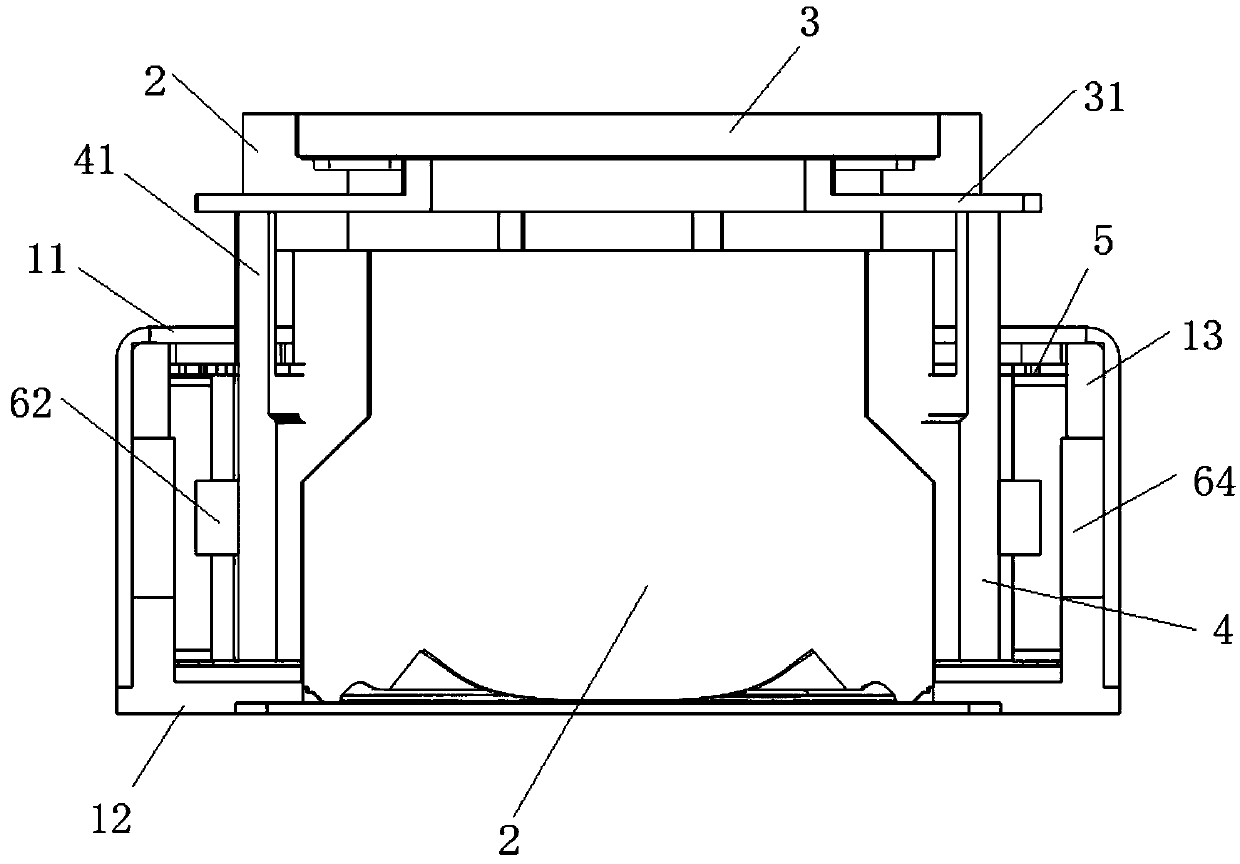

[0029] The motor of the driving liquid lens 3 of the present embodiment, refer to figure 1 As shown, it includes a seat body, a bracket 31 , a carrier 4 , a driving assembly and a second reset member 5 .

[0030] The base body is used for fixing and installing the first lens 2 and the liquid lens 3 that are distributed along the optical axis and arranged correspondingly. It includes a lower cover 12, and an upper cover 11 fixedly connected with the lower cover 12, the upper cover 11 has an accommodating cavity for setting the carrier 4, the first lens 2 and the drive assembly, and a supply for The first lens 2 and the carrier 4 protrude from the cavity opening of the accommodating cavity. In this embodiment, the cavity opening is a through hole 112 adapted to the shapes of the liquid lens 3 , the first lens 2 and the carrier 4 . In order to prevent the magnetic induction leakage in the driving assembly from affecting other parts outside the base, such as other parts on the mobi...

Embodiment 2

[0042] The lens group of this embodiment includes the motor for driving the liquid lens 3 in the first embodiment, the first lens 2 and the liquid lens 3 .

[0043] The first lens 2 is fixedly mounted on the lower cover 12 and is located in the receiving cavity, and is an optical lens. The carrier 4 is sleeved on the outside of the first lens 2 .

[0044] The liquid lens 3 includes a lens body, a movable plate and liquid arranged in the lens body. The movable plate moves relative to the lens body to adjust the shape of the liquid, and then adjust the curvature of the liquid lens 3 . The lens body is fixedly installed on the first lens 2 , and the first lens 2 is fixedly installed on the lower cover 12 , that is, the liquid lens 3 is installed on the base through the first lens 2 . The first lens 2 and the liquid lens 3 are distributed along the optical axis and arranged correspondingly, the distance between the first lens 2 and the liquid lens 3 is fixed, that is, the focal le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com