Curvature-adjustable abrasive-belt grinding wheel

An abrasive belt and grinding wheel technology, applied in the field of machinery, can solve the problems of large occupied space, small room for transformation, low work efficiency, etc., and achieve the effects of precise adjustment, small occupied volume and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

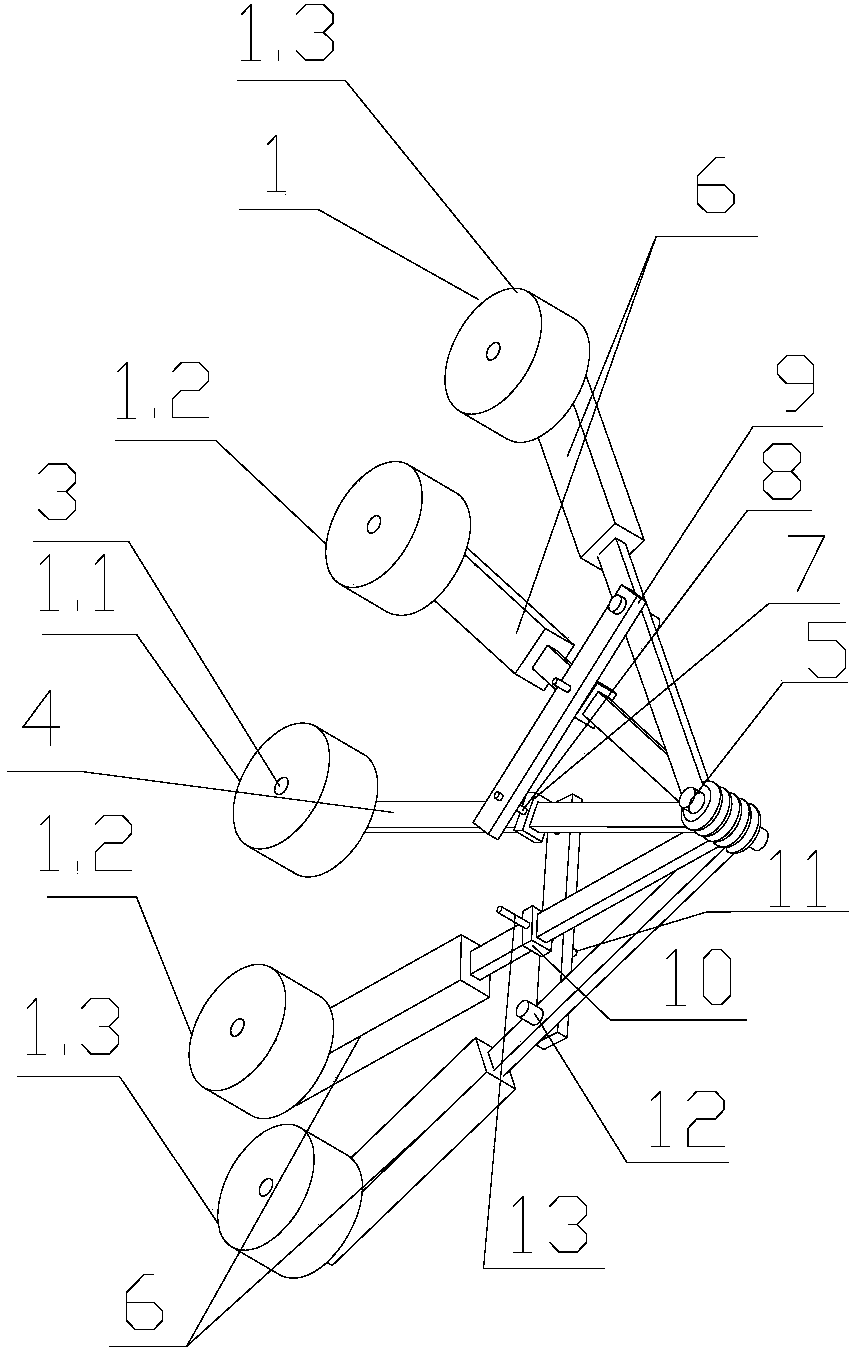

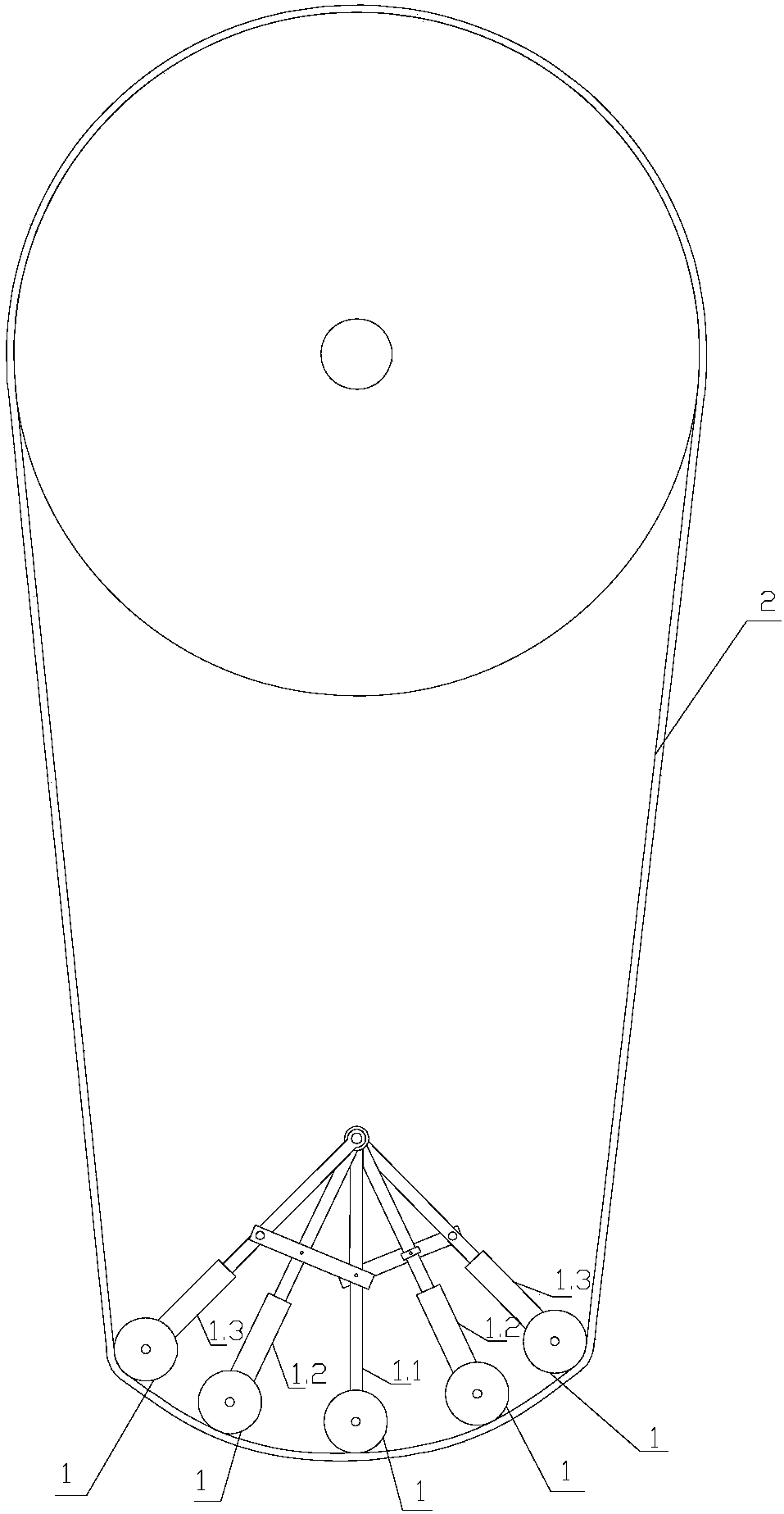

[0012] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to the embodiments. An abrasive belt grinding wheel conversion mechanism with adjustable curvature is arranged on the inner side of the abrasive belt 2 in the polishing machine, and is characterized in that: it includes a polishing wheel 1, and the polishing wheel 1 is used to abut against the back of the abrasive belt 2 and to be positioned. The polishing wheel is divided into a main polishing wheel 1.1, two No. 1 polishing wheels 1.2 and two No. 2 polishing wheels 1.3, the No. 1 polishing wheel 1.2 is located on both sides of the main polishing wheel 1.1, and the No. 2 polishing wheel 1.3 is located Both sides of No. 1 polishing wheel 1.2, described main polishing wheel 1.1 is installed on the square main bar 4 by polishing wheel shaft 3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com