Deep groove ball bearing outer ring groove grinder grinding wheel dresser

A technology of deep groove ball bearing and grinding wheel dresser, which is applied in the directions of grinding machine parts, grinding/polishing equipment, abrasive surface adjustment devices, etc. problems, to achieve the effect of convenient ultra-finishing, improving product quality, and accurate curvature adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

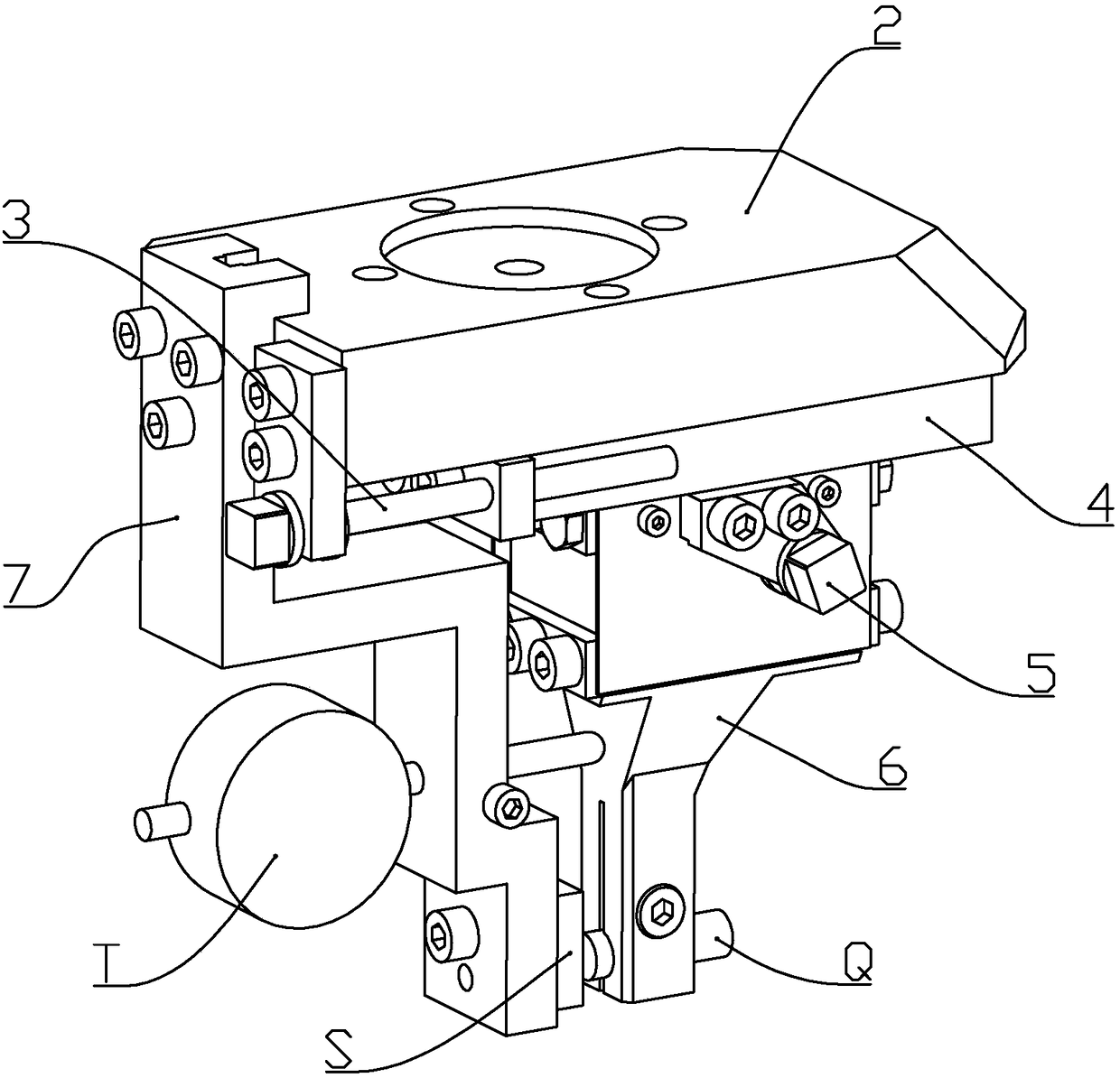

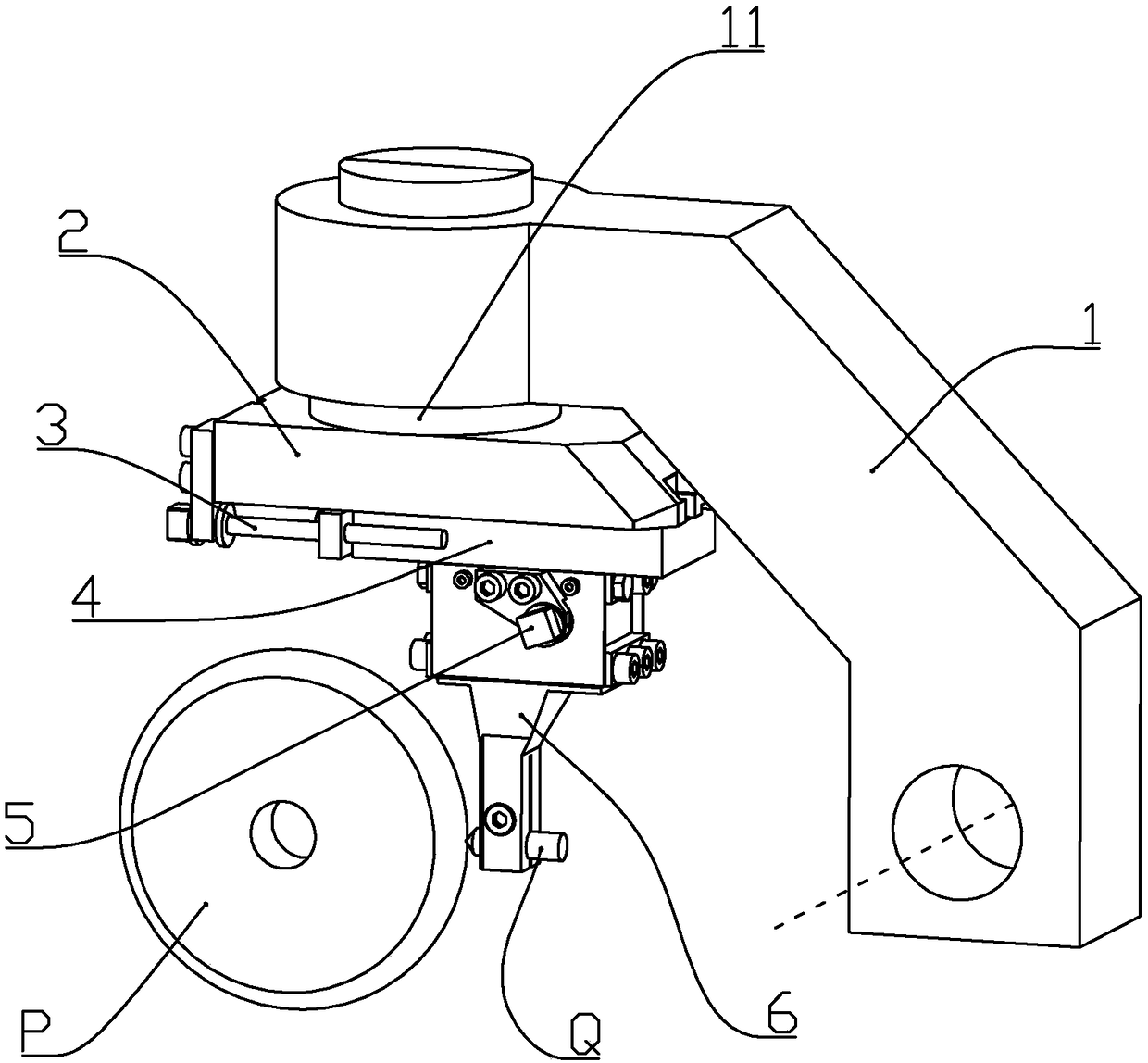

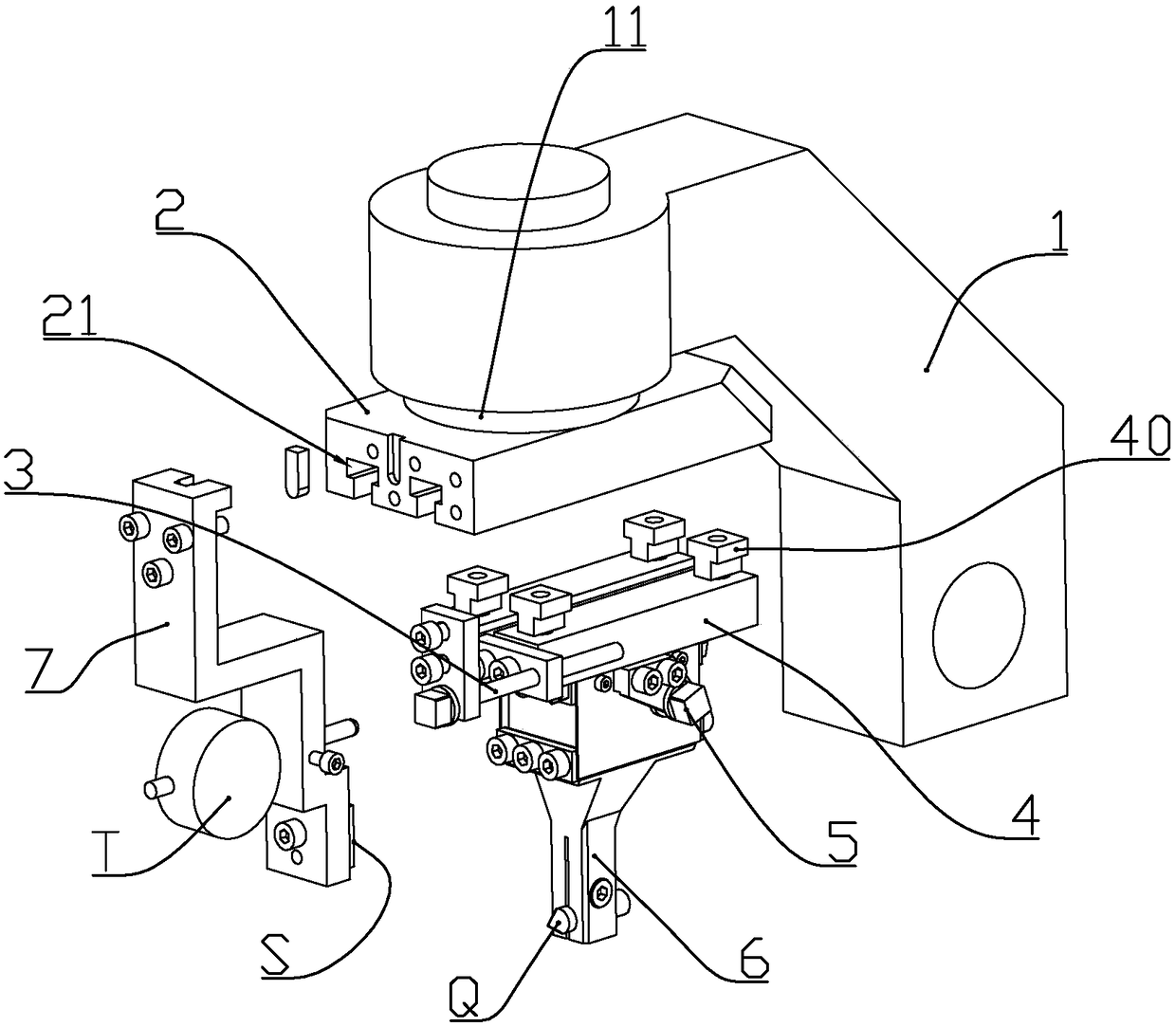

[0049] according to Figure 1 to Figure 9As shown, a deep groove ball bearing outer ring groove grinder grinding wheel dresser described in this embodiment includes a sliding seat 2, an upper bracket 4 that is slidably connected under the sliding seat, and is connected between the sliding seat and the upper bracket The coarse adjustment screw 3, the lower bracket 6 arranged under the upper bracket, the fine-tuning device 5 connected between the upper bracket and the lower bracket, the positioning frame 7 detachably connected to the side of the sliding seat, and the diamond pen connected to the lower bracket Q, the curvature standard block S connected to the positioning frame and opposite to the tip of the diamond pen, and the dial indicator T connected to the positioning frame.

[0050] A connecting seat 41 is fixedly connected to the lower end of the upper bracket, and a lateral sliding groove 42 is formed under the rear part of the connecting seat.

[0051] The front part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com