coil device

A coil device and winding technology, applied in the direction of transformer/inductor coil/winding/connection, circuit, electrical components, etc., can solve the problems of blockage, difficulty in increasing the number of windings, poor heat dissipation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] Hereinafter, the present invention will be described based on the embodiments shown in the drawings.

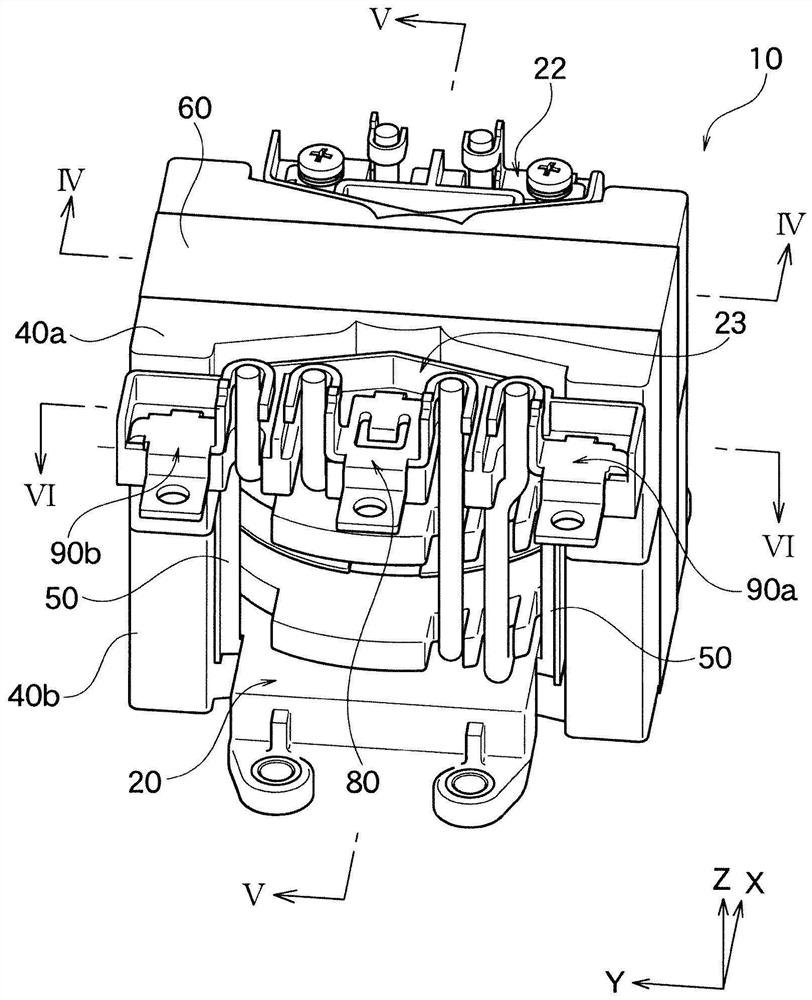

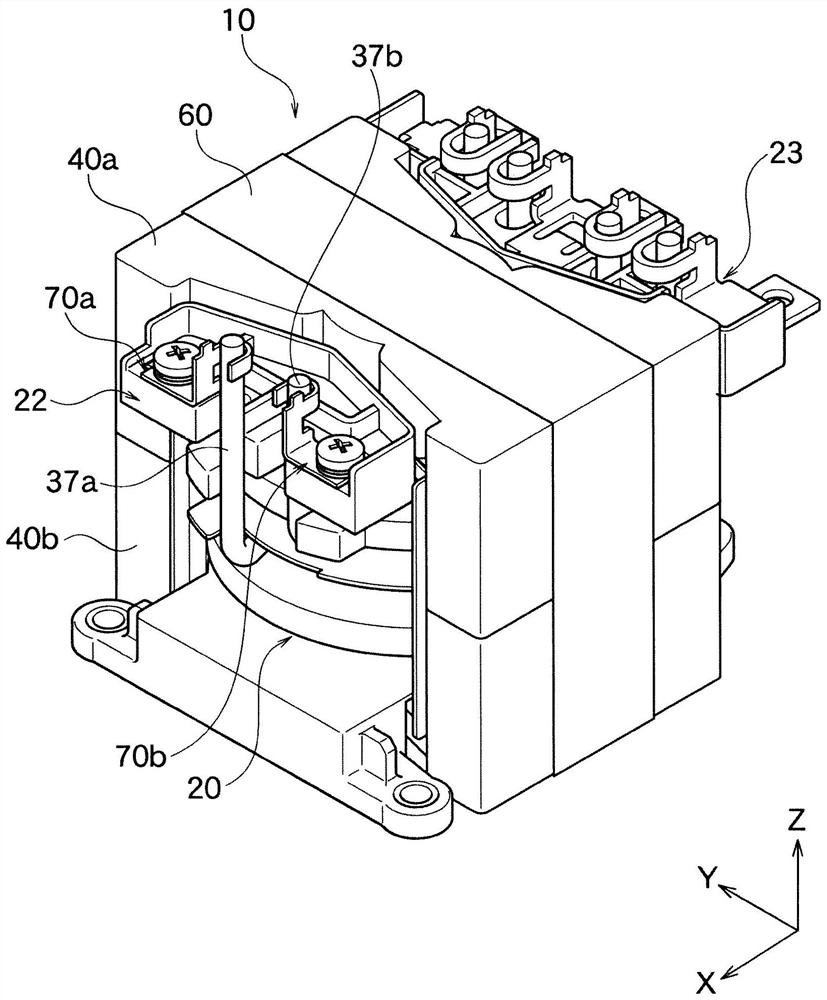

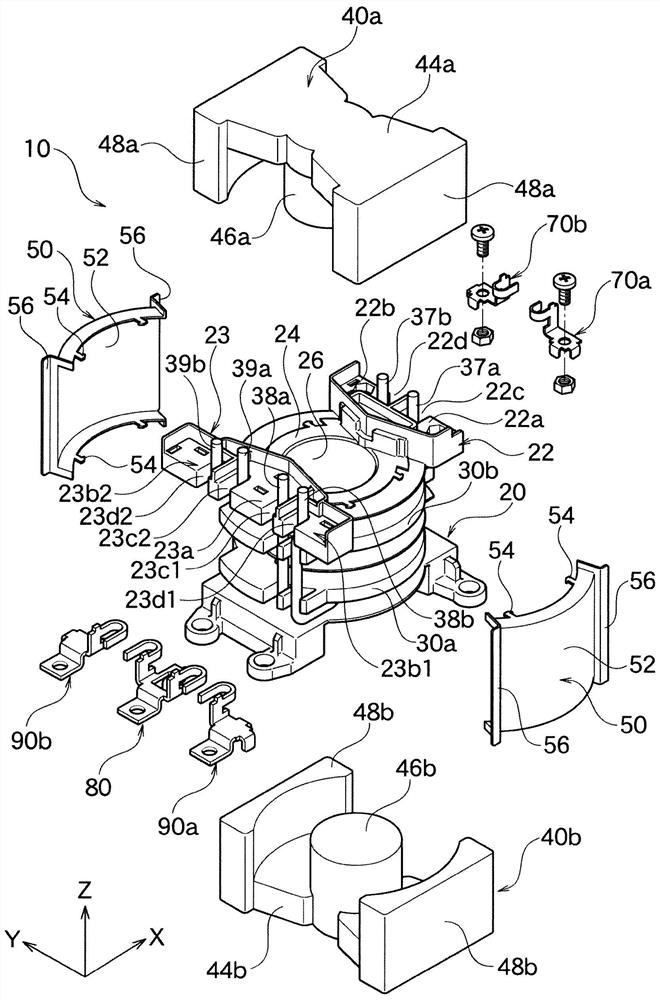

[0077] as Figure 1A as well as Figure 1B The shown transformer 10 of the coil device according to the present embodiment is used, for example, as a leaky transformer or the like for a seated object such as an automobile or the like. This transformer 10 has a skeleton 20 , magnetic cores 40 a , 40 b , a cover 50 , and a tape member 60 .

[0078] Such as figure 2 As shown, the frame 20 has a frame body 24 , and a first terminal block 22 and a second terminal block 23 integrally formed on the upper part in the Z-axis direction at both ends of the frame body 24 in the X-axis direction. On the first terminal base 22, terminal mounting portions 22a and 22b are formed at both ends in the Y-axis direction, and the first terminal 70a and the second terminal 70b are attached to these portions. The first winding wire 37 described later ( Figure 3A ), that is, a pair of fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com