Station lock crank three-station mechanism

A three-station, station technology, applied in the field of three-station mechanism of the station lock crank, can solve the problems of complex structure design, limit, poor interlock structure design, etc., to achieve reasonable structural design and good safety , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

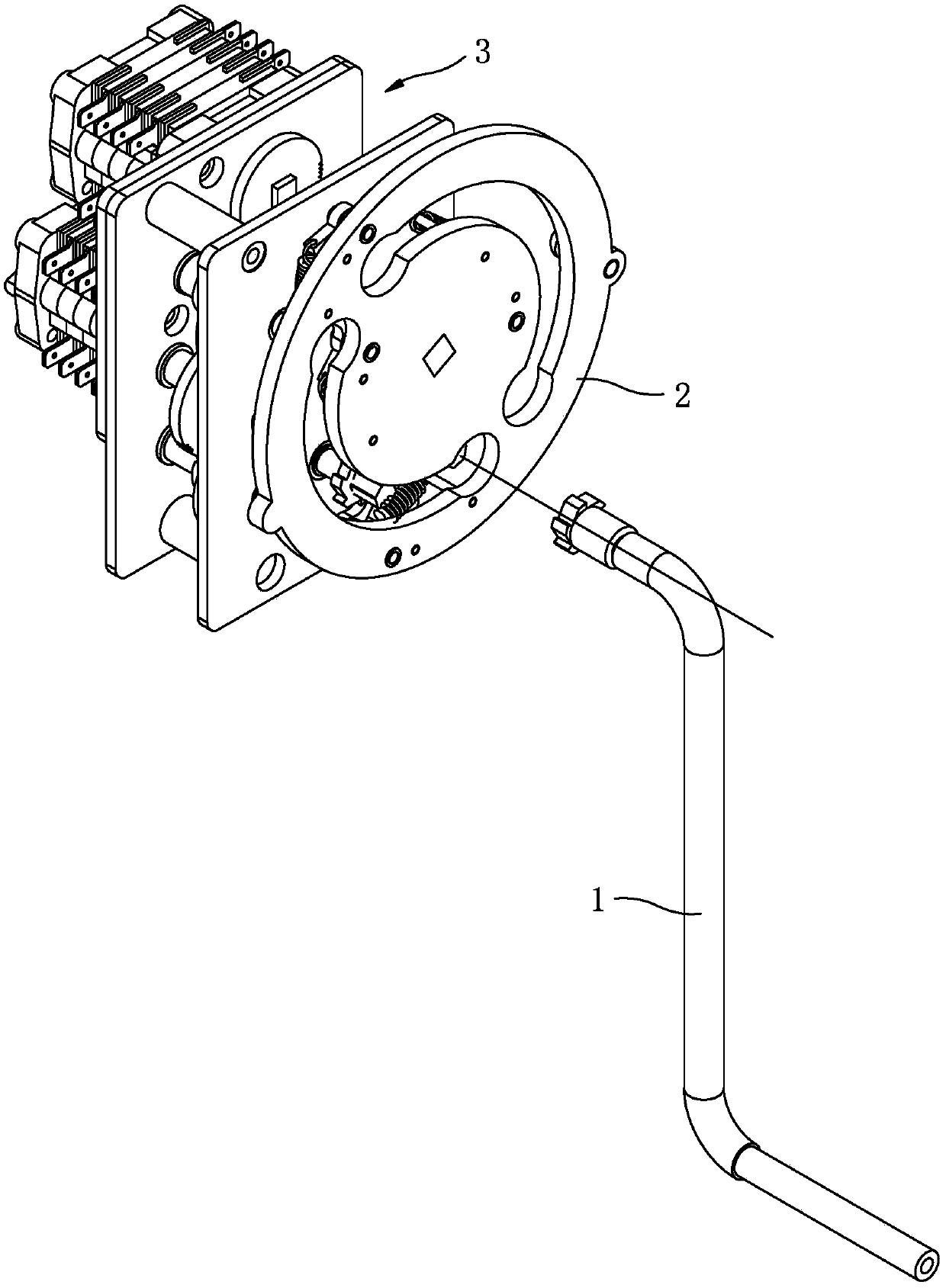

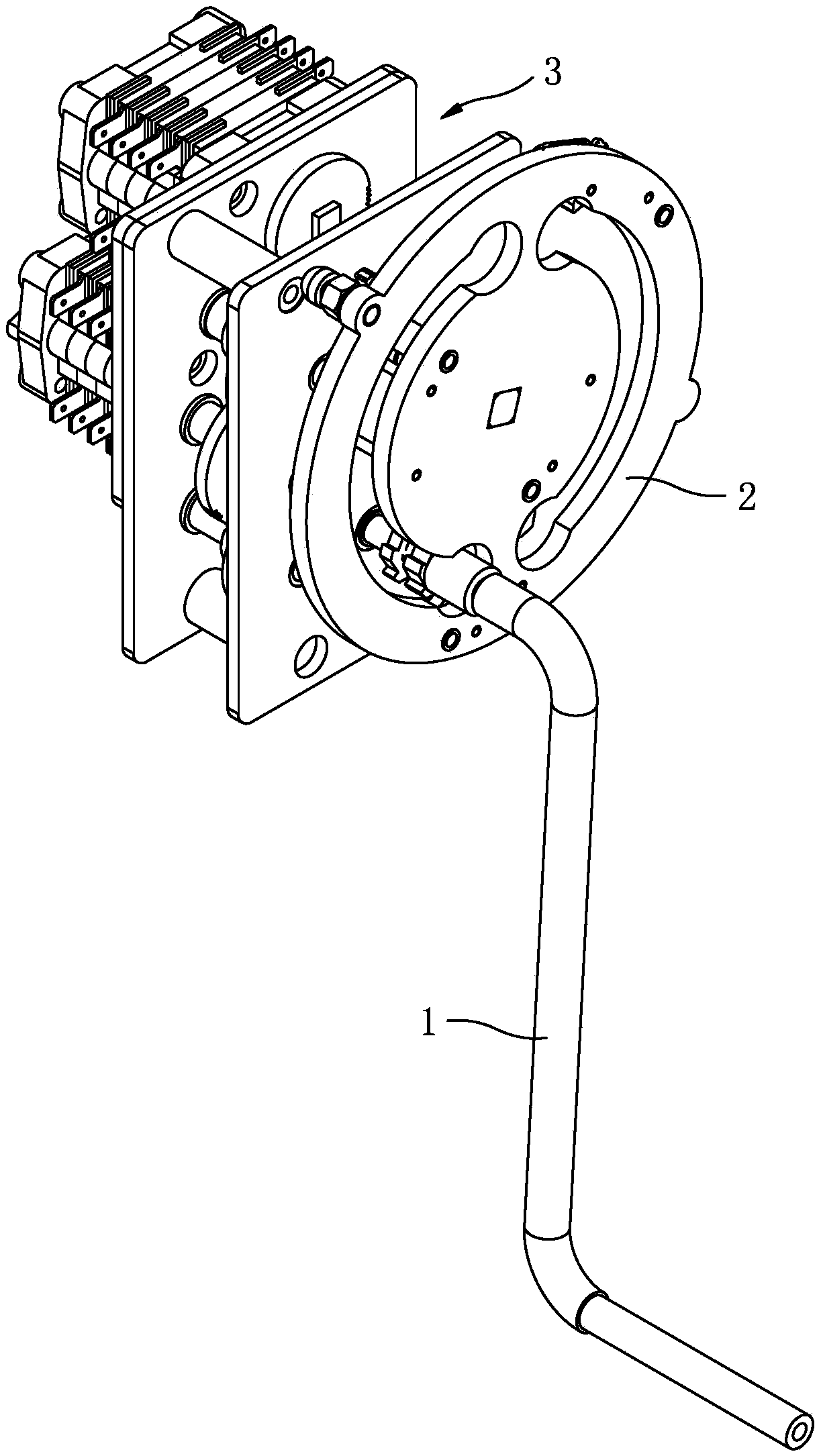

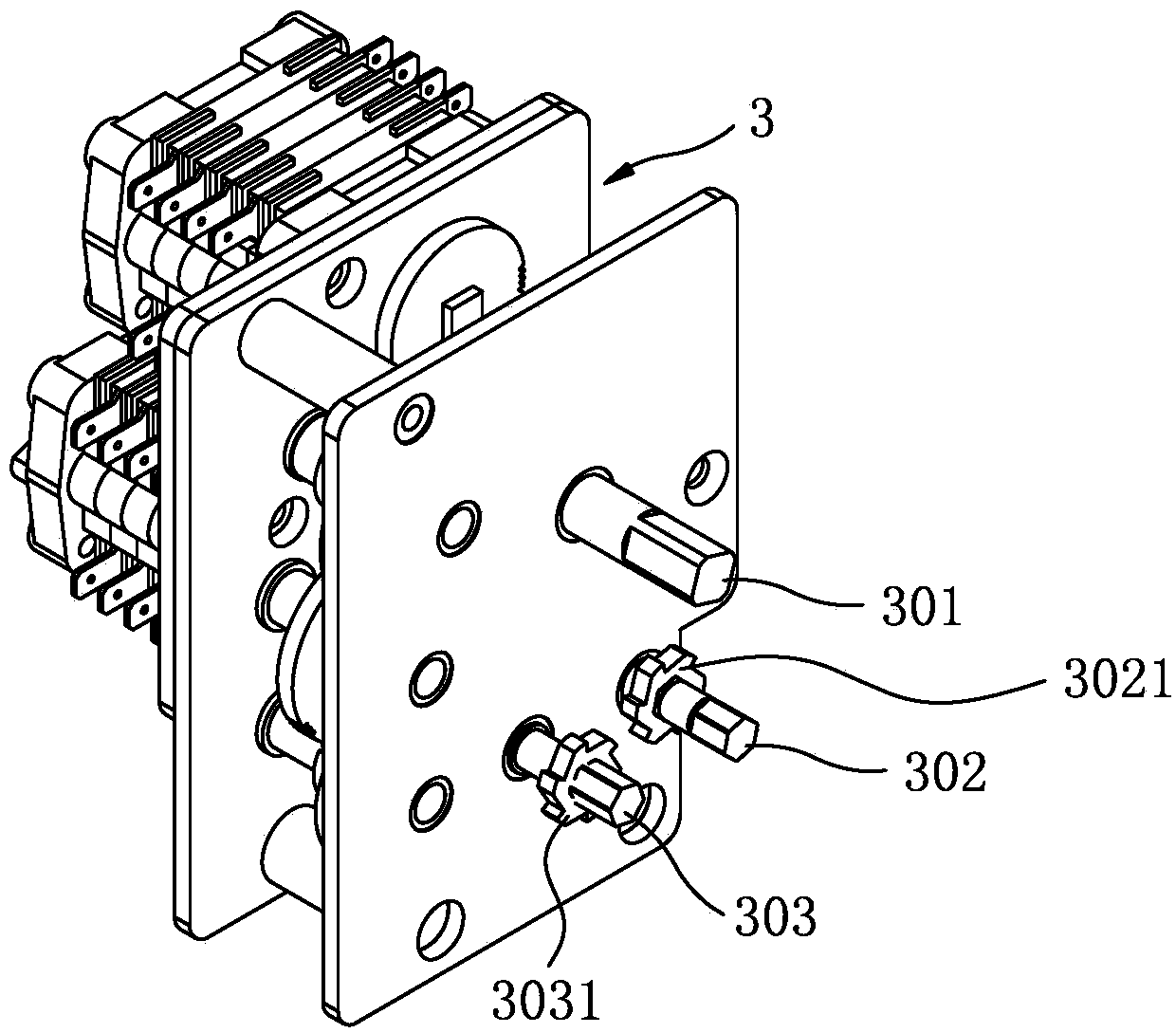

[0021] Now in conjunction with the accompanying drawings, the structure and use of the present invention will be further described. Such as Figure 1-Figure 5 As shown, one side of the gearbox 3 of the three-station mechanism protrudes from the disk installation shaft 301 of the front side plate, the grounding switch operation shaft 302 and the isolation switch operation shaft 303. The installation shaft is fixedly connected; both sides of the shaft hole of the station identification disc are symmetrically provided with arc-shaped sliding holes, and the two ends of the arc-shaped sliding holes are respectively provided with insertion holes for the ratchet handle 1, and the arc-shaped sliding holes are the ratchet handles. Align the pawl limit groove and the opposite side of the arc-shaped slide hole with the operating shaft of the earthing switch and the isolating switch of the gearbox respectively, and extend into the arc-shaped slide hole; the isolation below the arc-shaped ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap