New-type enhanced semiconductor device and preparation method thereof

A semiconductor, enhancement-mode technology, used in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem that the selective growth of p-GaN materials is difficult to control, the concentration of holes in the p-GaN layer is not high, and the quality of epitaxial crystals is affected. and other problems, to achieve the effect of high stability, reduced requirements, and high conduction capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

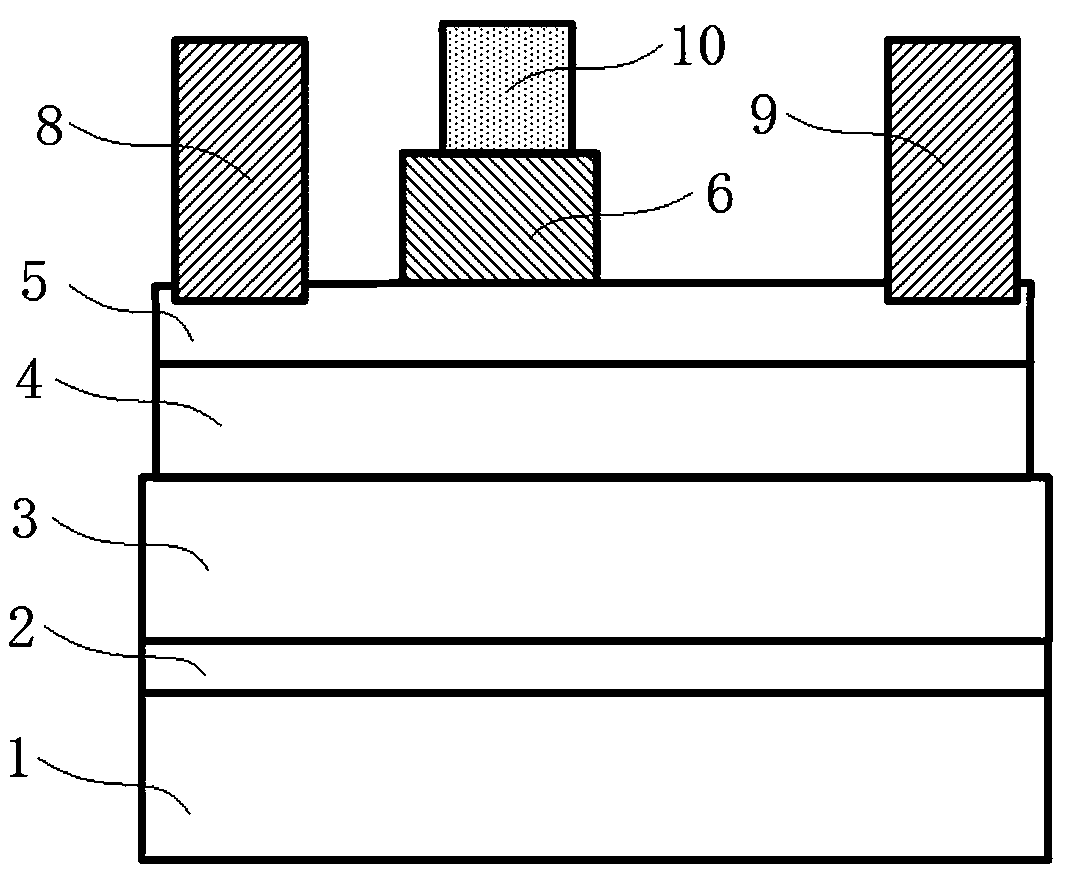

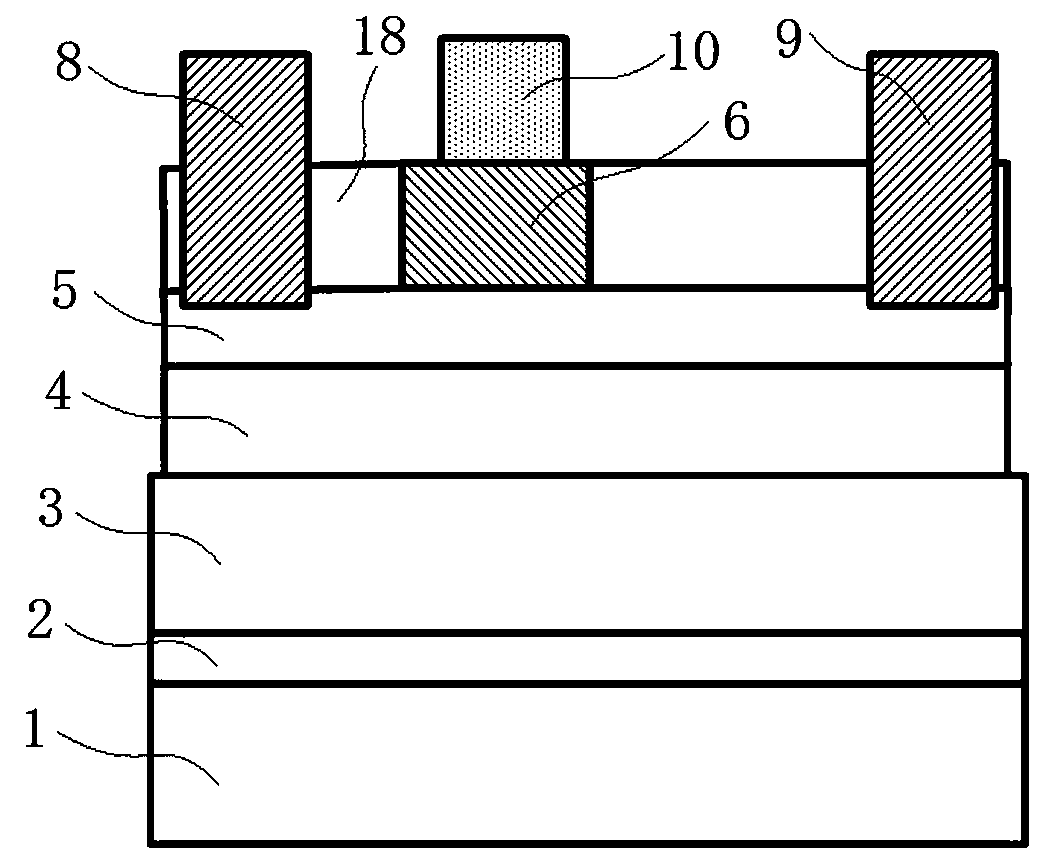

[0055] Such as Figure 12 Shown is a schematic diagram of the device structure of this embodiment, a semiconductor enhancement transistor, including a substrate 1 , a semiconductor epitaxial layer grown on the substrate 1 , a gate 10 , a source 8 and a drain 9 . The epitaxial layer includes, from bottom to top, a nitride nucleation layer 2, a nitride stress buffer layer 3, a nitride channel layer 4, a primary epitaxial nitride barrier layer 5, and a p-type nitride layer 6 and a secondary epitaxial layer. Nitride barrier layer 7 . The p-type nitride layer 6 remains only on the primary epitaxial nitride barrier layer 5 in the region of the gate 10 to realize the pinch-off of the two-dimensional electron gas channel under the gate 10 . The secondary epitaxy has no mask, and the secondary epitaxial nitride barrier layer 7 is grown on the primary epitaxial barrier layer and the p-type nitride layer 6 in the region of the gate 10 .

[0056] The fabrication method of the above-ment...

Embodiment 2

[0070] Such as Figure 13 Shown is a schematic diagram of the device structure of this embodiment, which differs from the structure of Embodiment 1 only in that a layer of AlN space is sandwiched between the nitride channel layer 4 and the primary epitaxial nitride barrier layer 5 in Embodiment 2. The isolation layer 11 has a thickness of 0.3-3 nm. It is used to improve the two-dimensional electron gas characteristics of the channel.

Embodiment 3

[0072] Such as Figure 14 Shown is a schematic diagram of the device structure of this embodiment, which differs from the structure of Embodiment 1 only in that: Embodiment 1 is middle, and part of the primary epitaxial nitride barrier layer 5 outside the gate 10 region is removed, while Embodiment 3 Part of the primary epitaxial nitride barrier layer 5 outside the region of the middle gate 10 remains intact. Compared with Example 1, Example 3 requires a harsher etching scheme, such as more advanced equipment, or self-terminating etching conditions containing oxygen or fluorine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com