Hetetrostructure field effect diode and manufacturing method thereof

A technology of field-effect diodes and heterostructures, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve difficult problems such as low conduction voltage and low reverse leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

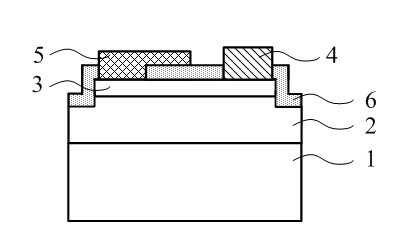

[0034] figure 1 It is a schematic structural diagram of an AlGaN / GaN heterojunction field effect diode according to the first embodiment of the present invention.

[0035] Such as figure 1 As shown, the substrate 1 can be sapphire Sapphire, silicon Si, silicon carbide SiC, gallium nitride GaN, gallium arsenide GaAs substrate, etc. Located on the substrate 1 is a high-resistance GaN layer 2, which may be a doped or non-doped layer or a combination of layers, with a thickness between 200 nanometers and 10 microns. Located on the high-resistance GaN layer 2 is an AlGaN barrier layer 3 with a thickness between 2-50 nanometers. A 2DEG channel is formed between the AlGaN barrier layer 3 and the high-resistance GaN layer 2, and the concentration is 10 10 -10 14 / cm 2 between.

[0036] The insulating dielectric layer 6 located on the AlGaN barrier layer 3, the insulating dielectric layer 6 has at least one layer of insulating material with a high dielectric constant, and the thi...

Embodiment 2

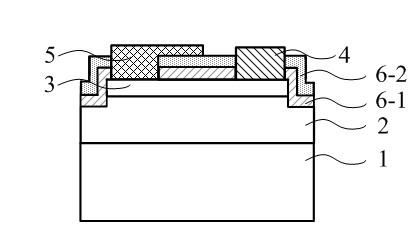

[0040] figure 2 It is a schematic structural diagram of an AlGaN / GaN heterojunction field effect diode in the second example of the present invention.

[0041] The structure in this embodiment is basically the same as that in Embodiment 1, the difference is that: a structure of two insulating dielectric layers 6 is adopted, wherein layer 6-1 is a low dielectric constant material, and layer 6-2 is a material with a higher dielectric constant Material.

[0042] The first layer of the insulating dielectric layer adopts a low dielectric constant dielectric layer 6-1, which is SiO in this embodiment 2 , and the thickness is between 2-10 nanometers, the purpose is to optimize and improve the quality of the growth interface of the insulating dielectric layer; the second layer adopts the high dielectric constant dielectric layer 6-2, and selects Al in this embodiment 2 o 3 , with a thickness of 5-20 nm. The purpose of selecting the dielectric layer 6-2 with high dielectric consta...

Embodiment 3

[0044] The present invention also provides a method for manufacturing a heterostructure field effect diode, which includes the following steps:

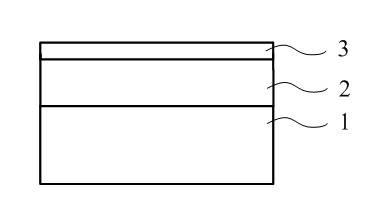

[0045] A. As shown in FIG. 3( a ), there are substrate 1 , insulating high-resistance semiconductor 2 , and wide-gap heterostructure barrier layer 3 in sequence.

[0046] B. As shown in FIG. 3( b ), after the pattern of the active region is formed by photolithography, an isolation mesa is formed by etching to realize electrical isolation of the active region.

[0047] C. As shown in Figure 3(c), one or more layers of insulating dielectric layer 6 are deposited on the isolation table, and the number of layers and the thickness of each layer can be adjusted according to needs;

[0048] D. As shown in Figure 3(d), the electrode pattern is first photoetched on the table by photolithography, and then the insulating dielectric layer 6 is etched to form a window for electrode evaporation by dry or wet etching. For the next step to evaporat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com