Power connector and assembly method thereof

A technology for power connectors and socket slots, which is applied to the components, connections, and assembly/disassembly of contact pieces of connection devices. The effect of taking into account the convenience of assembly and thinning requirements, improving assembly strength, and reducing the probability of false touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

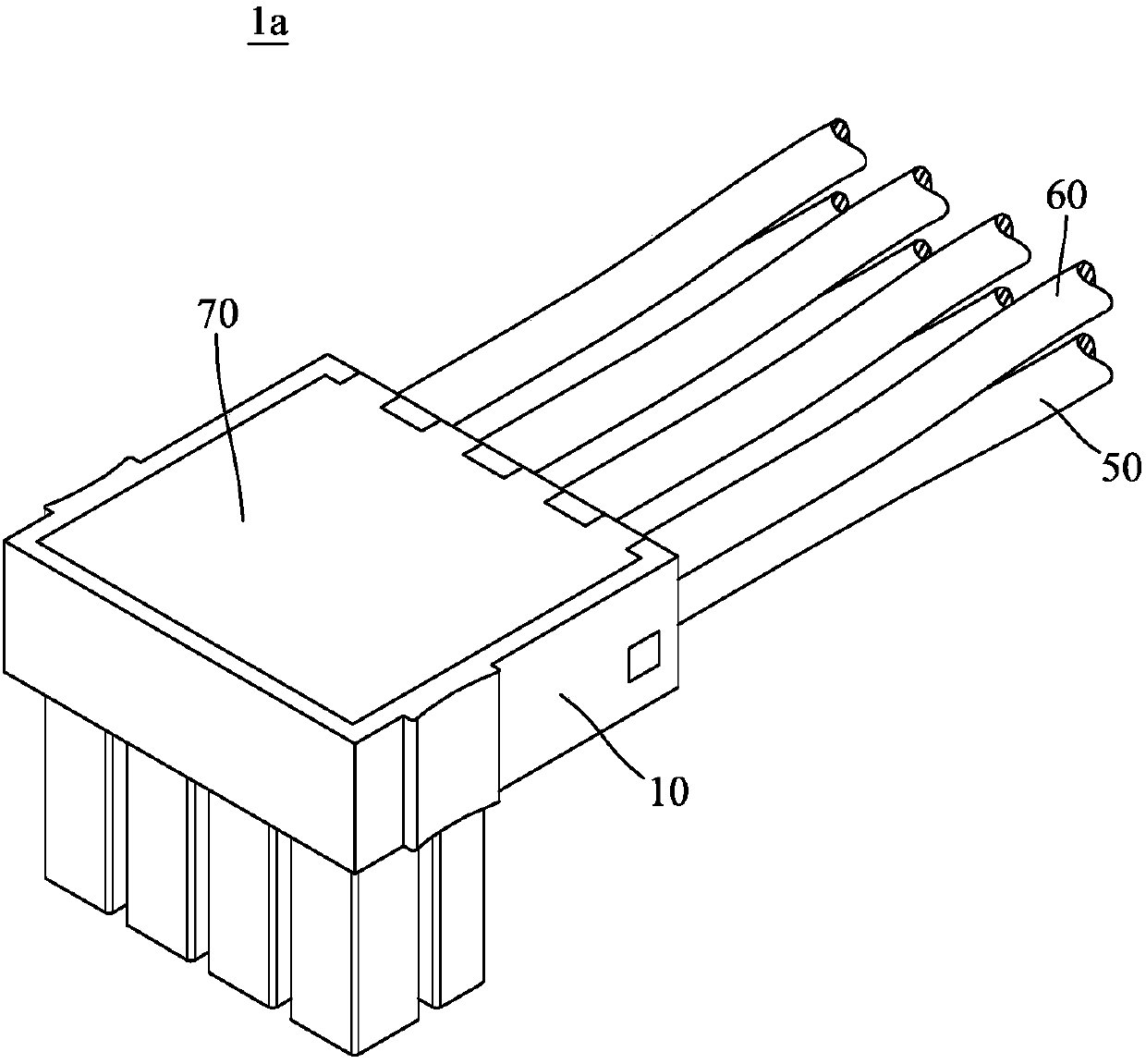

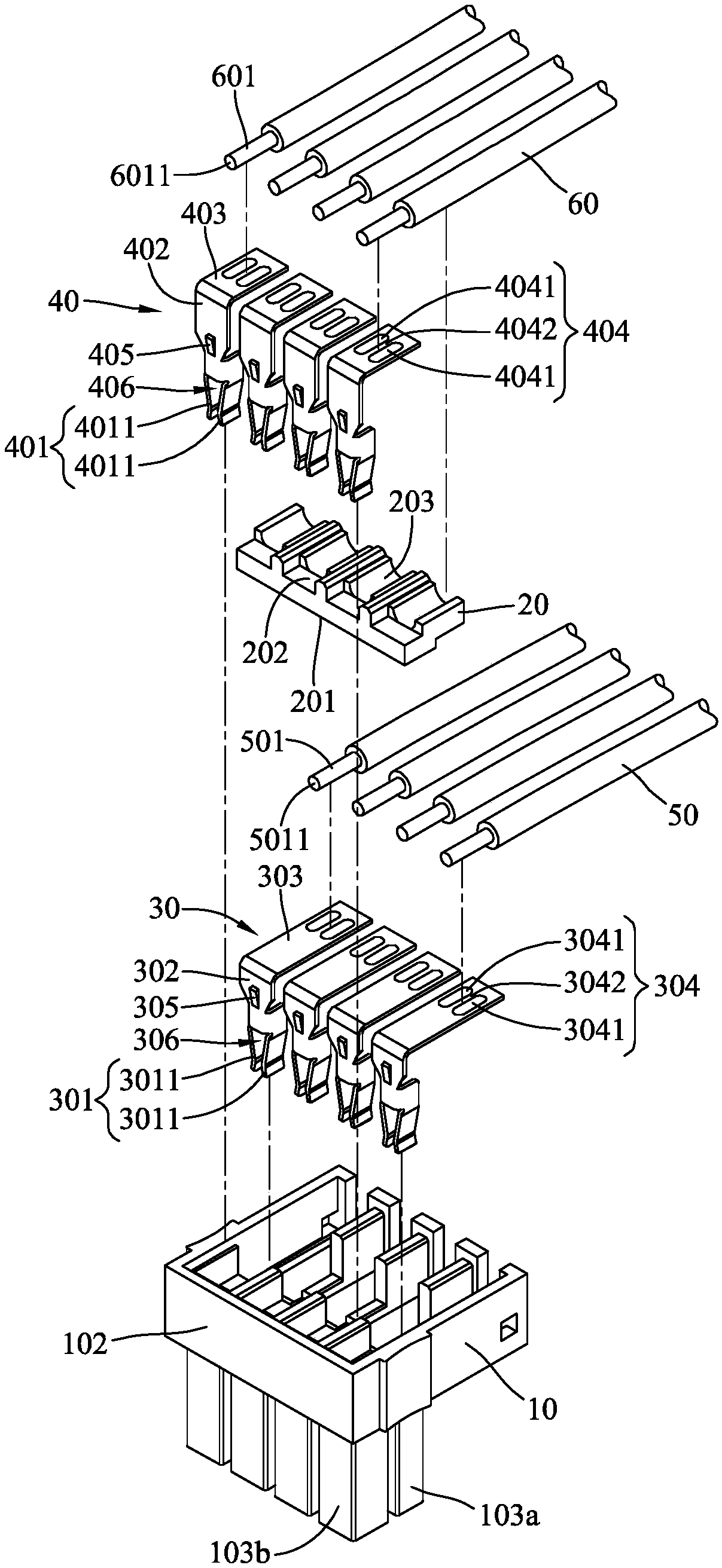

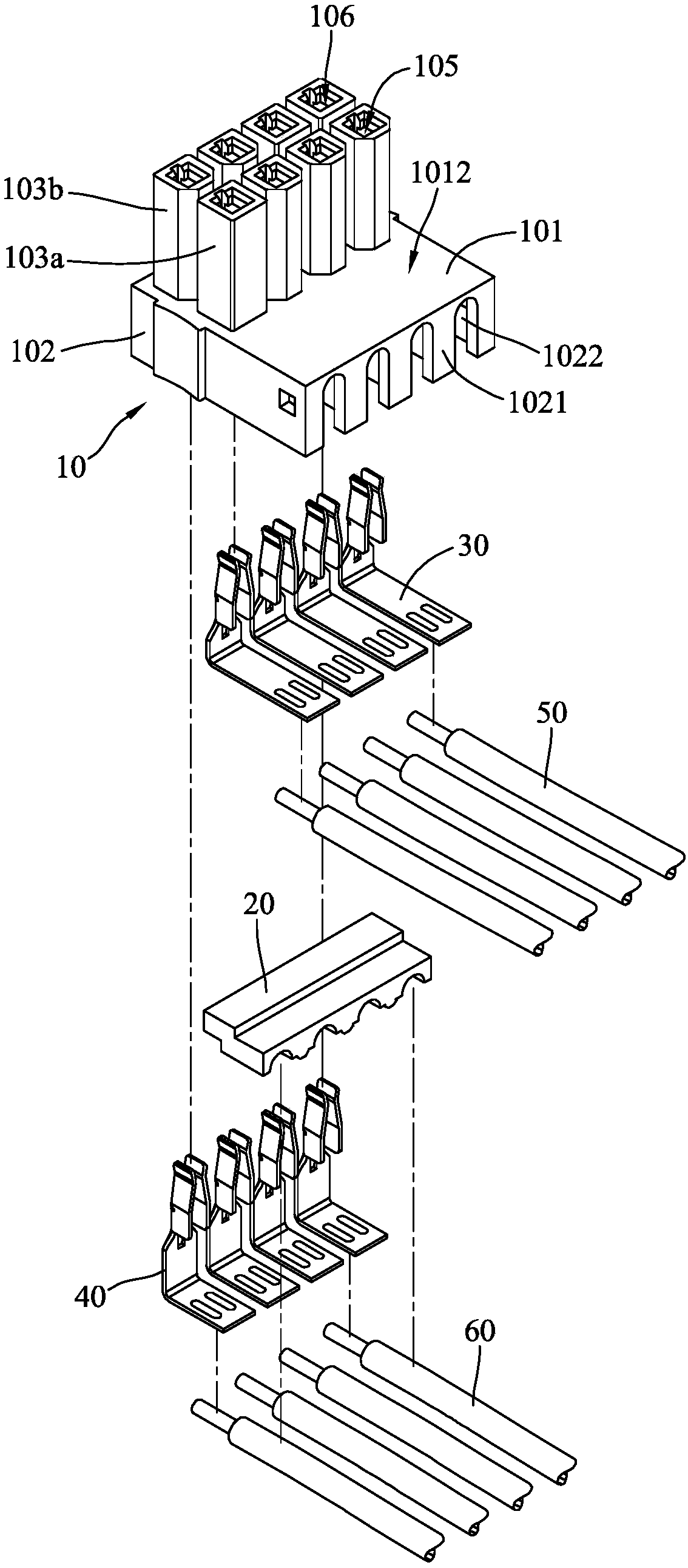

[0073] see Figure 1 to Figure 5 . figure 1 It is a three-dimensional schematic view of the power connector according to the first embodiment of the present invention. figure 2 for figure 1 An exploded view of an unfilled power connector. image 3 for figure 1An exploded view of another view of the power connector without filling. Figure 4 for figure 1 A cross-sectional schematic diagram of a power connector plugged into a mating connector. Figure 5 for figure 1 A schematic cross-sectional view of the housing of the power connector.

[0074] In this embodiment, the power connector 1a includes a housing 10, a partition 20, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com