PERMANENT MAGNET ROTOR, METHOD FOR PRODUCING SAME, AND magnetization device

A permanent magnet rotor and equipment technology, applied in the direction of magnetic circuit rotating parts, manufacturing motor generators, manufacturing stator/rotor body, etc., can solve the problems of magnetic field strength limitation, some areas of magnets are not completely magnetized, etc., and achieve high The effect of magnetizing field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

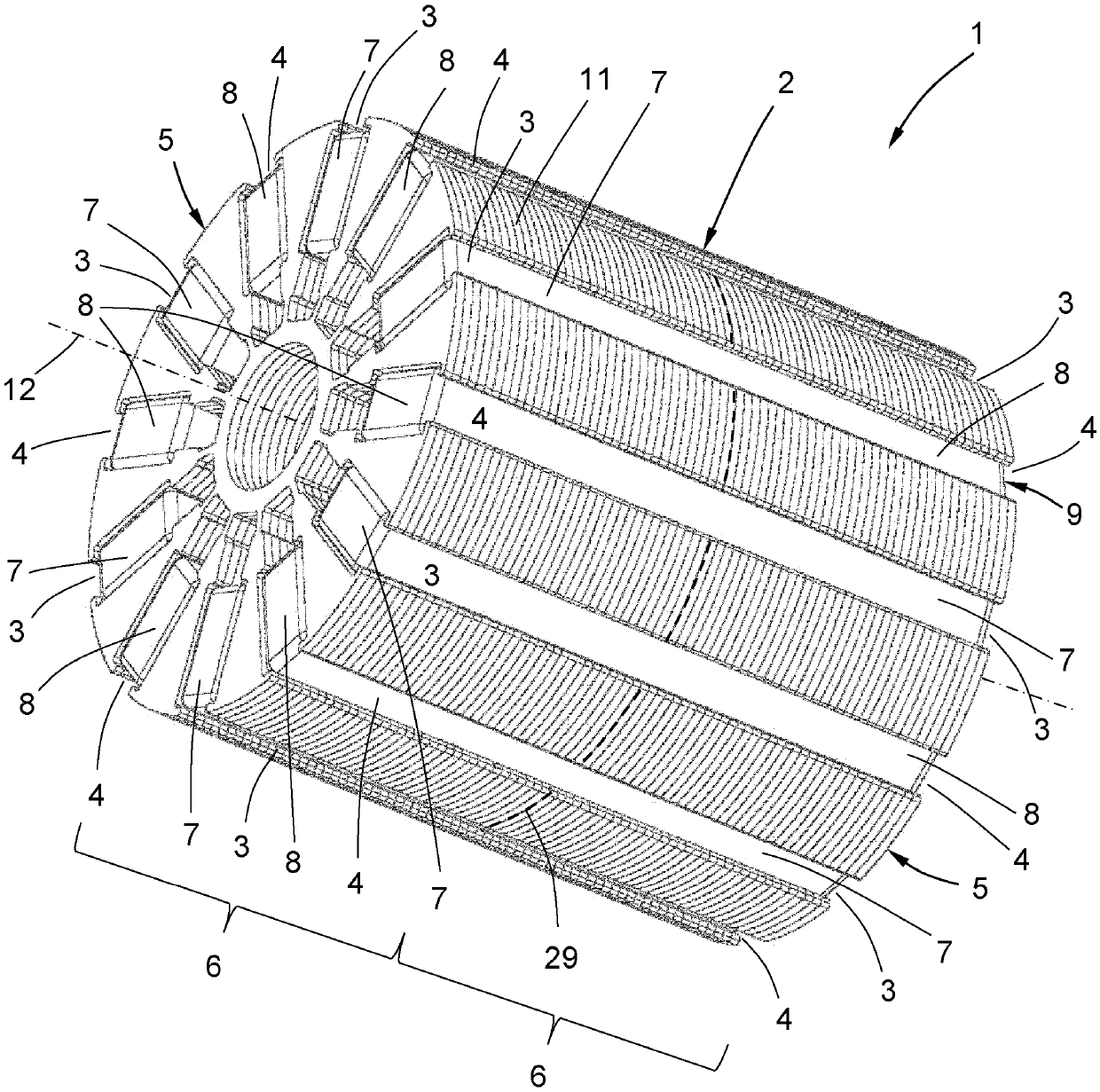

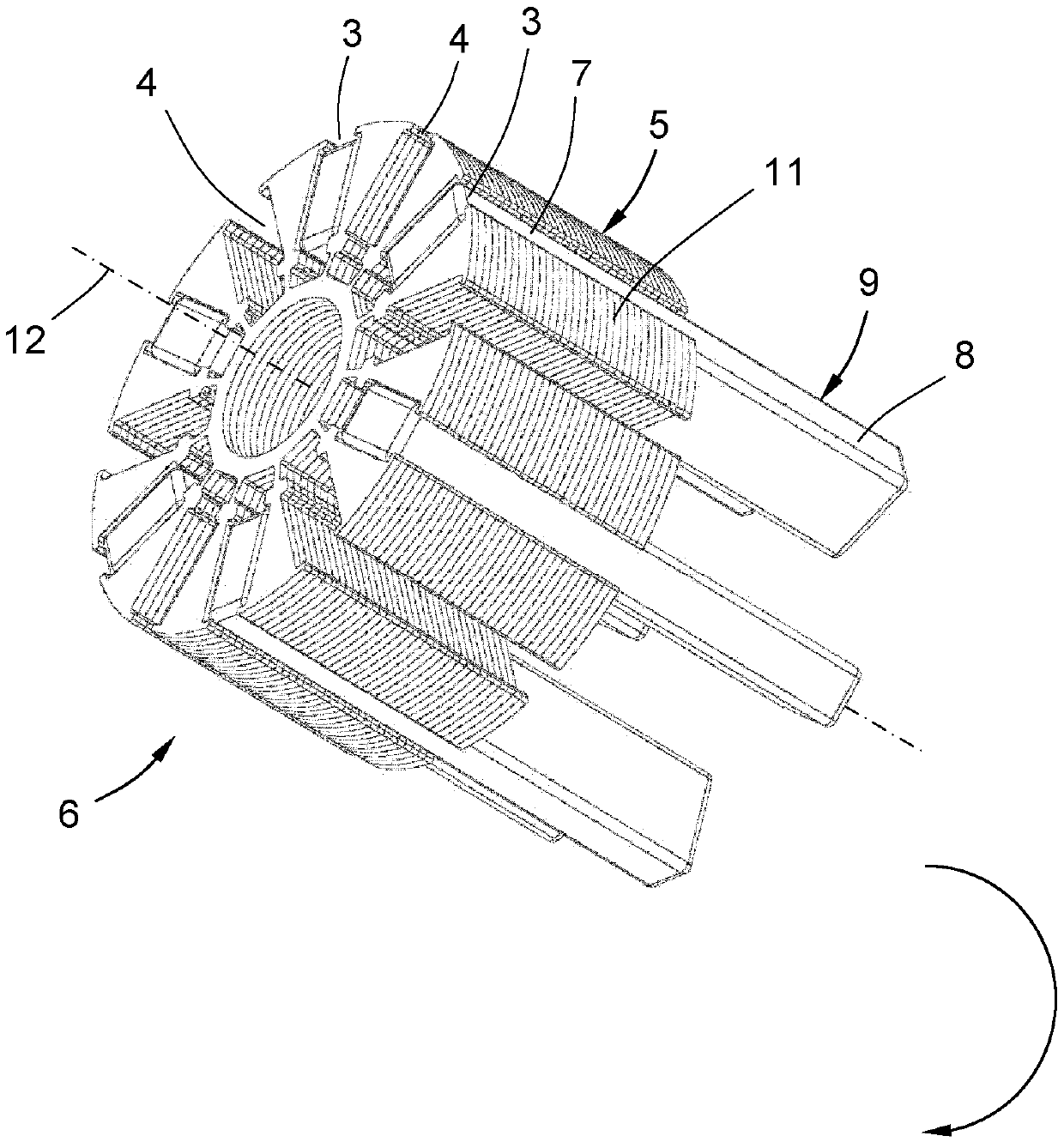

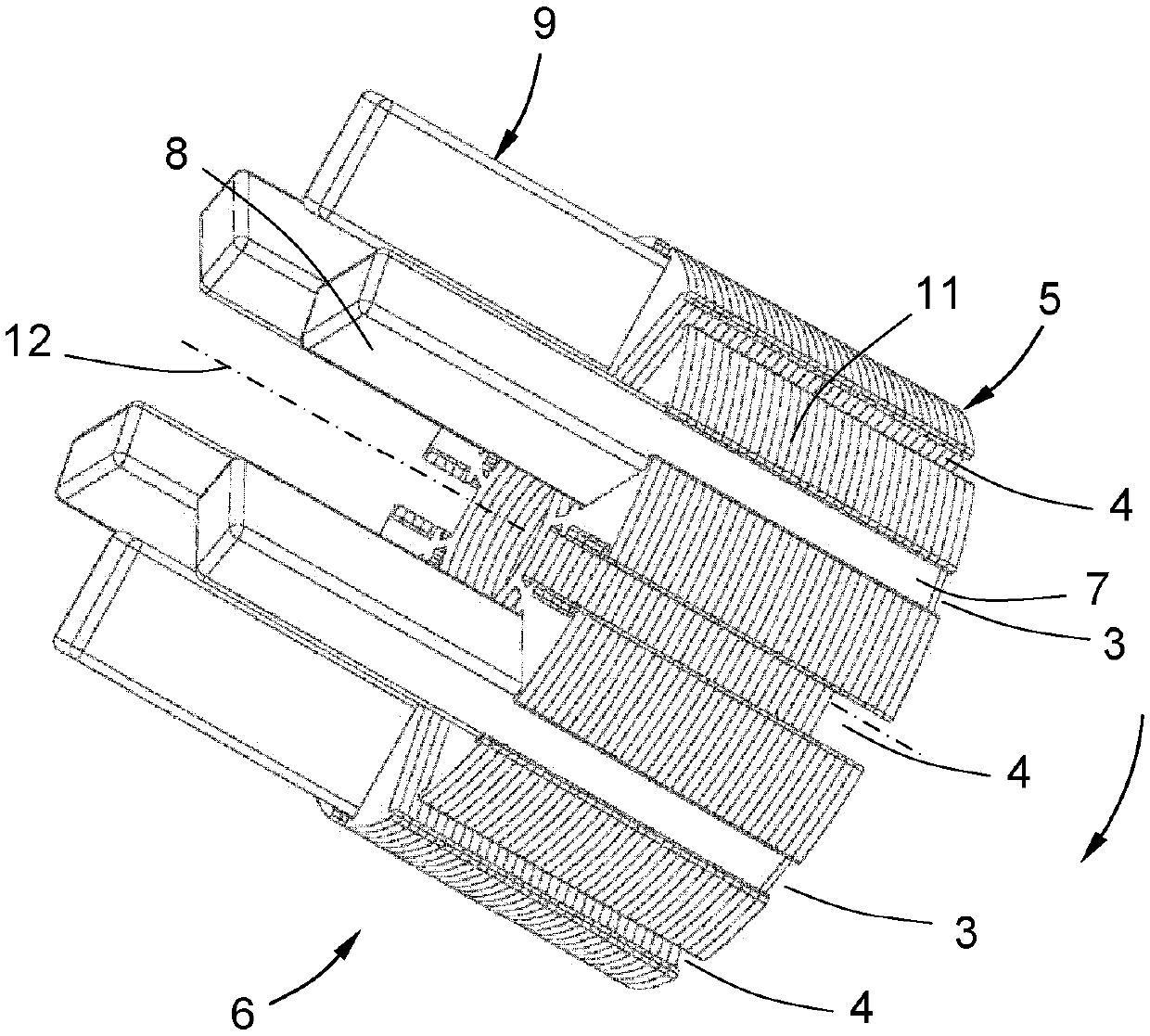

[0051] figure 1 A permanent magnet rotor 1 is shown (without rotor shaft) with a rotor axis of rotation 12 , a magnetic core 2 and permanent magnet blocks 9 mounted in magnet receptacles 3 , 4 . The magnetic core 2 is axially composed of two identical sub-cores 5 (see parting line 29 ). The permanent magnet blocks 9 are each accommodated with a first partial section 7 in the magnet receptacle 3 of one partial core 5 and with a second partial section 8 in the magnet receptacle 4 of the second partial core 5 . The first partial section 7 is mounted with an interference fit in every other magnet receptacle 3 of the two partial cores 5 and with a clearance or transition fit in the remaining magnet receptacles 4 . Each sub-core 5 and a plurality of permanent magnet blocks 9 form a rotor structural assembly 6 . exist figure 1 Twelve permanent magnet blocks 9 are shown in , wherein six permanent magnet blocks and sub-cores 5 form a rotor structure assembly 6 respectively. Two rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com