Permanent magnetism body system for rotary magnetic refrigeration

A technology of permanent magnets and magnets, applied in the field of permanent magnet magnet systems, can solve the problem that the circumferential dimension of the magnetic working fluid area cannot exceed 45 degrees, the circumferential dimension of the magnetic pole piece cannot exceed 45 degrees, and the heat exchange system of the magnetic refrigerator is complex, etc. problem, to achieve the effect of simple magnetic working medium processing and heat insulation, light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

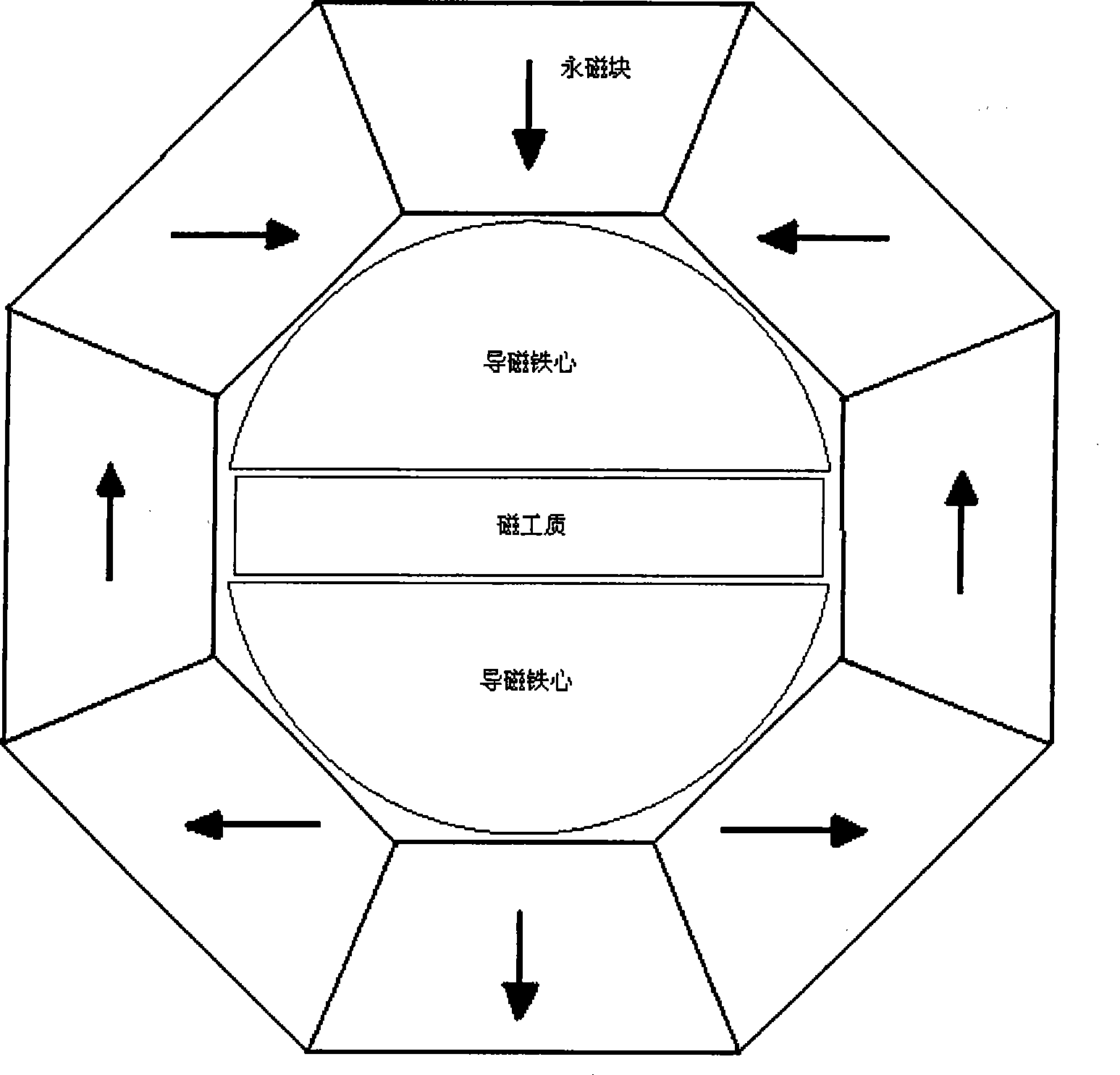

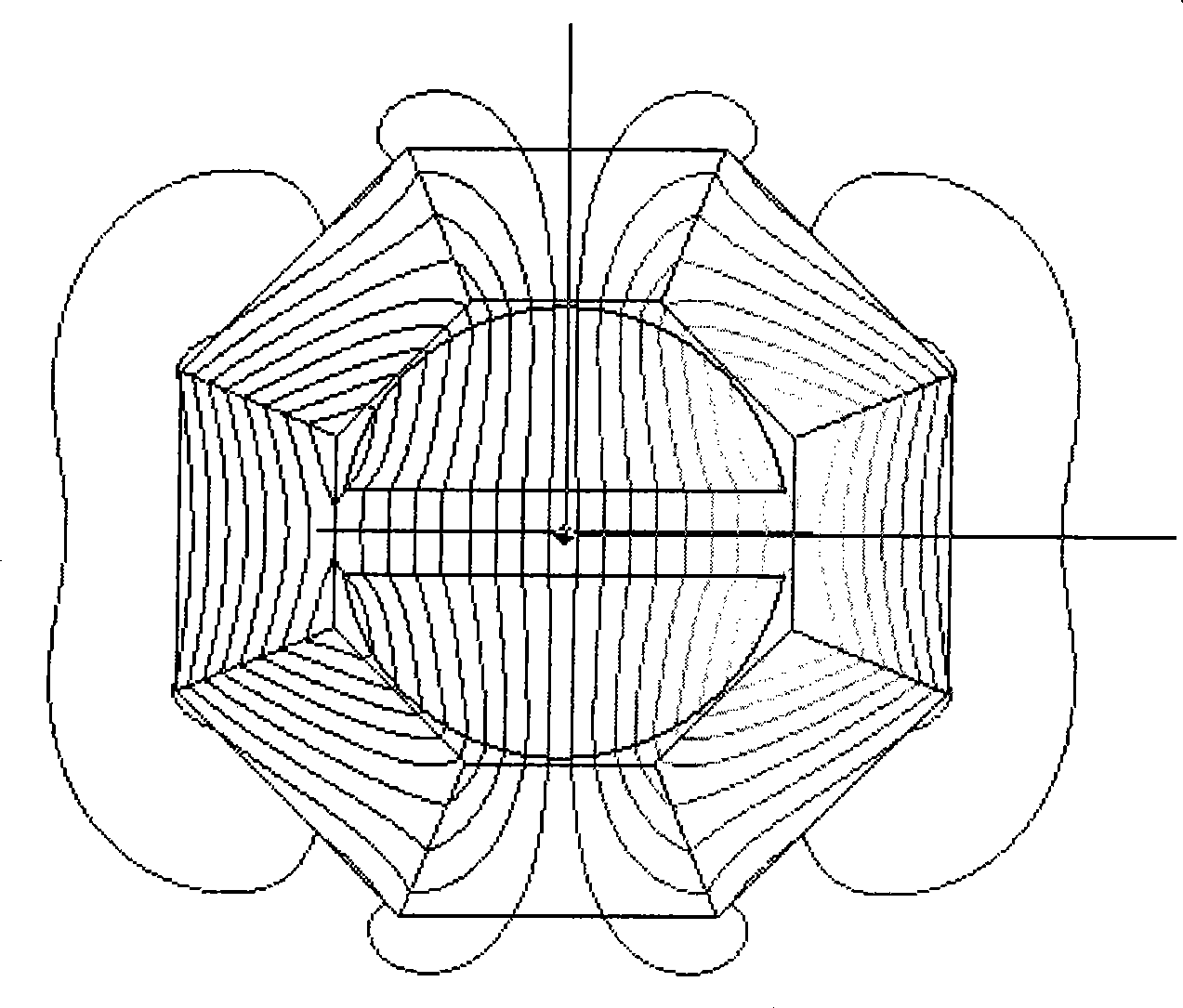

[0023] like figure 1 As shown, the Halbach hollow cylindrical permanent magnet of the stator is composed of 8 trapezoidal permanent magnets, and its magnetization direction is determined by the Halbach rotation theorem, as figure 1 indicated by the middle arrow. The permanent magnetic potential along the magnetization direction of the permanent magnet generates a bipolar magnetic field in the cavity of the hollow cylinder.

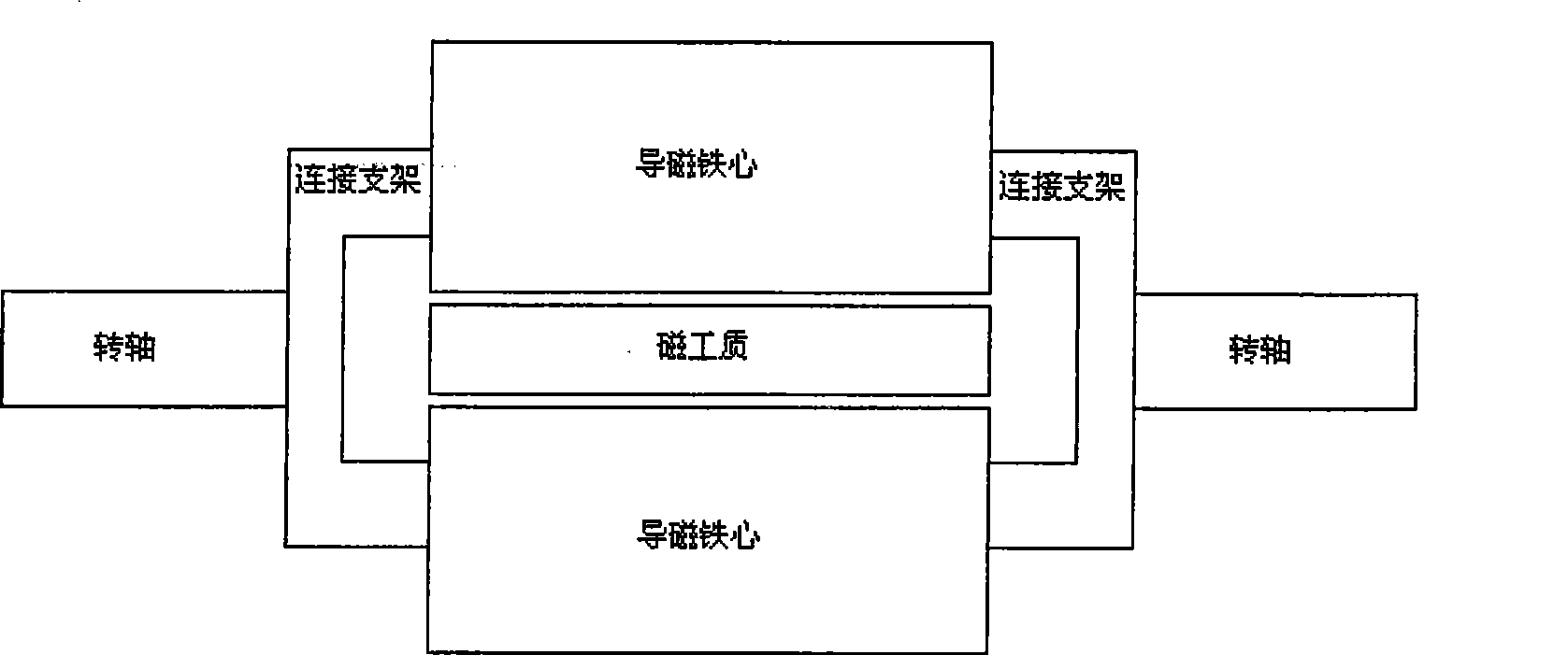

[0024] The shaft of the rotor is located at the rotation center of the rotor, and the centerlines of the two rotor shafts coincide with the geometric centerline of the stator. The two magnetic cores of the rotor are bow-shaped cylindrical bodies in cross-section, which are connected to the shaft through the connecting bracket to form a one-piece set on the shaft, such as figure 2 shown. The curved side of the bow-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com