Excitation control method for dual-axis excitation turbogenerator

A technology of turbo-generator and biaxial excitation, which is applied in the direction of synchronous generator control and generator control through magnetic field changes, which can solve the problem of the reduction of the ampere-turns of the excitation winding and the reduction of the synthetic excitation magnetomotive force, which limits the stable operation of the generator Limits, unfavorable power system stability and other issues, to achieve the effect of increasing the degree of freedom, realizing the same frequency and asynchronous operation, and reducing the system oscillation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

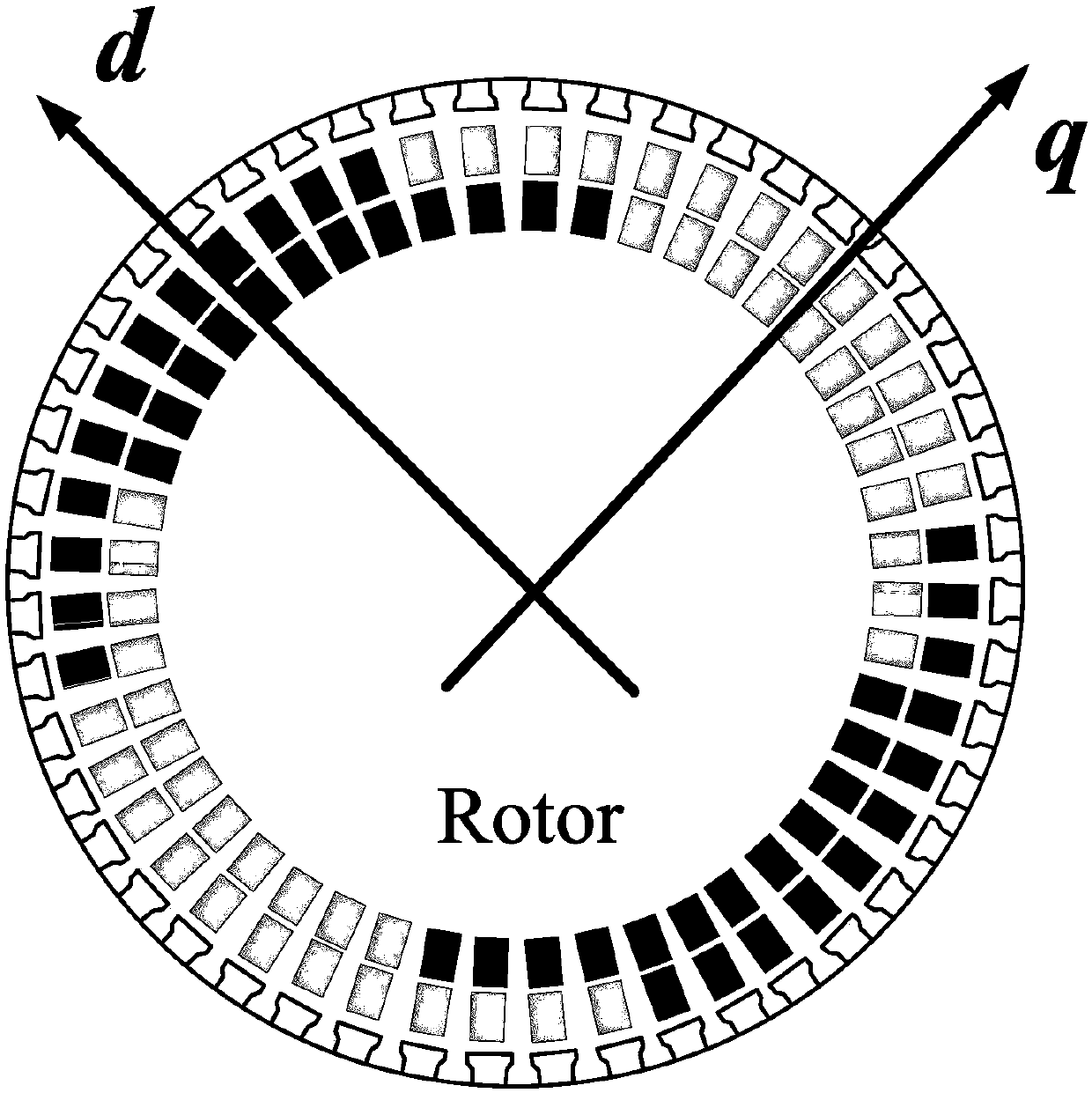

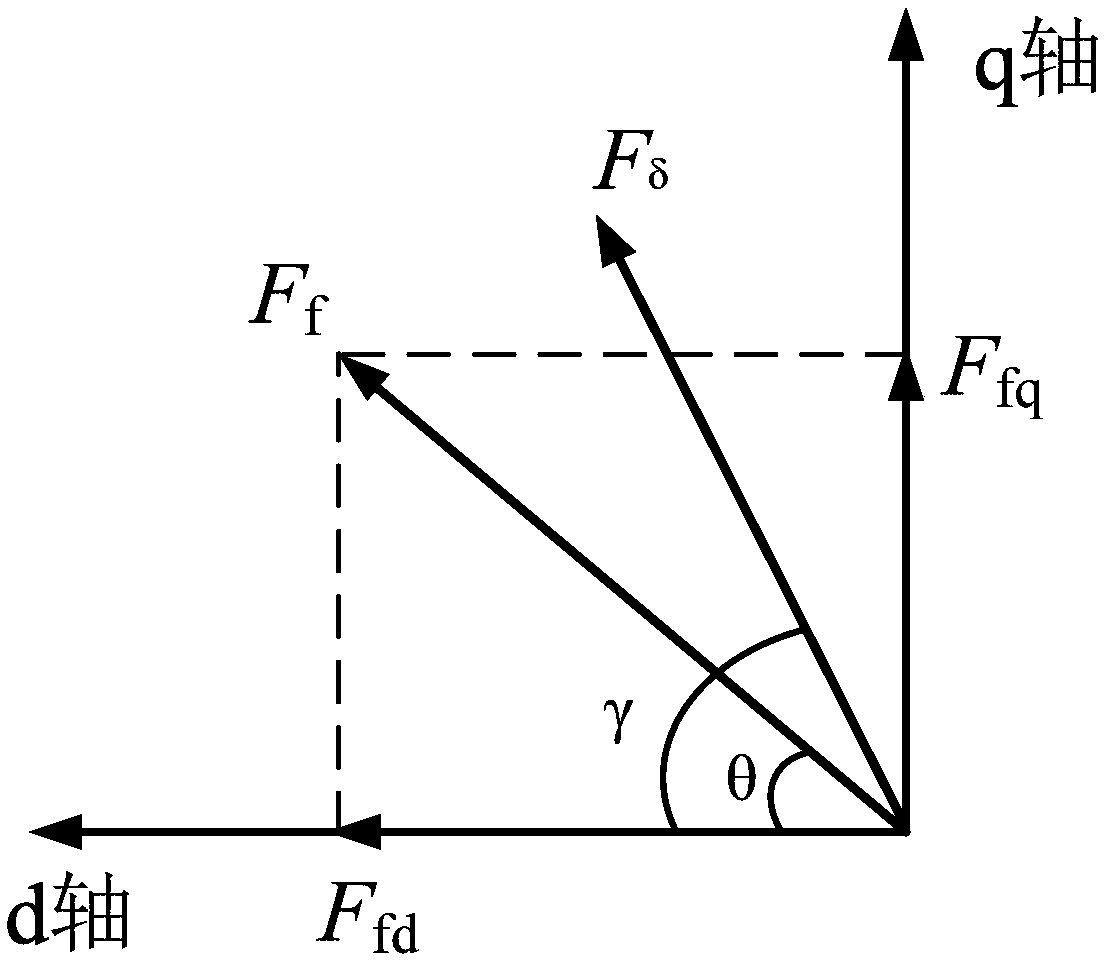

[0036] According to the technical scheme of the present invention, a 300MW biaxial excitation turbogenerator has been designed, the rotor cross section of this generator is as follows figure 1 As shown, the rotor is a two-pole hidden pole structure, and the two sets of windings on the rotor are perpendicular to each other in space; when the uniaxial excitation is applied, the d-axis excitation winding is fed with DC current, and the q-axis excitation winding is open; direct current respectively. A vector diagram of a magnetic field such as figure 2 shown.

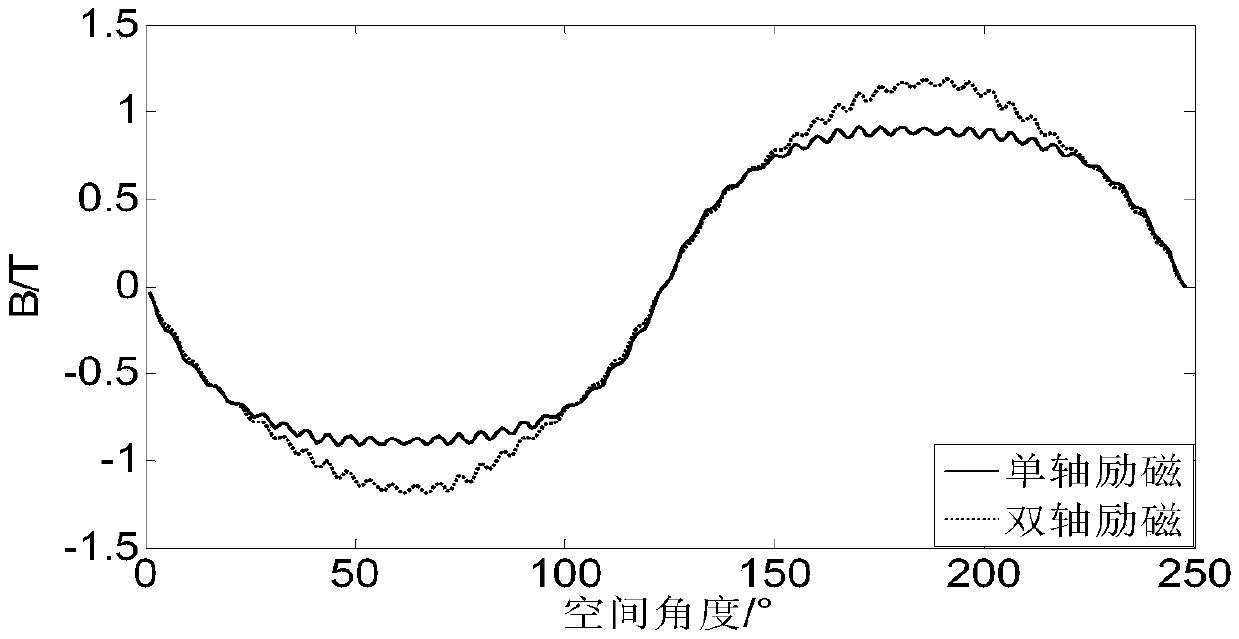

[0037] When the dual-shaft excitation turbogenerator has only one set of excitation windings to apply no-load excitation current, the air-gap flux density waveform and the air-gap flux density fundamental wave component when the iron core is saturated are ignored, such as image 3 As shown, the amplitude of the air-gap magnetic base wave is 0.8944T. When the two sets of excitation windings of the dual-shaft excitation t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com