A Closed Near Net Shaping Technology and Die for Final Forging of Drum Steering Knuckle

A near-net-shaping and steering knuckle technology, applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problem of high flash metal loss, reduce the forming force of die forging, simplify the structure, and shorten the operation the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

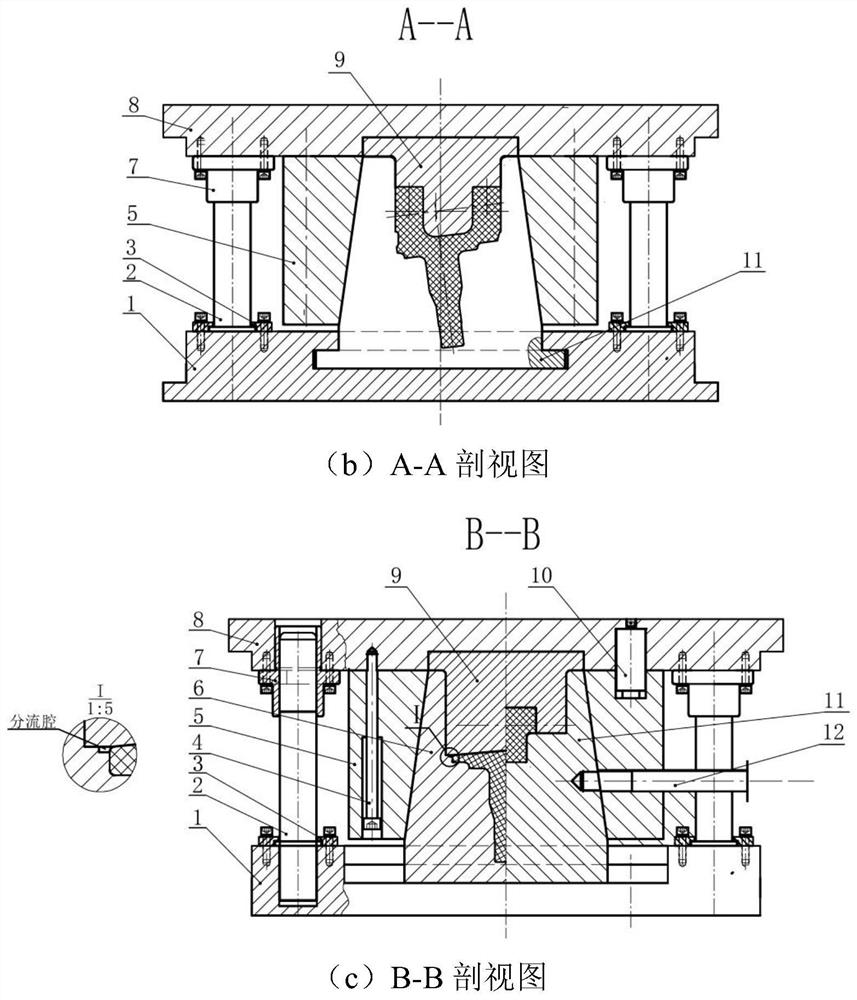

[0014] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

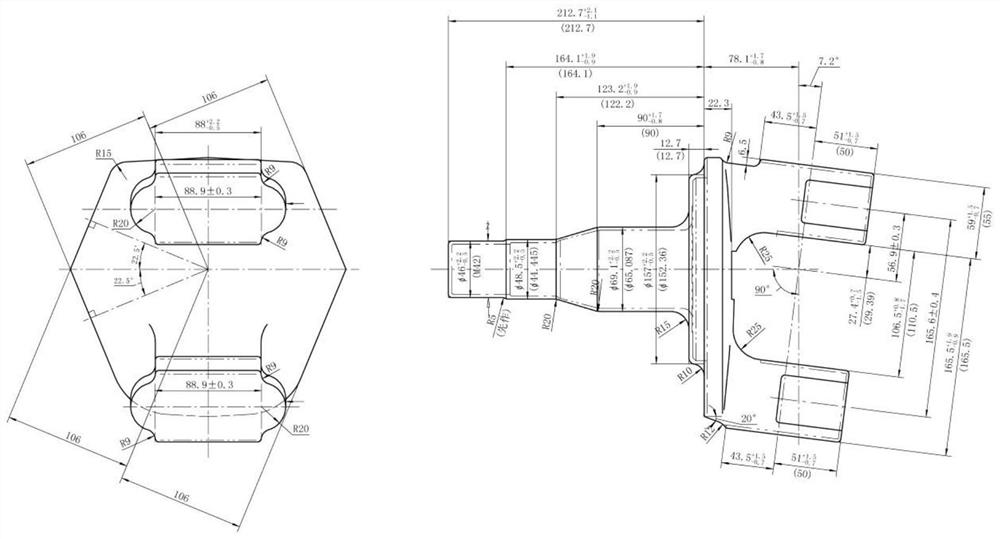

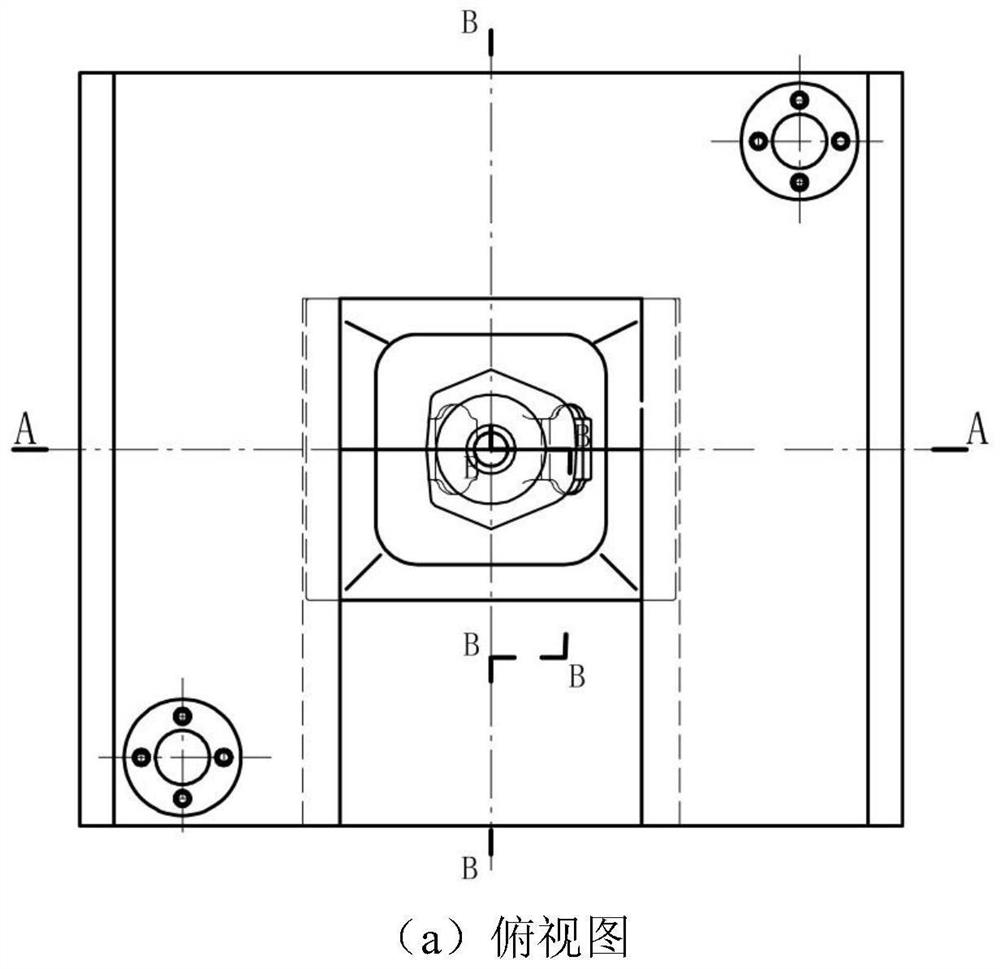

[0015] The A90 automobile steering knuckle, which has a large demand in domestic and foreign markets in recent years, is selected as an application example of this new process and mold. In order to adapt to the near-net shape of the closed final forging, the head of the pre-forging is designed as a flat fork-shaped structure. The cross-section of the fork ear is determined according to the cross-sectional shape and size of the lower section of the forging ear. The shape is rectangular, 87mm long, 58mm wide, and the fork ear Height according to final forging drawing ( figure 1 ) is determined, the height of the largest fork ear is 135mm, and the height of the smallest fork ear is 113.5mm; the horizontal projection shape of the flange is the same as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com