Radial tire curing bladder production technology

A technology of vulcanization bladder and production process, applied in the field of tire production, can solve the problems of long vulcanization time of vulcanization bladder, non-compliance with clean energy policies, damage to double bonds of polymer chains, etc., so as to shorten production operation time, improve market prospects, improve The effect of aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The invention is described in detail below in conjunction with the examples:

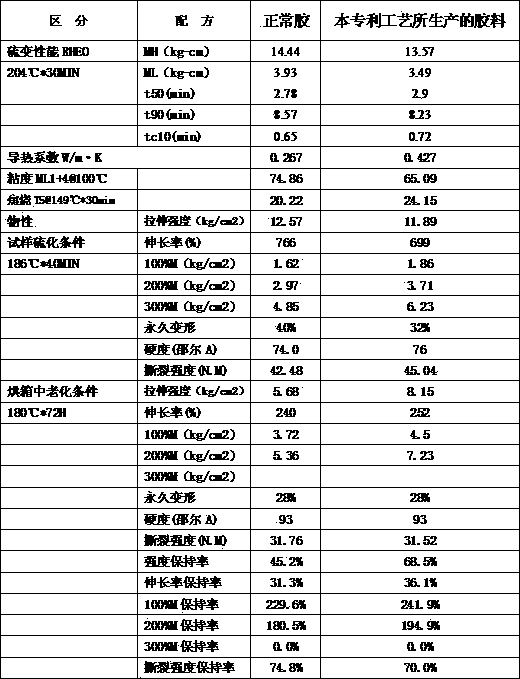

[0014] The present invention improves the existing production process by providing a production process for radial tire vulcanization bladders, adds glue and coumarone resin in the production process, and precisely controls the mold closing time of the mold, thereby greatly improving the production process. The vulcanization temperature is lowered, and the vulcanization time is reduced.

[0015] As a kind of specific embodiment of the present invention, the present invention provides a kind of radial tire vulcanizing bladder production process, and specific working steps are as follows:

[0016] Step 1: According to the following formula butyl rubber: 100PHR, neoprene: 3-5PHR, N330: 10-20PHR, acetylene carbon black: 40-60PHR, graphite: 10-20PHR, AL2O3: 5-10PHR, castor oil: 5 -10PHR, stearic acid: 0.5-1.5PHR, ZNO: 5-10PHR, resin: 6-10PHR for batching, this patent uses acetylene carbon black, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com