Grinding and washing device for steel bar

A technology of washing device and steel bar, applied in grinding/polishing safety device, grinding machine, grinding feed motion, etc., can solve the problem of low processing efficiency of steel bar, and achieve outstanding practicability, simple design and convenient feeding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

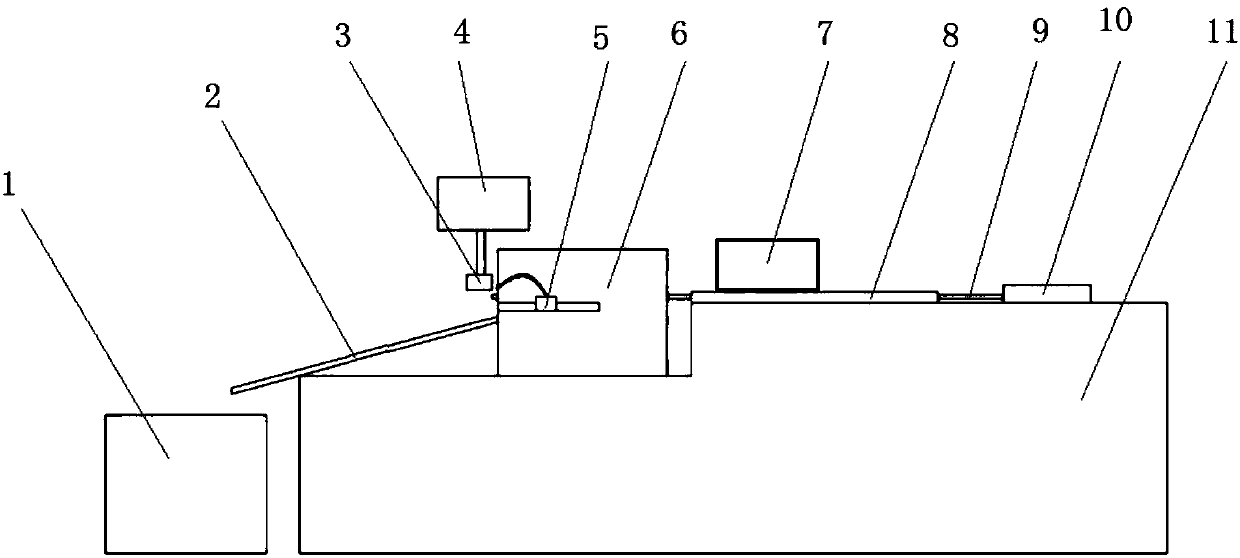

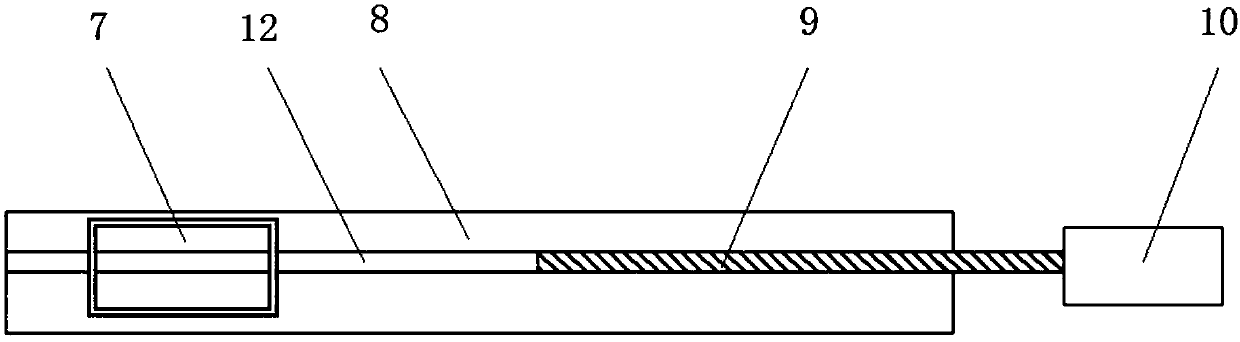

[0025] like figure 1 and figure 2 As shown, a steel bar grinding and washing device includes a pushing device, a clamping device 6, a grinding device, a washing device 5 and a receiving device, and the pushing device, the clamping device 6, the grinding device and the washing device 5 are arranged in sequence On the pedestal 11, the pedestal 11 is stepped, the pushing device is placed on the high-level step, the clamping device 6, the grinding device and the washing device 5 are placed on the same low-level step, and the pushing device is composed of a working platform 8, a cylinder 10 and The telescopic rod 9 is composed of a steel bar chute 12 arranged on the worktable 8, the telescopic rod 9 of the cylinder 10 and the steel bar to be processed are all placed in the steel bar chute 12, and the steel bar to be processed enters the steel bar from the feed port 7. After the bar chute 12, it is pushed into the clamping device 6 by the end of the telescopic rod 9 for grinding a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com