Novel CLT (Cross-laminated Timber) board adopting saw-tooth-shaped interlaminar gluing manner

A zigzag, new technology, applied in the direction of layered products, wood layered products, wooden veneer joints, etc., can solve the problems of easy aging, uneconomical, complex gluing process and design process, etc., to improve the overall The effects of stability, increased firmness, gluing process and simplicity of the design process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

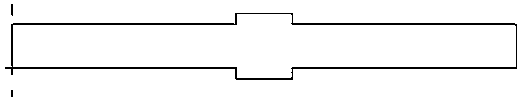

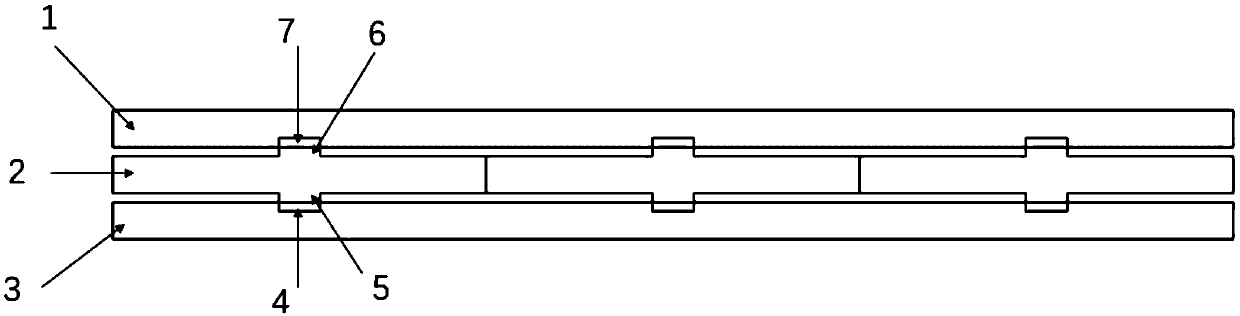

[0025] Such as figure 1 As shown, a new type of CLT board with zigzag interlayer glued method is a CLT member made of three-layer wood-gauge lumber glued together, including a layer of upper layer 1, a layer of lower layer 3 and a layer of core layer 2 . The core board 2 is made of poplar, a fast-growing wood, and the upper board 1 and the lower board 3 are made of hemlock, and are glued orthogonally with the core board 2 to form a CLT board.

[0026] Among them, such as image 3 As shown, the upper surface of the core board 2 is provided with several convex grooves 1 6 , and the lower surface is provided with several convex grooves 2 5 .

[0027] Such as Figure 5 As shown, the lower surface of the upper laminate 1 is provided with a groove 1 7 that can be matched and fitted with the convex groove 1 6, and the upper surface of the lower laminate 3 is provided with a groove 2 4 that can be matched and fitted with the convex groove 2 5 .

[0028] The concave and convex gro...

Embodiment 2

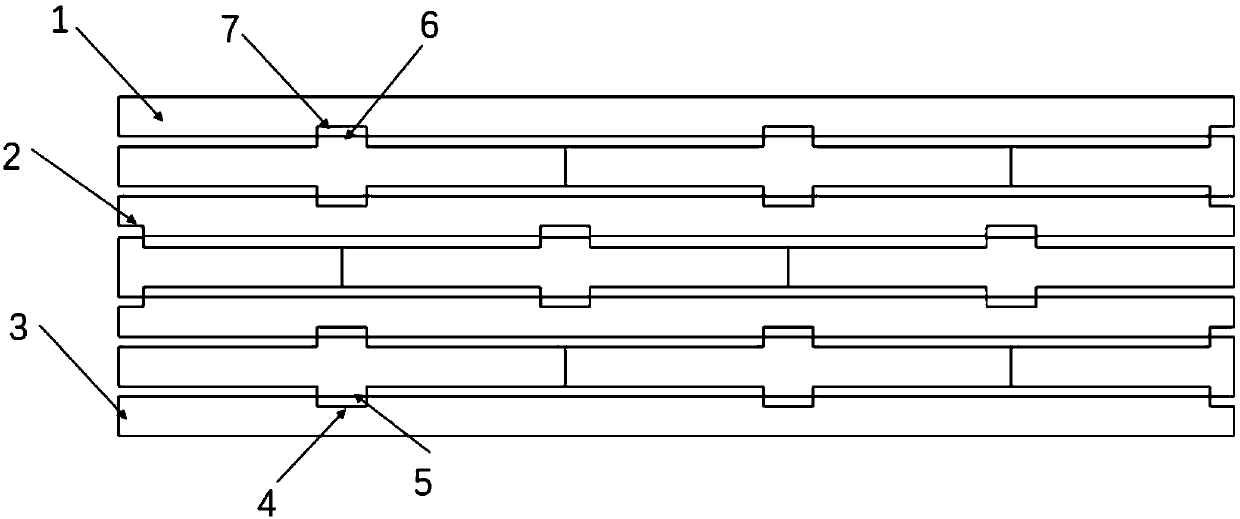

[0031] Such as figure 2 As shown, a new type of CLT board with zigzag interlayer glued method is a CLT member made of five layers of wood-gauge lumber glued together, including one upper layer 1, one lower layer 3 and three core layers 2 . The core layer board 2 is made of poplar, a fast-growing wood, and the upper layer board 1 and the lower layer board 3 are made of hemlock.

[0032] Among them, such as image 3 As shown, the upper surface of the uppermost core board 2 is provided with several convex grooves 1 6 , and the lower surface of the lowermost core board 2 is provided with several convex grooves 2 5 .

[0033] And the adjacent layer core boards 2 are still combined together with the concave-convex groove structure, the upper and lower surfaces of a certain layer of core boards 2 are convex grooves, and the upper and lower surfaces of the adjacent core boards 2 are grooves, such as Figure 4 As shown, the upper or lower surface of a certain layer of core board 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com