Stable widened stacker

A stacker, a stable technology, applied in the field of stacker, can solve the problems of small range of picking and placing materials, weak capacity of carrying heavy objects, poor balance, etc., to achieve improved stroke adjustment range, compact structure, large The effect of stroke range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

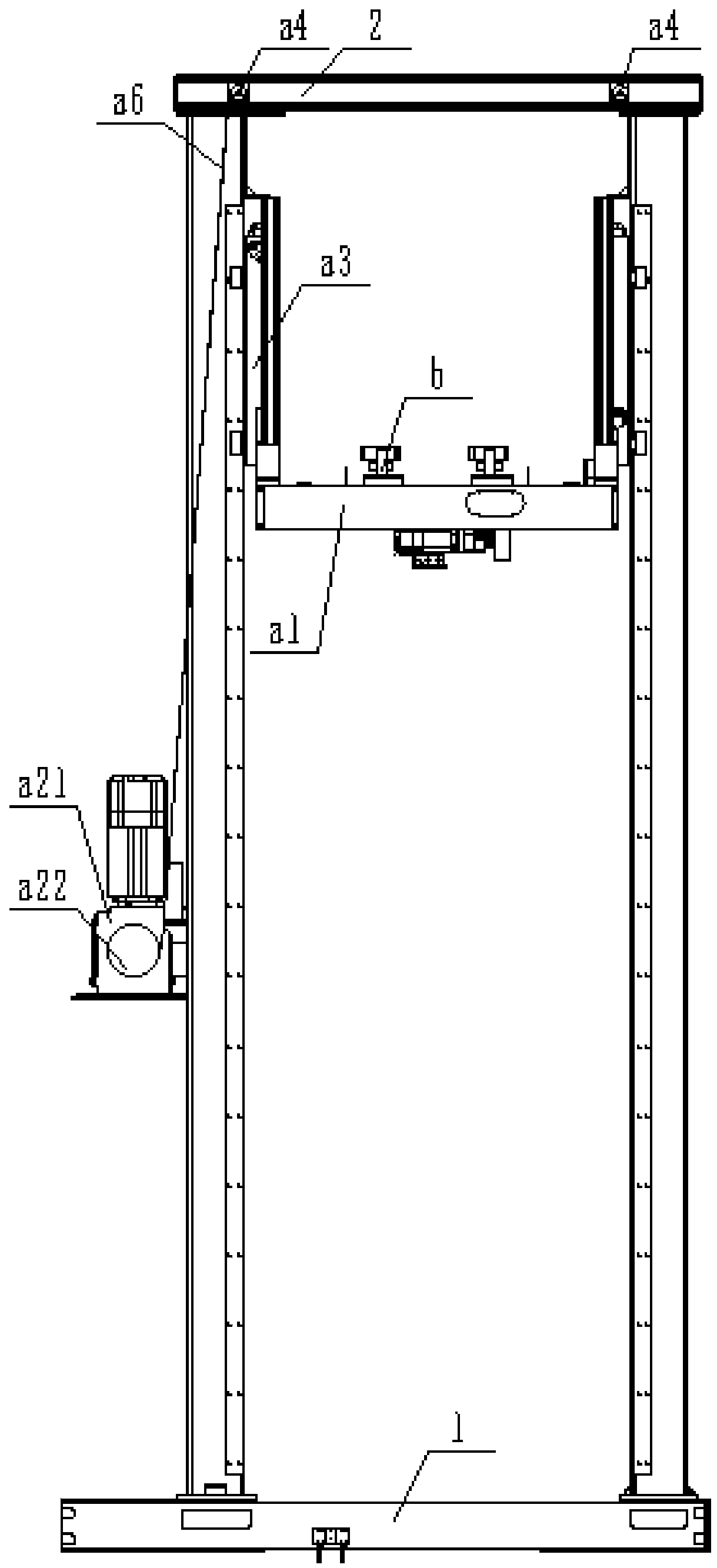

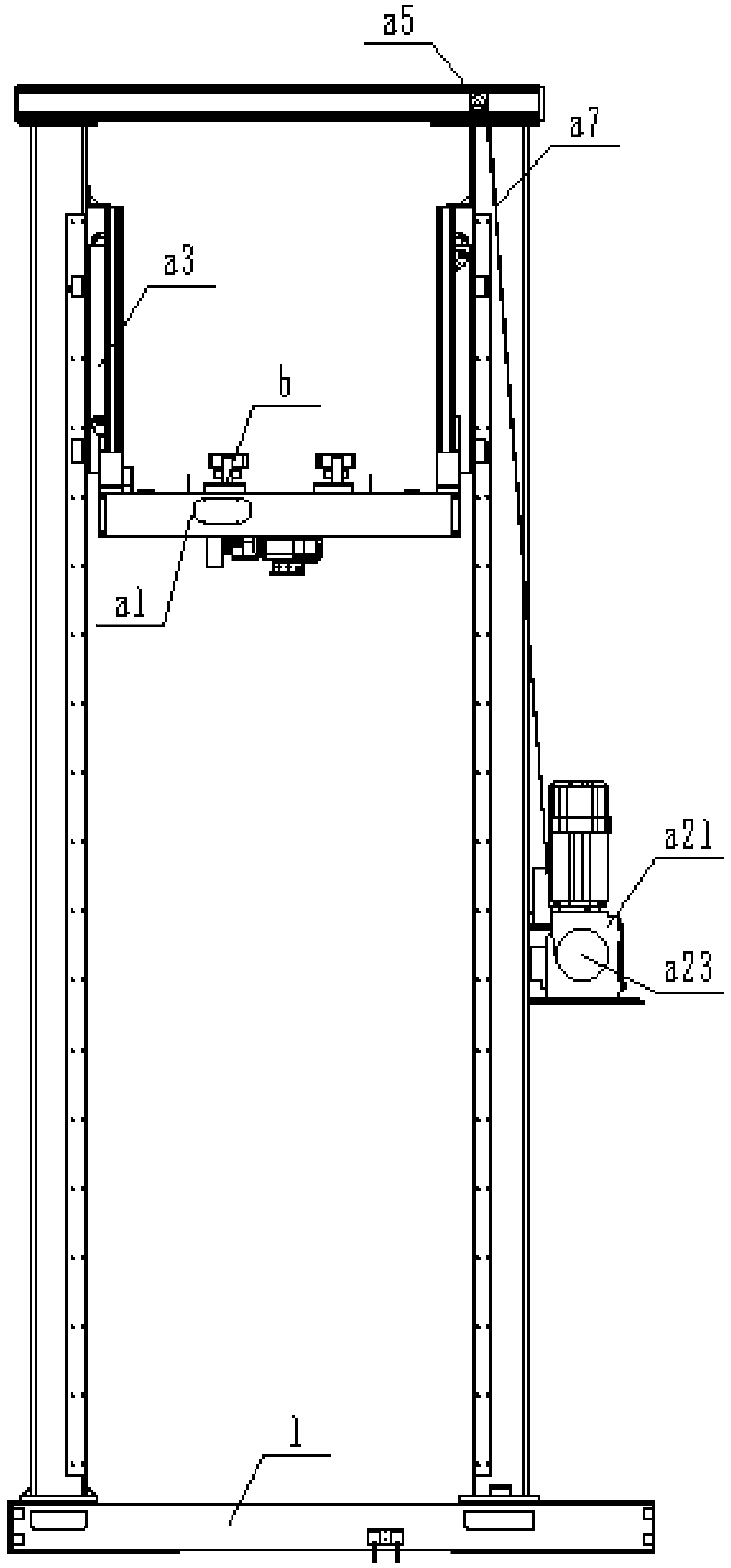

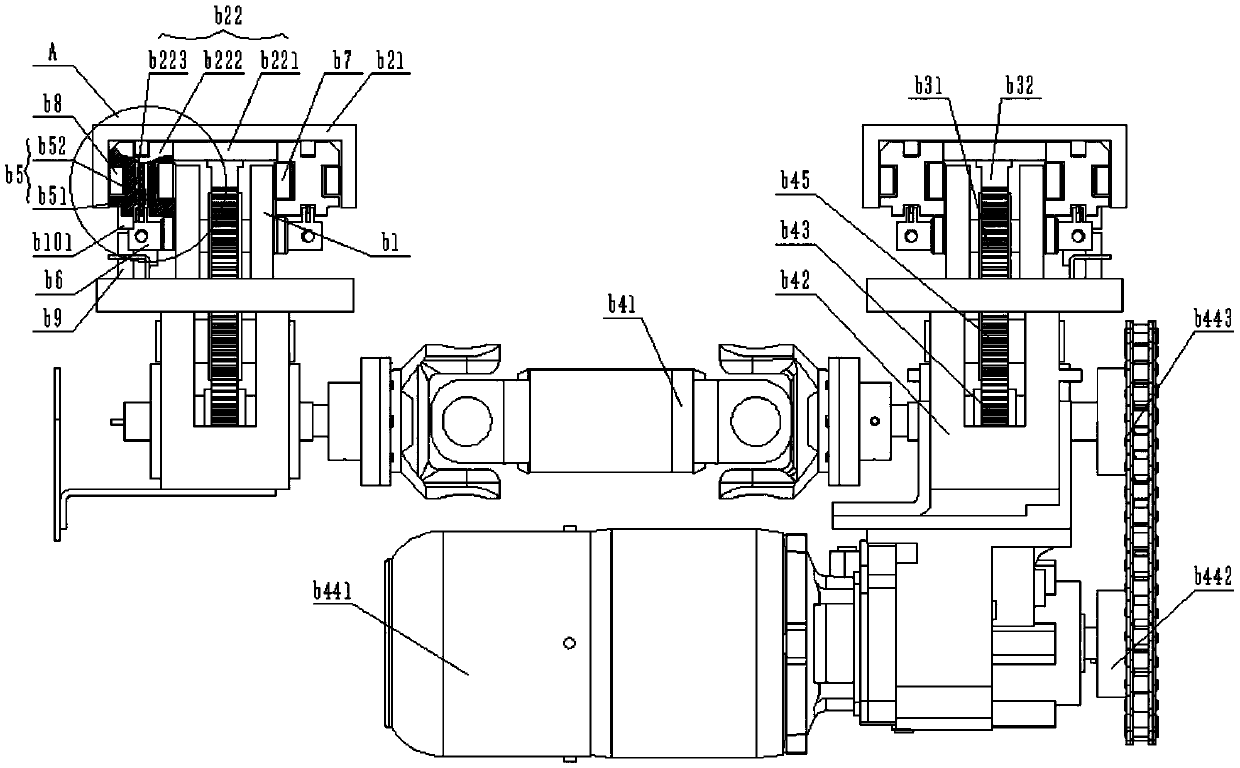

[0037] like Figure 1-8 As shown, a widened and stable stacker includes a base 1, on which a gantry 2 is vertically arranged, and a lifting device a is installed on the gantry 2, and a movable The telescopic fork b, the lifting device a drives the telescopic fork b to move vertically along the height direction of the gantry 2; the telescopic fork b includes two horizontally arranged fork frames b1, and the two A synchronous transmission assembly b4 is provided between the fork frames b1, a fork body b2 is installed on the fork frame 1, a fork body transmission assembly b3 is provided in the fork frame 1, and the fork body b2 is transmitted through the fork body The component 3 is slidably connected with the fork b1; the fork b2 includes an upper fork b21 and a lower fork b22 facing up and down, the upper fork b21 is slidably connected with the lower fork b22, and is connected with the The lower surface of the lower fork b22 is fixedly connected with the driven rack b32, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com