Crane for water conservancy project construction

A technology of water conservancy projects and cranes, which is applied in the direction of cranes, etc., can solve the problems of time-consuming and labor-intensive leveling of the site, and achieve the effects of saving time and effort for support, preventing rollover, and shortening the preparation work in the early stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

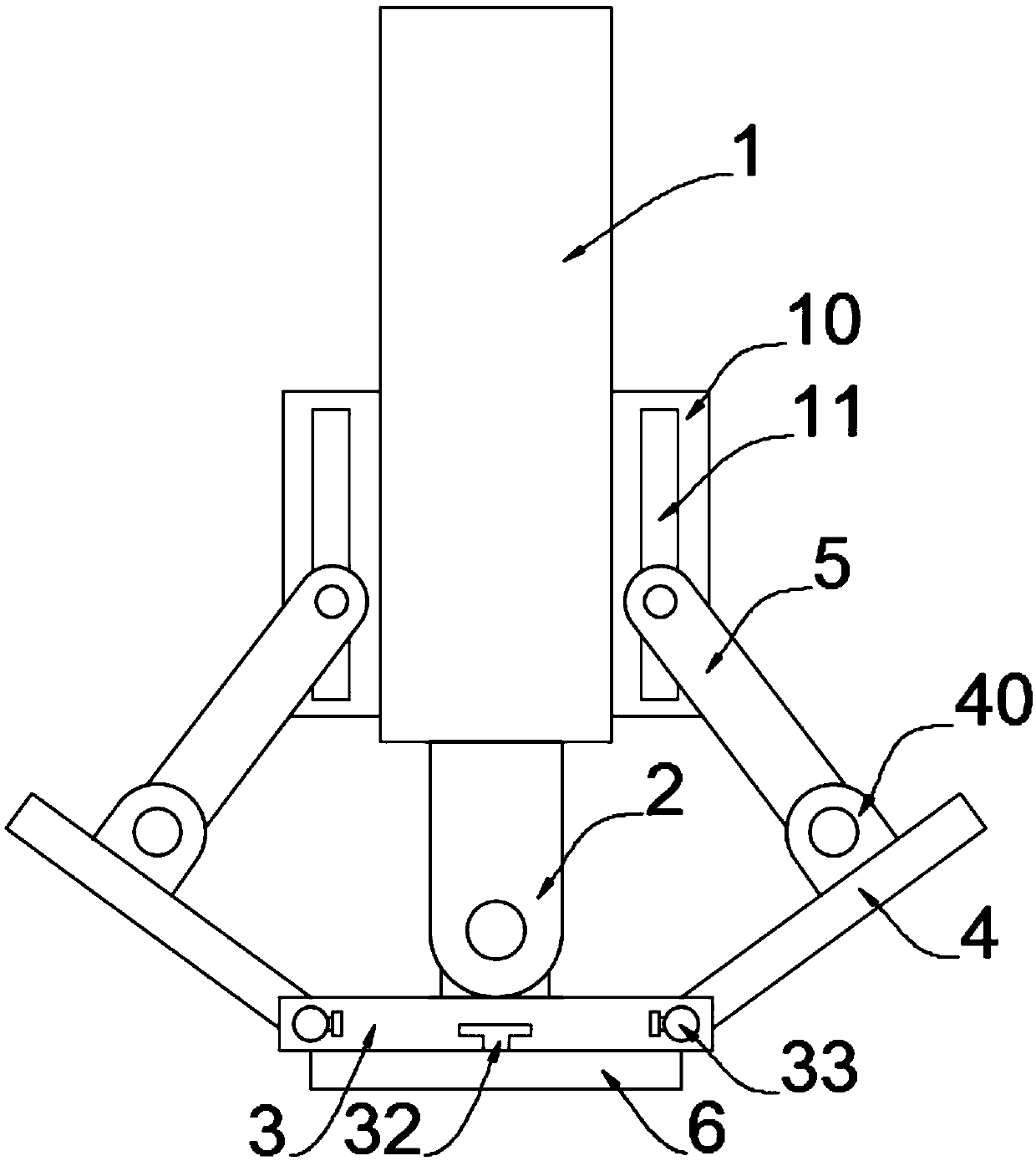

[0027] A crane for water conservancy construction, such as figure 1 As shown, it includes a cylinder 1, the lower end of the cylinder 1 is plugged with a cylinder 2, the lower end of the cylinder 2 is connected with a support plate 3, both sides of the support plate 3 are connected with side plates 4, and one side of the side plate 4 is connected There are connecting rods 5, and the bottom of the support plate 3 is provided with a backing plate 6.

[0028] In this embodiment, the cylinder 1 is a hydraulic cylinder with an inner diameter of 90 cm, an outer diameter of 112 cm, a wall thickness of 11 cm, and a weight of 27.4 kg / m.

[0029] Specifically, the supporting plate 3, the side plate 4, the connecting rod 5 and the backing plate 6 of this embodiment adopt medium-alloy medium-carbon secondary precipitation hardening ultra-high-strength steel, and the thickness is preferably 1 cm, so that it is strong enough to carry out Support work.

[0030] Further, both sides of the c...

Embodiment 2

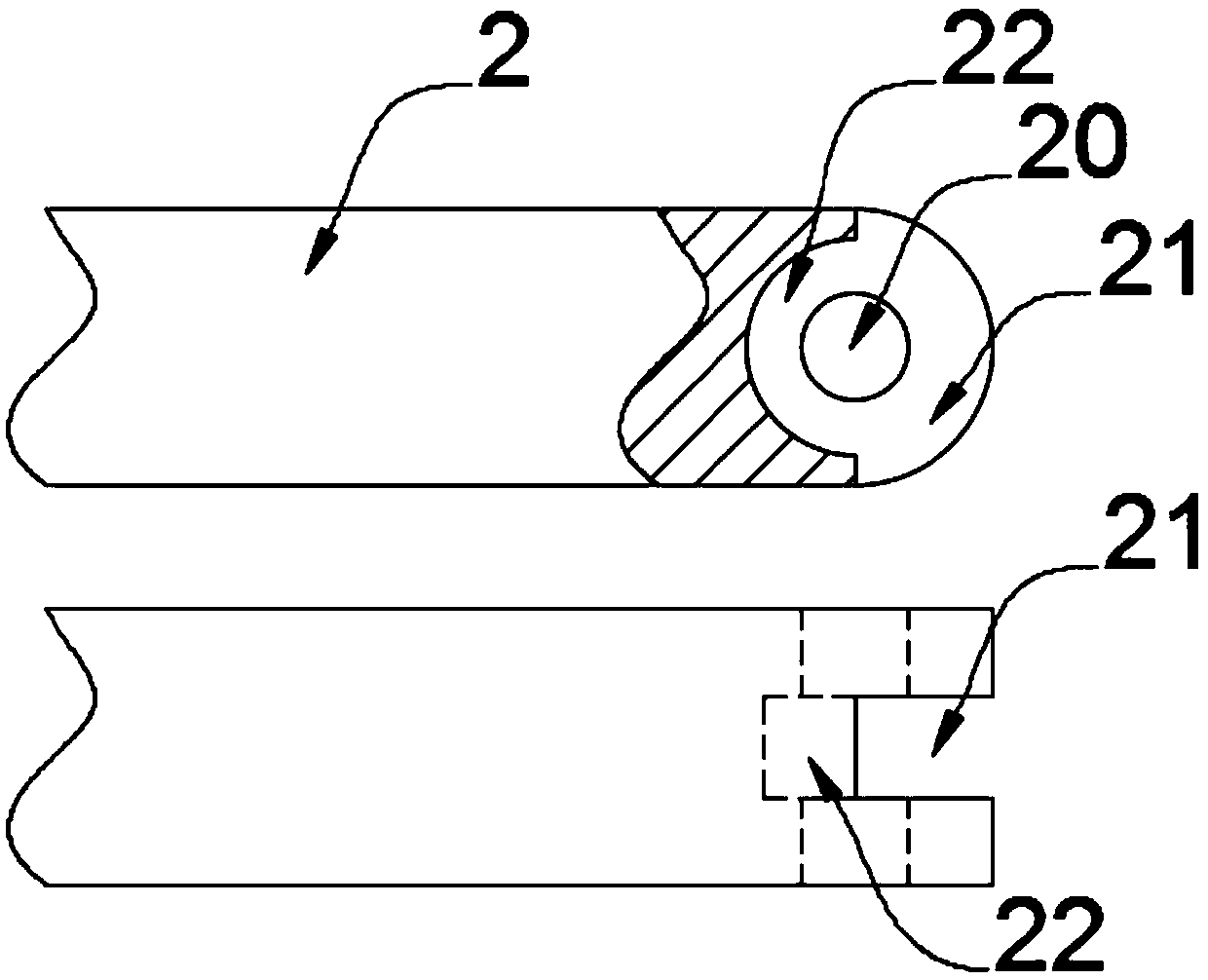

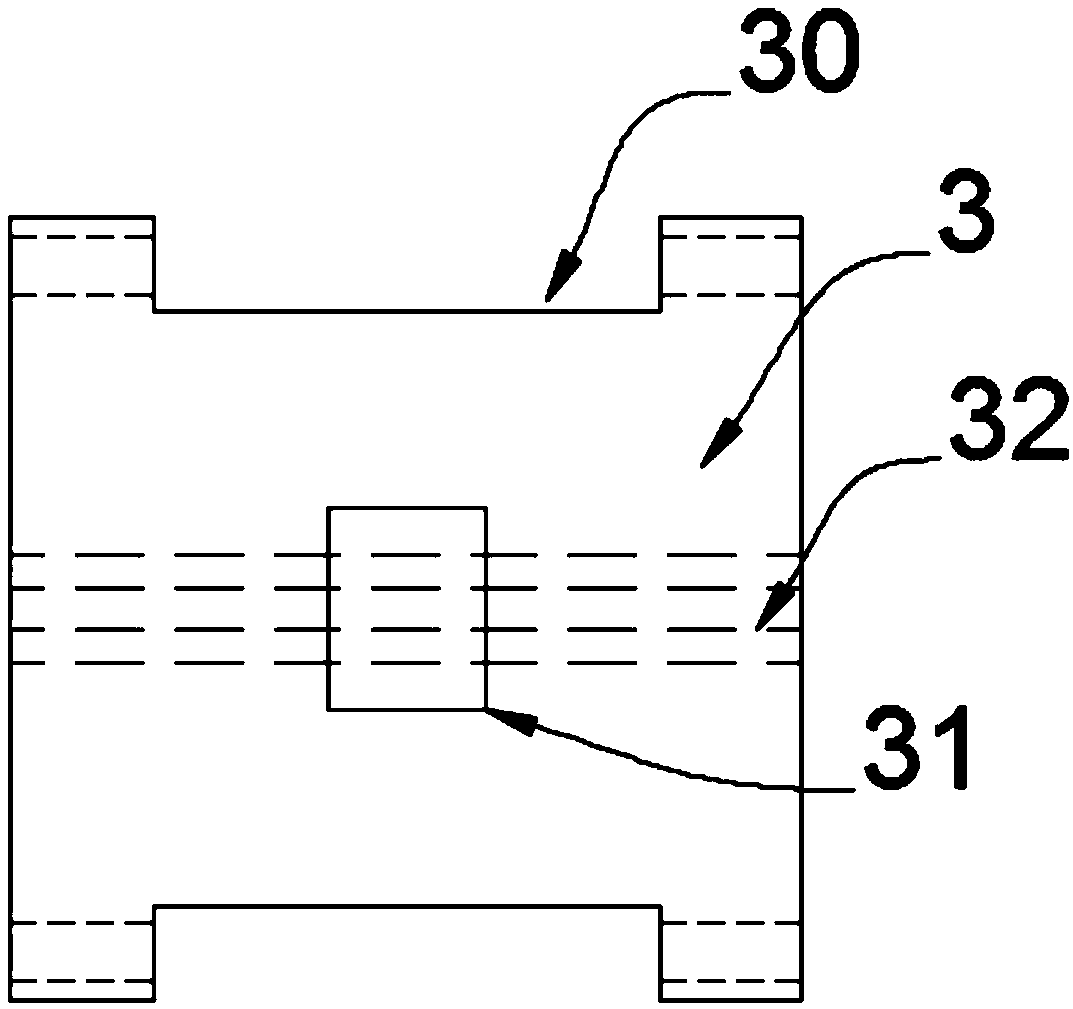

[0034] In the specific implementation, since a crane needs to be used in water conservancy construction, the crane needs hydraulic support legs to maintain balance and avoid rollover. The support plate 3 and the side plate 4 are improved, such as Figure 2-6 As shown, column holes 20 are provided on both sides of the bottom of the column body 2, a notch 21 is provided at the bottom of the column body 2, a semicircular groove 22 is provided on one side of the notch 21, and a connecting port 30 is provided at both ends of the support plate 3, The upper surface center of the support plate 3 is welded with a support block 31, one side of the support plate 3 and the lower surface are provided with a T-shaped groove 32, the upper surface of the side plate 4 is welded with a bump 40, and one side of the side plate 4 is provided with There are connection blocks 41 .

[0035] Specifically, the bottom end of the cylinder 2 is a spherical structure, and the semicircular groove 22 is hin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com