A joint injection molding type polypropylene geogrid and a preparation method thereof

A technology of geogrid and polypropylene, applied in soil protection, other household appliances, infrastructure engineering, etc., can solve the problems of unsatisfactory grid tension effect, maximum 50k, strip performance damage, etc. Achieve the effect of high overall tensile strength, high strength and good forming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

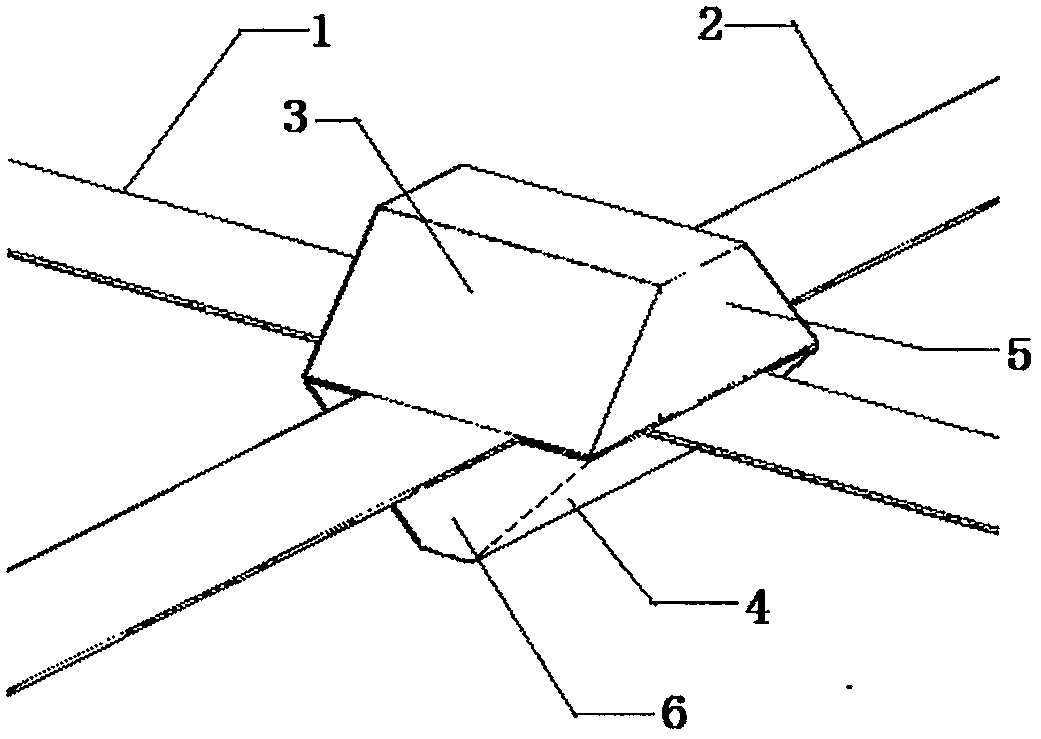

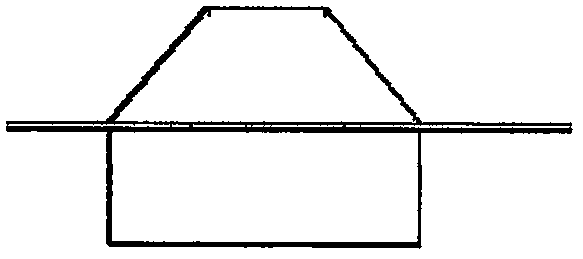

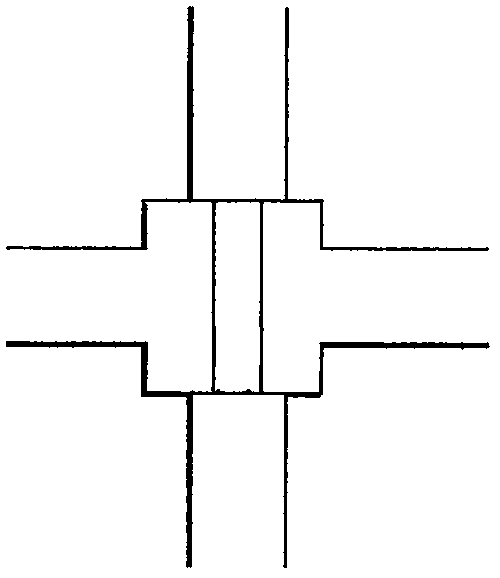

[0028] Such as Figure 1-3 As shown, a connection point injection-molded polypropylene geogrid includes a transverse strip 1 and a longitudinal strip 2, and the transverse strip 1 and the longitudinal strip 2 are polypropylene strips, and cross to form a grid , the position where the transverse strip and the longitudinal strip intersect forms a node, and the node is provided with an integrally injection-molded polyethylene reinforcing block 3, and the node is located at the center of the reinforcing block 3, and the reinforcing block The left and right sides of the part located at the top of the node are provided with an upslope surface 4 with a slope of 30-50°, and the front and rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com