A device for eliminating transmission gear clearance in a gearbox

A transmission gear and gearbox technology, which is applied in the field of gear backlash elimination, can solve problems such as the influence of the positioning accuracy of the output end, high production costs of helical gears, and unstable anti-backlash conditions, so as to achieve universal transmission conditions, reduce operating costs, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

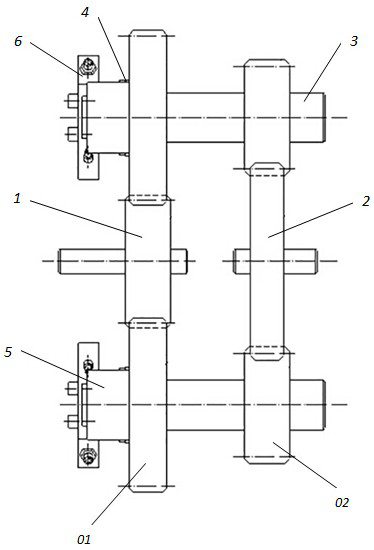

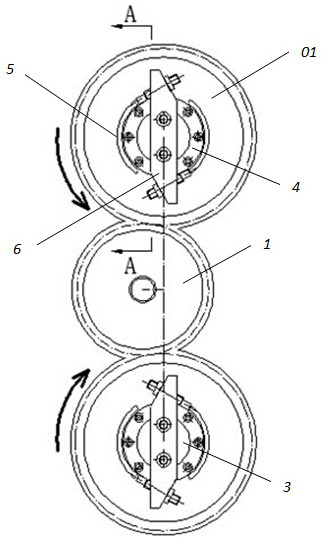

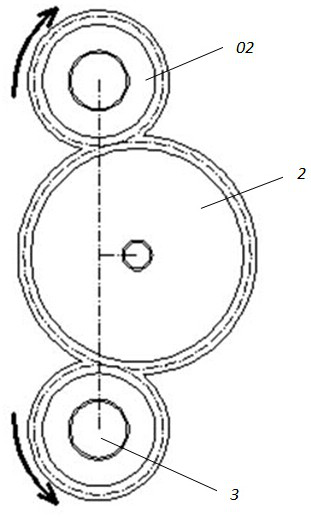

[0028] A device for eliminating transmission gear gaps in the gearbox in this embodiment, such as Figure 1-Figure 4 As shown, it includes the input gear 1 and the output gear 2, and also includes the anti-backlash shaft 3, the left end of the anti-backlash shaft 3 is set with the first anti-backlash gear 01 through the lock piece 4, and the right end of the anti-backlash shaft 3 is fixed The second anti-backlash gear 02 is sleeved; the input gear 1 meshes with two first anti-backlash gears 01 respectively, and the output gear 2 meshes with two second anti-backlash gears 02 respectively; the first anti-backlash An arc-shaped step 5 is arranged on the left end surface of the gear 01 , and an adjustment member 6 is installed on the left end of the anti-backlash shaft 3 .

[0029] Before gear transmission, it is necessary to pre-eliminate the transmission gap between the gear sets. First, loosen the locking member 4 and cancel the locking of the first anti-backlash gear 01. At th...

Embodiment 2

[0035] This embodiment is further optimized on the basis of embodiment 1, such as Figure 5 As shown, the adjustment member 6 includes an adjustment seat 61 and an adjustment bolt 62, the adjustment seat 61 is fixedly installed on the left end of the anti-backlash shaft 3, and the two ends of the adjustment seat 61 are installed with adjustment bolts 62 in reverse directions; The end surface of the adjusting bolt 62 is in contact with the side of the arc-shaped step 5 , and the axial direction of the adjusting bolt 62 is tangent to the circumference of the arc-shaped step 5 .

[0036] When it is necessary to eliminate the backlash, turn the adjusting bolt 62 installed at both ends of the adjusting seat 61, so that the end face of the adjusting bolt 62 pushes the side of the arc-shaped step 5, and the arc-shaped step 5 rotates in a circular direction under the push of the adjusting bolt 62, and manually By manipulating the screw-out or forward stroke of the adjusting bolt 62, t...

Embodiment 3

[0039] This embodiment is further optimized on the basis of the above-mentioned embodiment 1 or 2. The two ends of the adjustment seat 61 are provided with mutually parallel slopes, and the adjustment bolts 62 are installed through the slopes.

[0040] If the two ends of the adjustment seat 61 are not provided with mutually parallel slopes, in order to ensure that the axial direction of the adjustment bolt 62 is tangent to the circumference of the arc-shaped step 5, the mounting hole of the adjustment bolt 62 must be in a state close to the level, then the arc-shaped step 5 is just close to the shape of a semicircle, which causes the installation position of the adjustment bolt 62 to be very narrow this time, which is unfavorable for manual operation of the adjustment bolt 62. Therefore, in order to ensure that the axial direction of the adjusting bolt 62 is tangent to the circumference where the arc-shaped step 5 is located, the stroke space of the adjusting bolt 62 is as larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com