Garment molding method for pleating through sponge and shrink film shrinkage

A clothing modeling and shrink film technology, applied in the field of clothing modeling, can solve the problems of high cost and poor wrinkling effect of pleated clothing, and achieve the effects of protecting the characteristics of the fabric, vivid and rich pattern design, and good economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) The clothes are scaled according to the shrinkage ratio of 1:2 in the horizontal direction and 1:1.25 in the vertical direction, and the clothing pieces are obtained by cutting, and the clothing pieces are made of polyester imitation silk fabric;

[0038] (2) The computer designs the required embroidery pattern, and enlarges it in the same proportion according to the shrinkage of the fabric in step (1);

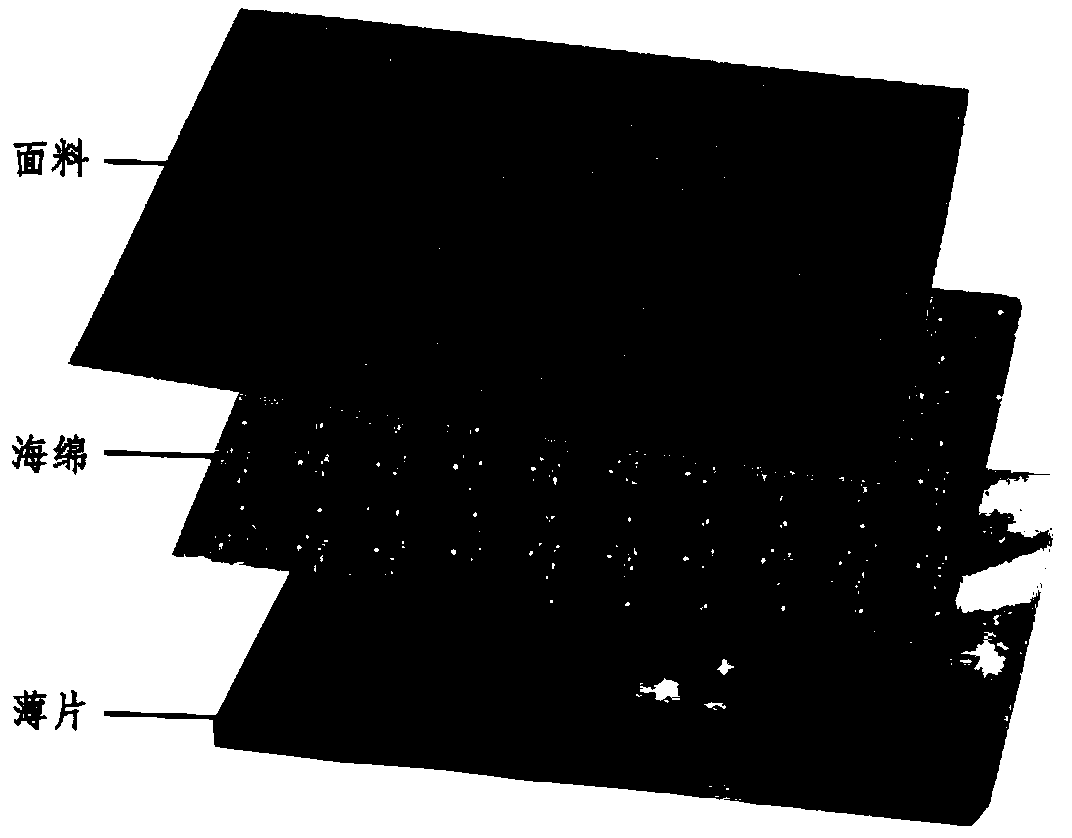

[0039] (3) Attach a layer of sponge and shrink film under the garment piece in step (1), the thickness of the selected sponge is 0.3mm, attach the three layers of garment piece, sponge and shrink film together, and carry out computer embroidery sewing, according to The pattern designed above;

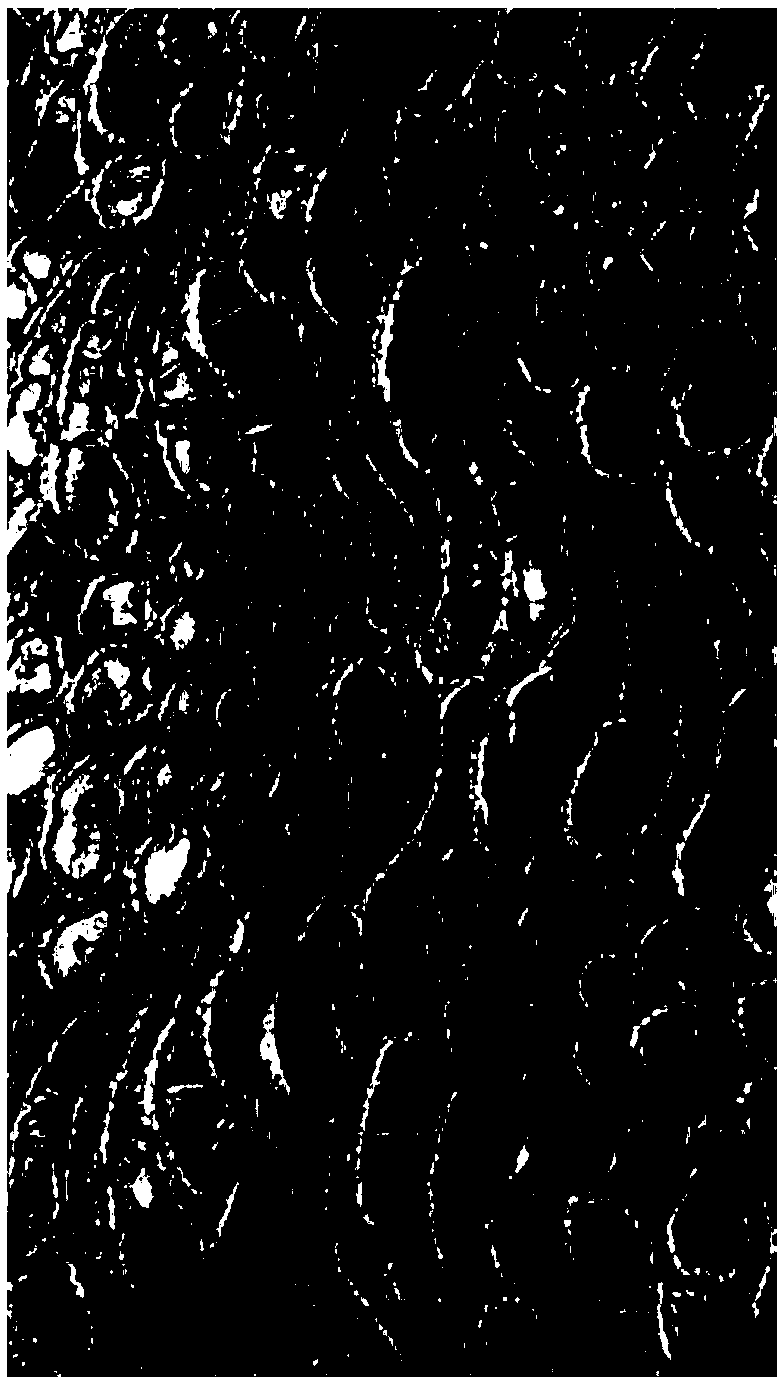

[0040] (4) Place the garment pieces sewn by computer in step (3) in an oven for high-temperature shrinkage, adjust the temperature of the oven to 150°C, and keep the temperature for 5 minutes, and use the property of the shrink film to shrink when heated to make the garment ...

Embodiment 2

[0045] (1) The clothes are scaled according to the shrinkage ratio of 1:2 in the horizontal direction and 1:1.25 in the vertical direction, and the clothing pieces are obtained by cutting, and the clothing pieces are made of polyester imitation silk fabric;

[0046] (2) The computer designs the required embroidery pattern, and enlarges it in the same proportion according to the shrinkage of the fabric in step (1);

[0047] (3) Attach a layer of sponge and shrink film under the garment piece in step (1), the thickness of the selected sponge is 0.3mm, attach the three layers of garment piece, sponge and shrink film together, and carry out computer embroidery sewing, according to The pattern designed above;

[0048] (4) Place the garment pieces sewn by computer in step (3) in an oven for high-temperature shrinkage, adjust the temperature of the oven to 150°C, and keep the temperature for 5 minutes, and use the property of the shrink film to shrink when heated to make the garment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com