Method for using secondary shield fastening device between 90-degree angle zone modules of Mark III type cargo tank

A fastening device and secondary shielding technology, which is applied in the field of liquid cargo tank construction of LNG ships, can solve problems such as uneven stress on the top position of the knuckle, unguaranteed pressure parameters, and unqualified construction quality, so as to ensure integrity and controllability , simple structure, and the effect of improving the quality of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

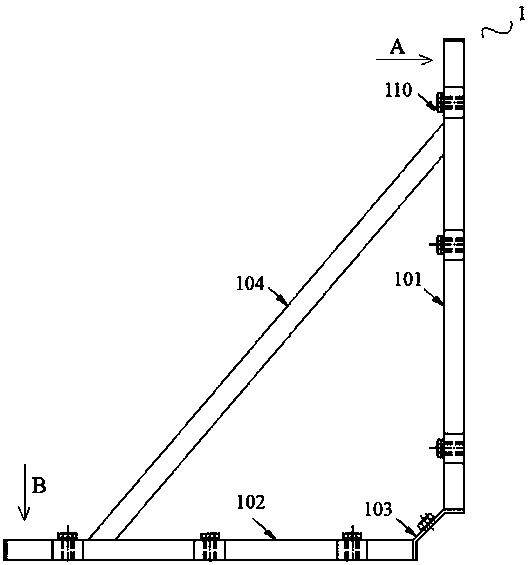

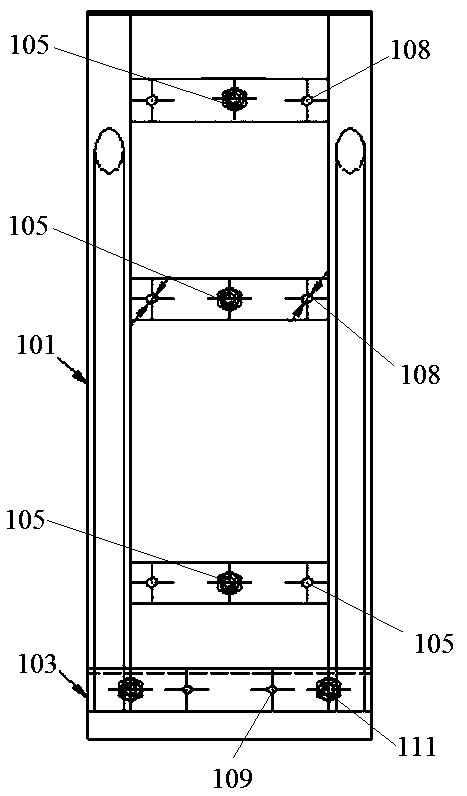

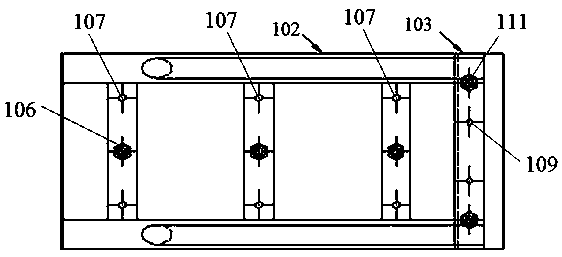

[0029] Such as Figure 1-Figure 13 As shown, the use method of the secondary shielding fastening device between modules in the 90° angle area of the Mark III liquid cargo tank in this embodiment, the device includes a fixed frame 1, a fixed bead 2, a plane pressing system 3 and a corner pressing system 4;

[0030] The fixed frame 1 includes a first plane frame 101 and a second plane frame 102, which are welded at 90° between the first plane frame 101 and the second plane frame 102, and the first plane frame 101 and the second plane frame The frames 102 are welded and connected by a turning plate 103, and a connecting rod 104 is provided between the first plane frame 101 and the second plane frame 102, and the first plane frame 101 and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com