Manual forklift with self-leveling function

A manual forklift and self-leveling technology, applied in the direction of lifting devices, etc., can solve the problems affecting the production efficiency of strands, the forklift support surface is not level, the spindle impact of the pay-off frame, etc., so as to avoid the impact damage of production equipment and update Low replacement cost, convenient and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

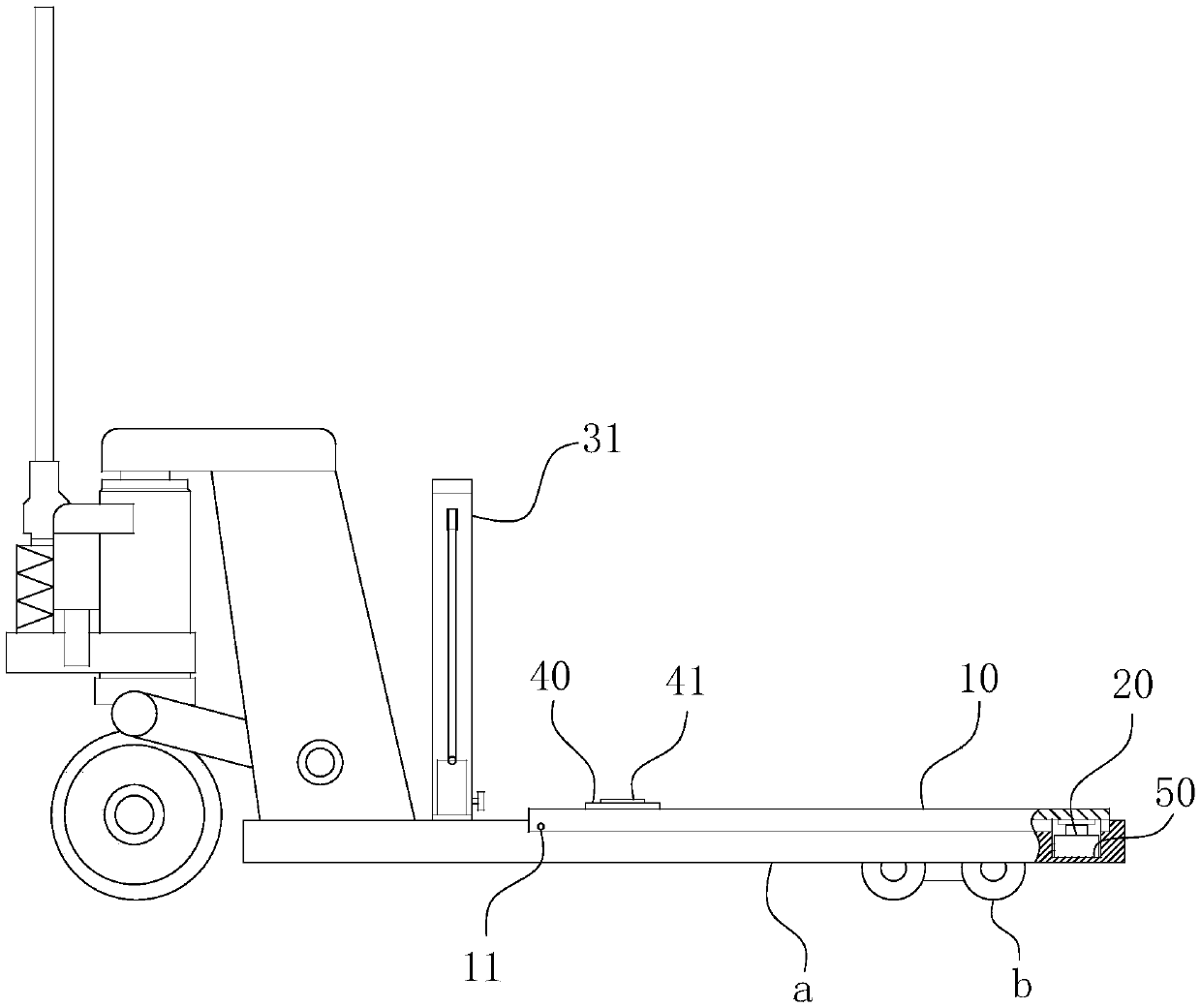

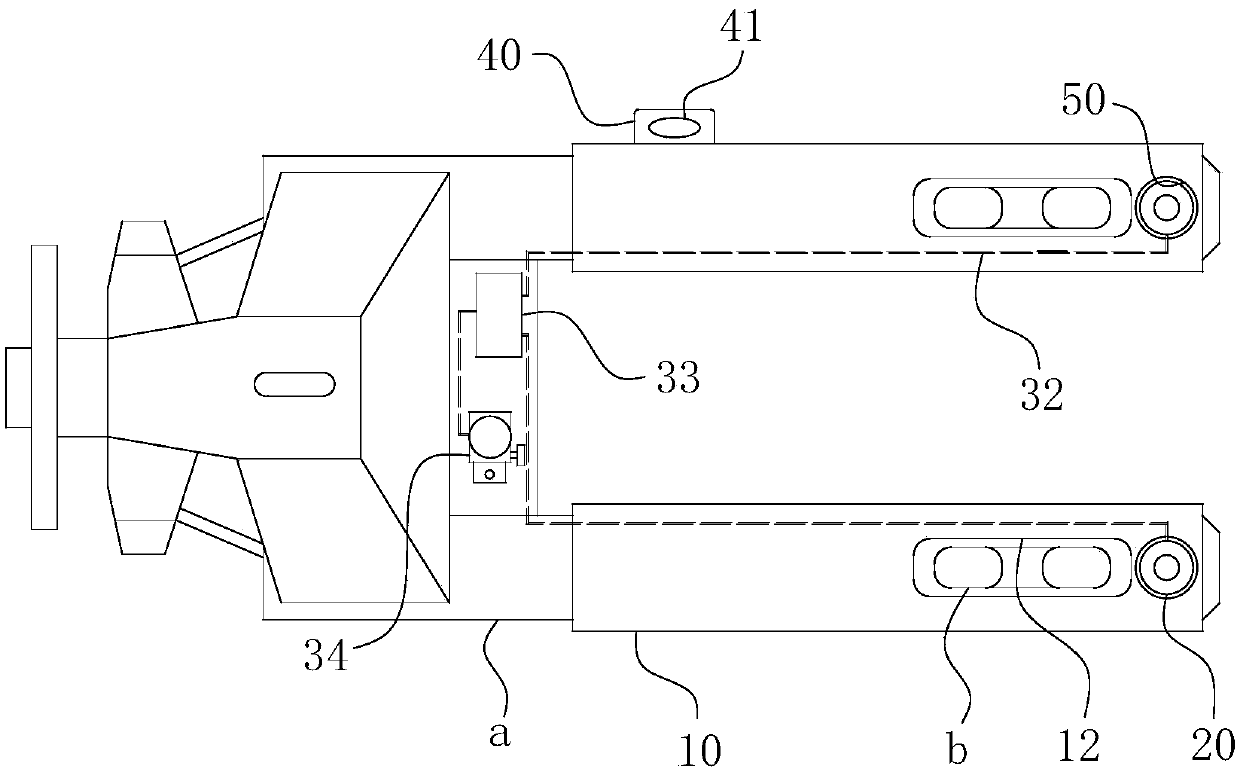

[0031] For ease of understanding, combined here Figure 1-3 , the concrete structure and working mode of the present invention are further described as follows:

[0032] The specific structure of the present invention is as Figure 1-3 As shown in the figure, its structure includes two sets of supporting claws a located in front of the vehicle body to carry the load. The two sets of supporting claws a are closed at the rear end and driven by the rollers at the rear end. Head end roller b.

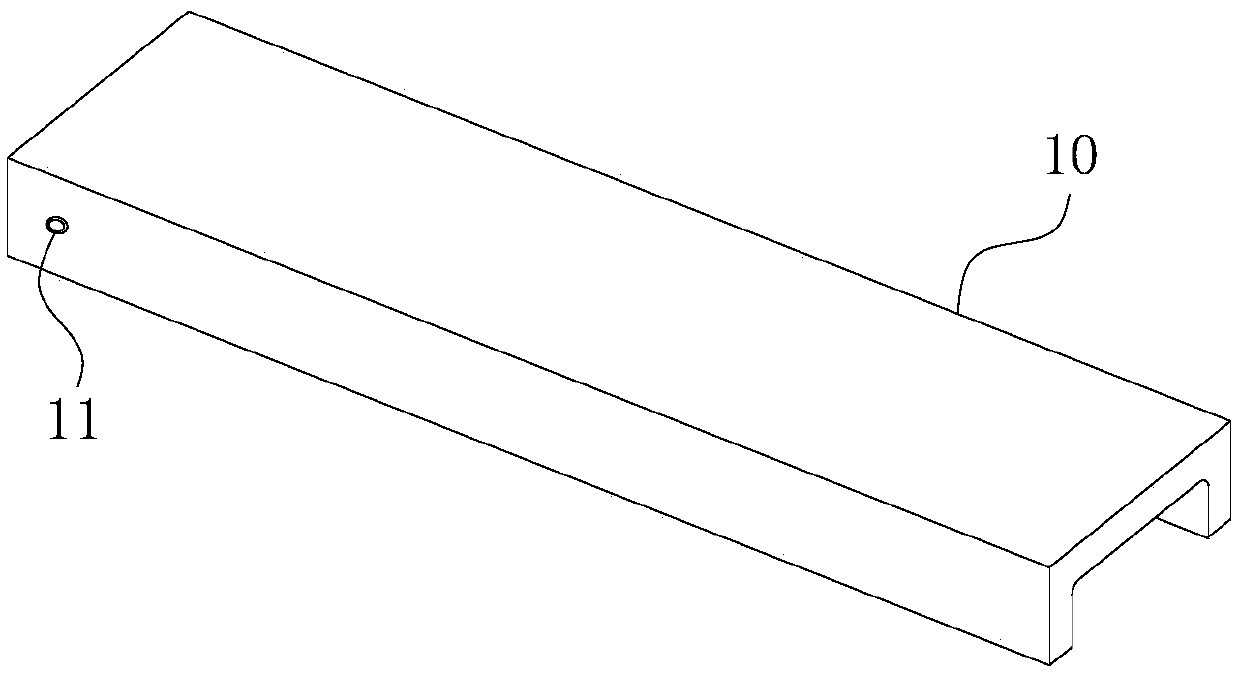

[0033] On the basis of the above structure, the present invention also includes a movable support plate 10 buckled on the upper surface of the two sets of support claws a. Refer to the shape of movable support plate 10 image 3 As shown, it is a right-angled groove with the opening facing downward, and the groove width of the movable support plate 10 must be greater than the width of the corresponding support claw a, so that the movable support plate 10 can be used as figure 1 The one s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com