Internet of things production monitoring management system for ring spinning frames

A technology of monitoring and management and spinning frame, which is applied in the direction of textiles and papermaking, can solve limitations and other problems, and achieve the effects of saving time, improving economic benefits, and efficiently monitoring and operating spinning production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

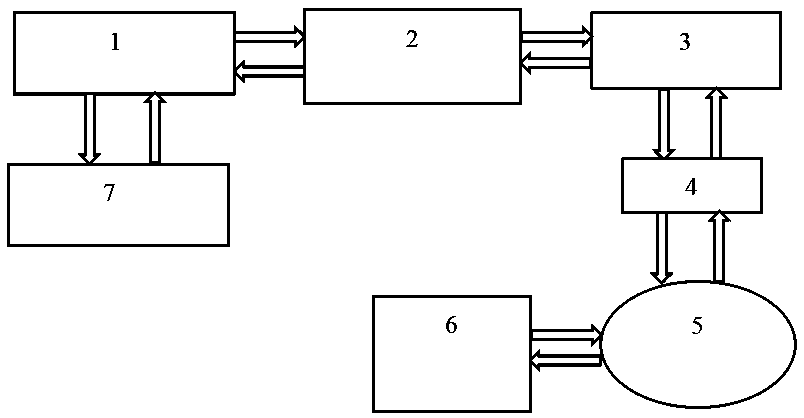

[0022] Such as figure 1 As shown, the present invention transmits the required production information in the ring spinning frame adopting electronic drafting to the gateway through the Zigbee wireless transmission device, and then transmits it to the local server by the gateway through the local area network. Monitoring and management software to realize the monitoring of the spinning production process and the setting and management of production parameters.

[0023] The present invention relates to a ring spinning machine Internet of Things production monitoring and management system, including the underlying data acquisition system, information transmission system, intelligent management and control platform system,

[0024] The underlying data acquisition system includes a ring spinning frame operation system, bobbin quality traceability syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com