Two-way composite slab bottom plate in dense seam splicing connection and construction method thereof

A construction method and technology of laminated slabs, which are applied in the directions of floor slabs, building components, building insulation materials, etc., to achieve the effects of improving construction quality, avoiding joint cracking, and reducing the amount of high-altitude construction work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

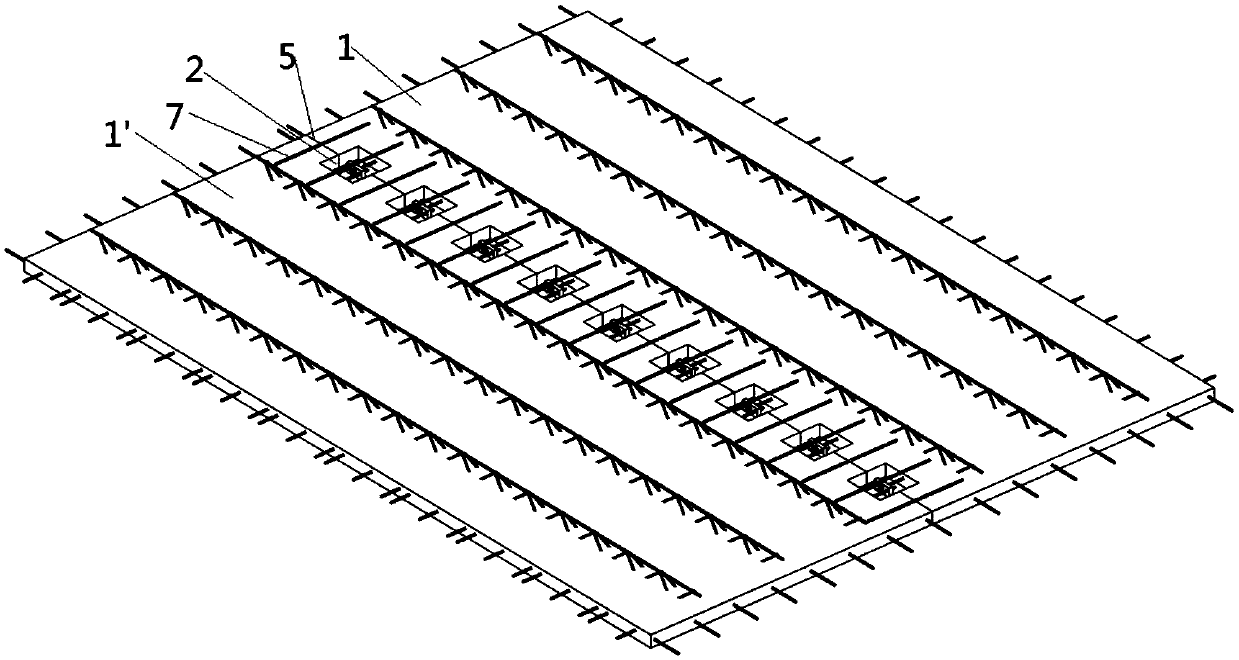

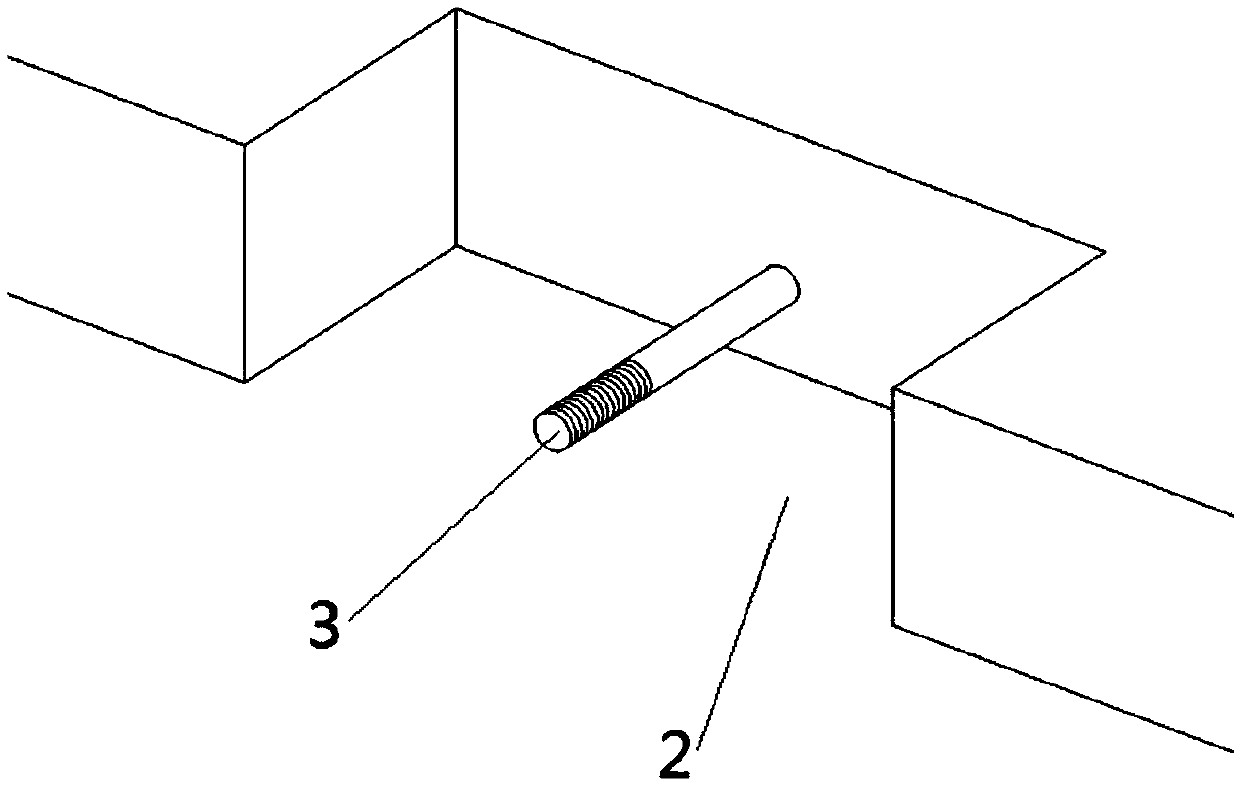

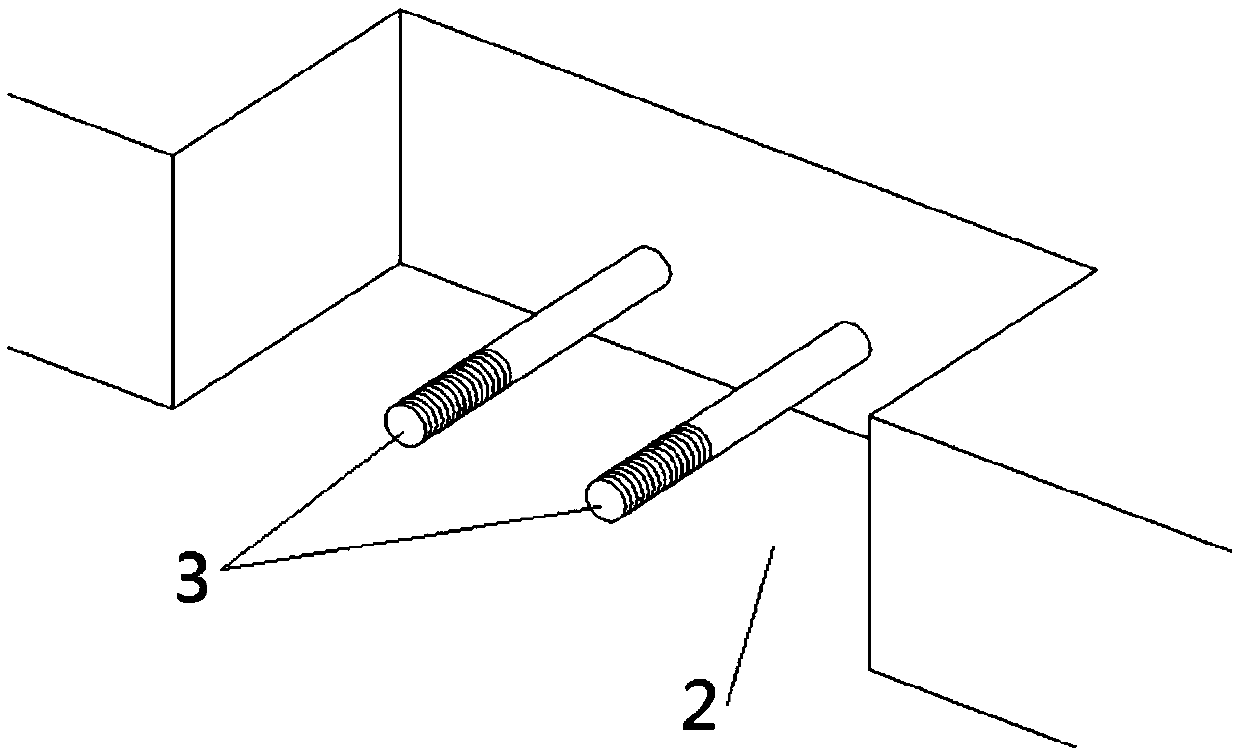

[0042] The scheme of the present invention will be further described below in conjunction with specific examples, as figure 1 As shown, the bottom plate of the two-way laminated board is formed by the close-fitting connection of the first veneer 1 and the second veneer 1'. There is a post-casting groove 2 at every interval between the joints 5 of the two veneers. In the pouring groove 2, the connecting steel bar 3 is pre-embedded. Among the two connected veneers, the connecting steel bar 3 in the post-casting groove 2 of one of them is one (such as figure 2 As shown, a connecting steel bar 3 is pre-embedded in the back groove of the first veneer 1, and there are two connecting steel bars 3 in the corresponding rear pouring groove 2 of the other piece (such as image 3As shown, two connecting steel bars 3) are pre-embedded in the rear groove of the second veneer 1'. All connecting bar ends shall be pre-threaded. The connecting steel bars are connected by steel bar connectors...

Embodiment 2

[0054] Such as Figure 7 As shown, the bottom plate of the two-way laminated board in this embodiment is formed by three single boards closely connected by seams, and the rest of the technical parameters are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com