Welding device for electric resistance welded pipe

A technology of electric resistance welded pipe and welding device, which is applied in the direction of high frequency current welding equipment, welding equipment, tubular articles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

[0114] Hereinafter, the resistance welded pipe welding device according to the second embodiment of the present invention will be described.

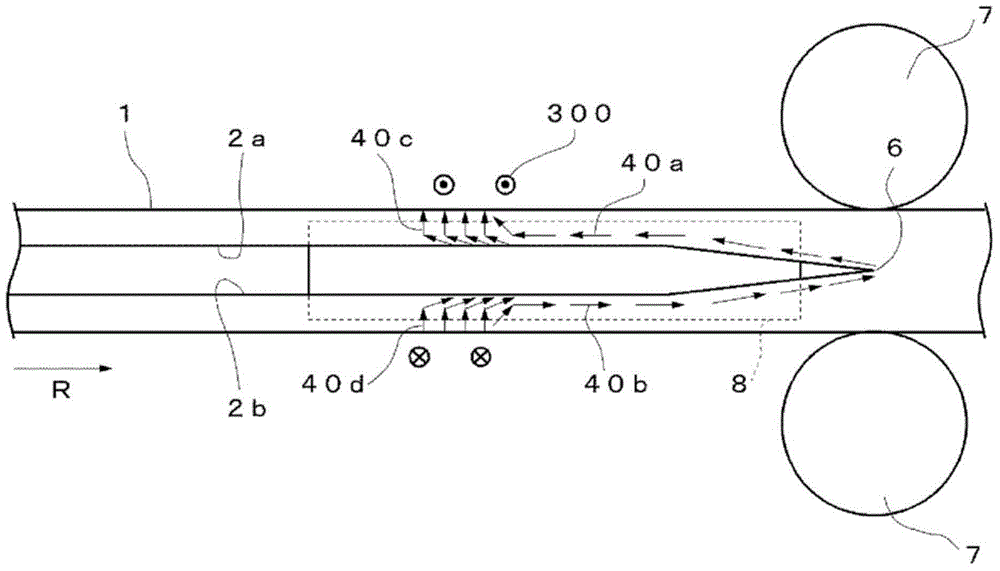

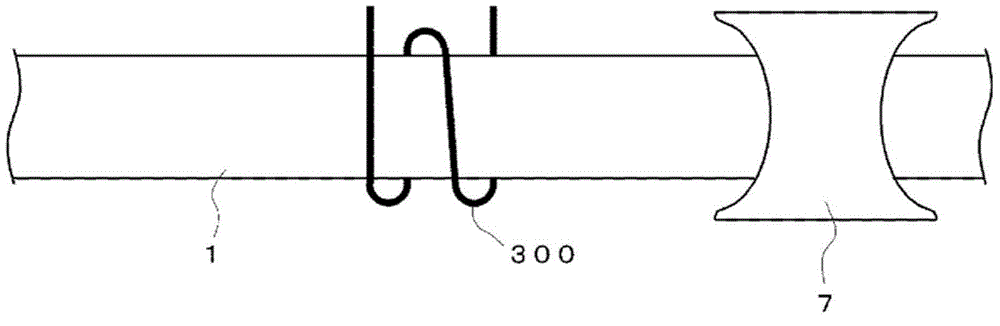

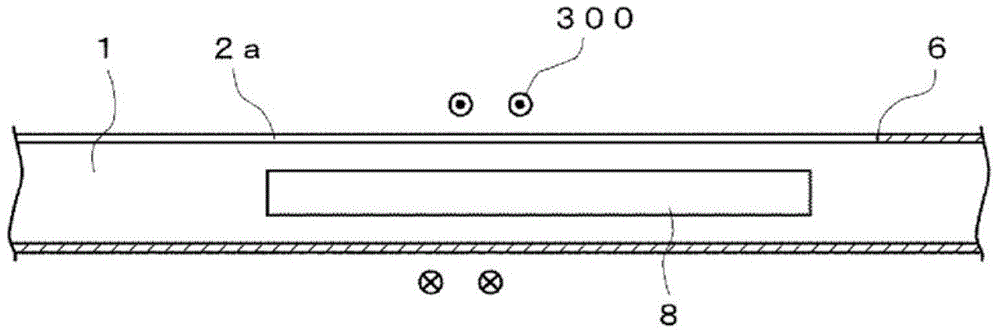

[0115] Figure 25 Is a schematic plan view showing the resistance welded pipe welding device 60 of the second embodiment of the present invention, Figure 26 Is a schematic representation in use Figure 25 The shown resistance welded pipe welding device 60 is a plan view of the distribution of the induced current generated during resistance welded pipe welding.

[0116] In the first embodiment described above, the case where the first ferromagnetic body 9 is arranged on the upstream side of the first induction coil 3 to suppress the induced current flowing to the upstream side of the first induction coil 3 has been described, but in this embodiment The structure adopted in the first induction coil 3 is provided on the upstream side of the first induction coil 3 to flow a primary current conductor, thereby similarly suppressing the upstream in...

no. 3 approach

[0132] Hereinafter, the resistance welded pipe welding device of the third embodiment of the present invention will be described.

[0133] Figure 34 Is a schematic plan view showing a resistance welded pipe welding device 70 according to the third embodiment of the present invention, Figure 35 Is to illustrate the use Figure 34 When the shown resistance welded pipe welding device 70 performs resistance welded pipe welding, the magnetic flux M generated by the first induction coil 3 passes through the ferromagnetic body (fifth ferromagnetic body) 12 in a schematic side view of the magnetic flux direction. Figure.

[0134] In this embodiment, in order to further improve the induction heating efficiency compared with the above-mentioned first and second embodiments, a configuration as exemplified below is adopted. In this embodiment, the same reference numerals are assigned to the same configurations in the first and second embodiments, and detailed descriptions thereof are omitted...

Embodiment 1

[0152] "The heated material"

[0153] In this embodiment, as the heated material, the following materials are used: the upper part of carbon steel pipe (SGP pipe) for piping with outer diameter: 318.5mm, wall thickness: 6.9mm, and length: 1m, such as Figure 44 As shown, a material that simulates the shape of the opening is processed by laser (hereinafter referred to as an open tube). The laser processing at this time is from Figure 44 The left end in the middle is opened according to the interval of the parallel opening: 50mm, length: 200mm, and then the angle between the vertex and both ends of the joint is 5.7 degrees, and the length is 500mm (total openings Is 700mm). In addition, the vertex is 0.5R.

[0154] "Electric resistance welded pipe welding device"

[0155] In the resistance welded pipe welding device used in this embodiment, as the induction coil, the following coil is used: The water-cooled copper pipe is 200mm in the upstream and downstream direction and 200mm in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com