A high-rise aluminum formwork composite structure

A combined structure and aluminum formwork technology, which is applied in building structure, formwork/formwork components, buildings, etc., can solve the problems of increasing the gap of aluminum formwork, affecting the smoothness of the wall surface, and increasing the labor intensity of staff, etc., to achieve Improves strength, reduces the risk of cracks, and prolongs the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

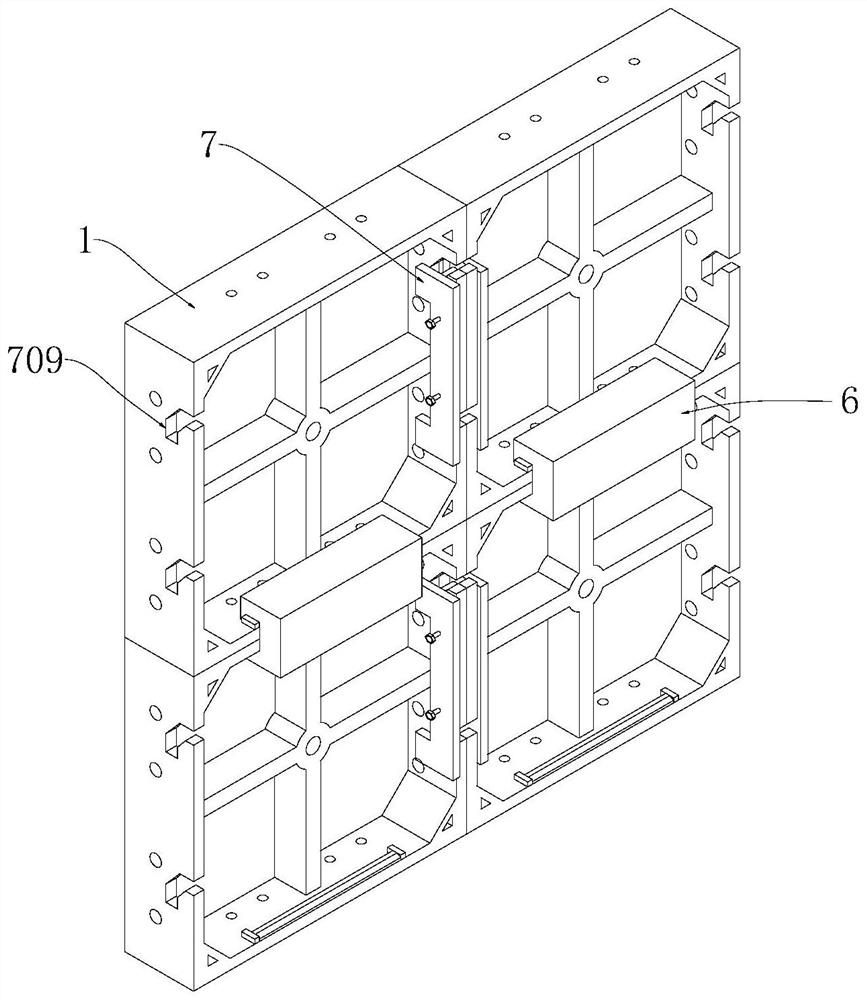

[0039] Such as figure 1 , figure 2 , Figure 9 , Figure 10, Figure 12 and Figure 14 As shown, a composite structure of high-rise aluminum formwork of the present invention includes a formwork body 1 and a reinforcement plate 2 arranged on the formwork body 1, a connecting column 3 is provided in the middle of the reinforcement plate 2, and a plurality of Reinforcing ribs 4, the four sides of the formwork body 1 are provided with a plurality of bolt holes 5, the strength of the formwork body 1 can be improved through the reinforcement plate 2, the strength of the reinforcement plate 2 can be improved through the connecting column 3, and the length of the reinforcement plate 2 can be extended. For the service life, the strength at the corner of the formwork body 1 can be improved through the ribs 4, thereby reducing the risk of damage to the formwork body 1, which also includes:

[0040] The first connecting mechanism 6 or the third connecting mechanism 8 arranged on a ...

Embodiment 2

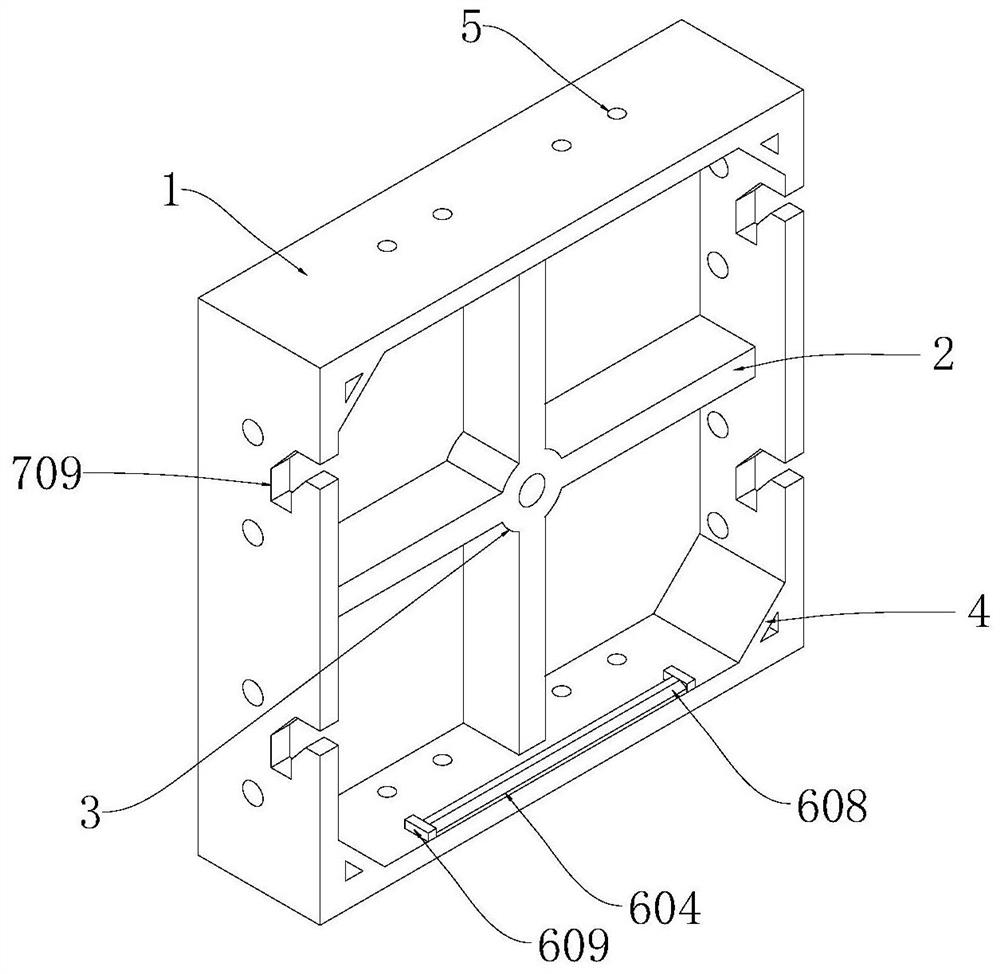

[0046] Such as Figure 5 , Figure 6 , Figure 11 , Figure 12 and Figure 14 As shown, a composite structure of high-rise aluminum formwork of the present invention includes a formwork body 1 and a reinforcement plate 2 arranged on the formwork body 1, a connecting column 3 is provided in the middle of the reinforcement plate 2, and a plurality of Reinforcing ribs 4, the four sides of the formwork body 1 are provided with a plurality of bolt holes 5, the strength of the formwork body 1 can be improved through the reinforcement plate 2, the strength of the reinforcement plate 2 can be improved through the connecting column 3, and the length of the reinforcement plate 2 can be extended. For the service life, the strength at the corner of the formwork body 1 can be improved through the ribs 4, thereby reducing the risk of damage to the formwork body 1, which also includes:

[0047] The first connection mechanism 6 or the third connection mechanism 8 arranged on both sides of...

Embodiment 3

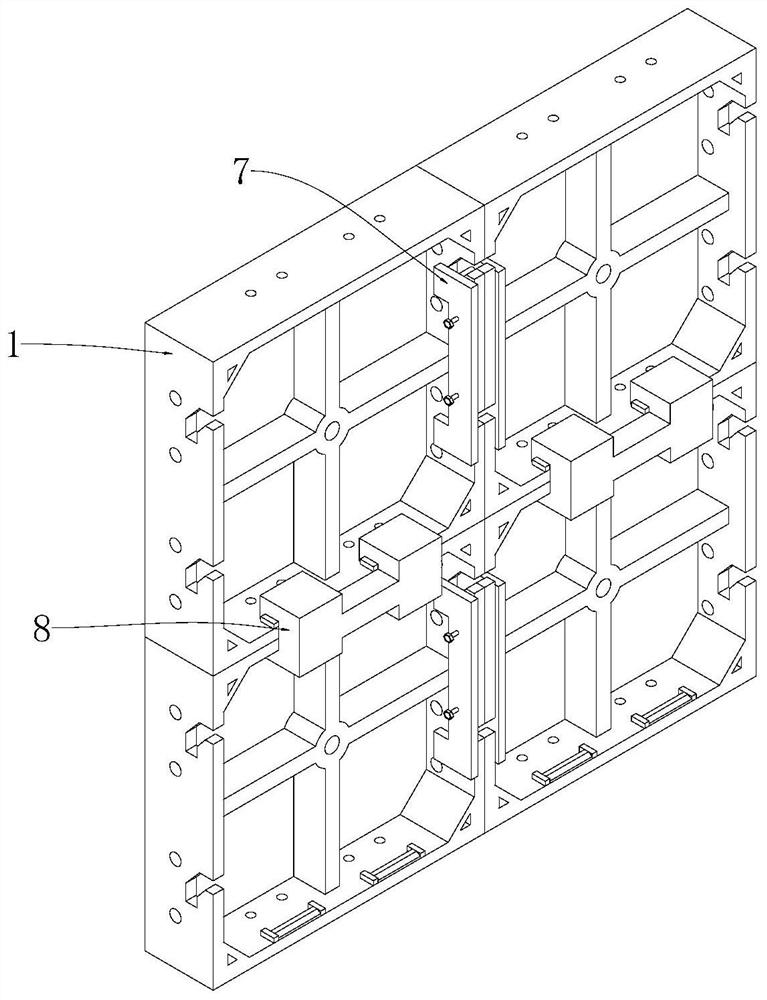

[0054] Such as image 3 , Figure 4 , Figure 9 , Figure 10 and Figure 13As shown, a composite structure of high-rise aluminum formwork of the present invention includes a formwork body 1 and a reinforcement plate 2 arranged on the formwork body 1, a connecting column 3 is provided in the middle of the reinforcement plate 2, and a plurality of Reinforcing ribs 4, the four sides of the formwork body 1 are provided with a plurality of bolt holes 5, the strength of the formwork body 1 can be improved through the reinforcement plate 2, the strength of the reinforcement plate 2 can be improved through the connecting column 3, and the length of the reinforcement plate 2 can be extended. For the service life, the strength at the corner of the formwork body 1 can be improved through the ribs 4, thereby reducing the risk of damage to the formwork body 1, which also includes:

[0055] The first connection mechanism 6 or the third connection mechanism 8 arranged on both sides of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap