Aluminum alloy rapid template system and construction method thereof

An aluminum alloy and formwork technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of heavy steel formwork, time-consuming, inconvenient installation, etc., and achieve large concrete area , reduced man-hours, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

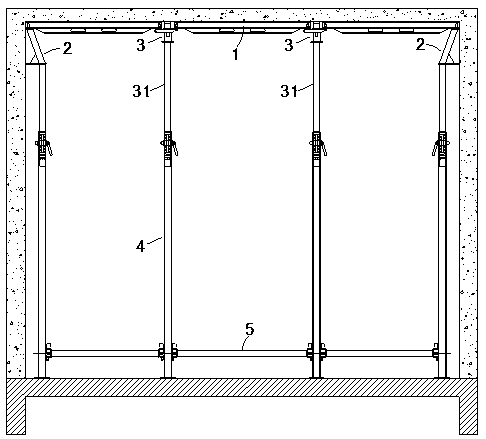

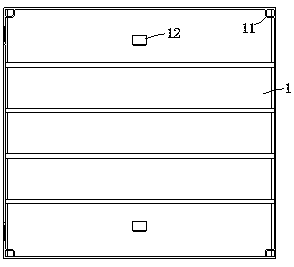

[0052] Such as Figure 1 to Figure 15 As shown, an aluminum alloy quick formwork system includes a formwork system, a support system and a connection system. The formwork system includes a plurality of quick-release formworks 1 spliced with each other. Corner bars 11 are provided at the four corners of the quick-release formwork 1. The support system includes a support assembly 2 arranged at the four corners of the quick-release template 1 and connected to the corner ribs 11, and the early-release head 3 connecting two adjacent quick-release templates 1;

[0053] Early detachment head 3 comprises support inner tube 31, and the top of support inner tube 31 is connected with support bottom bracket 32, and the top of support bottom bracket 32 is connected with support jack 33 by limit support mechanism, and described limit support mechanism comprises support bracket 34 And the limiting plate 35 installed on the outside of the supporting bracket 34, the supporting bracket 34 i...

Embodiment 2

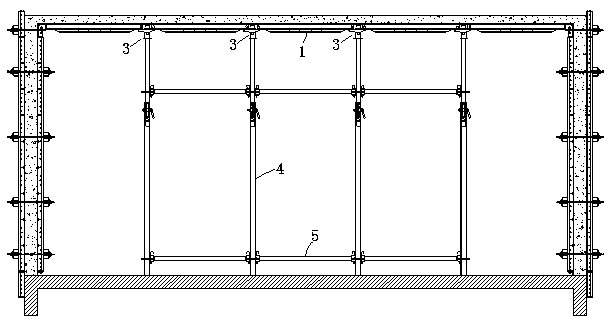

[0082] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the method of combining with the common formwork is adopted, and the side support of the wall is cancelled. This example is applicable to the case of one-time pouring of wall panels and roof panels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com