Medium and low pressure gas-liquid separation device and method suitable for multiple working conditions

A technology of low-pressure gas-liquid separation and gas-liquid separator, which is applied in gas/liquid distribution and storage, earthwork drilling, mining fluid, etc. It can solve the problems that cannot meet the requirements of the production period, and achieve the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

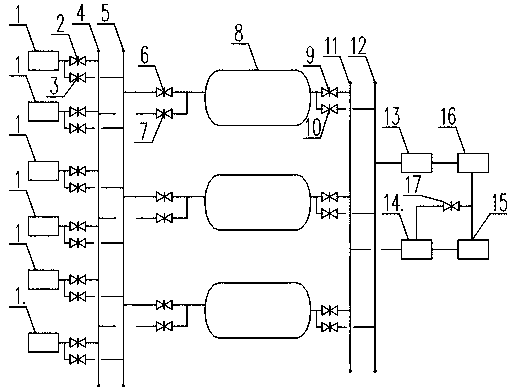

[0025] Due to the different requirements for gas-liquid separation in different development periods, conventionally designed gas-liquid separation devices cannot meet the requirements of the production period and the needs of downstream users. The present invention provides such figure 1 The shown is a medium-low pressure gas-liquid separation device and method suitable for multiple working conditions, which can meet the gas-liquid separation requirements of gas-gathering stations in different operation periods, and at the same time can realize low-pressure natural gas pressurized and exported to meet the needs of downstream users to improve the gas field. recovery rate.

[0026] A medium-low pressure gas-liquid separation device suitable for multiple working conditions, including a plurality of gas well inlet pipelines 1, a first low-pressure header 4 and a first medium-pressure header 5, a second low-pressure header 11, a second medium-pressure Manifold 12, compressor 15, ex...

Embodiment 2

[0032] Based on Embodiment 1, a third process switching valve 7 is provided between the first low-pressure manifold 4 and each gas-liquid separator 8 in this embodiment.

[0033] A fourth process switching valve 6 is arranged between the first medium pressure manifold 5 and each gas-liquid separator 8 .

[0034] A low-pressure flow meter 14 is provided between the second low-pressure manifold 11 and the compressor 15 .

[0035] A valve 17 is provided between the low-pressure flow meter 14 and the compressor 15 .

[0036] The valve 17 is a bypass valve.

[0037] A medium-pressure flowmeter 13 is arranged between the second medium-pressure manifold 12 and the outgoing pipeline 16 .

[0038] A fifth process switching valve 9 is provided between the second low-pressure manifold 11 and each gas-liquid separator 8 .

[0039] A sixth process switching valve 10 is provided between the second medium pressure manifold 12 and each gas-liquid separator 8 .

[0040] The gas well inlet ...

Embodiment 3

[0043] Based on the basis of Examples 1 and 2, a medium-low pressure gas-liquid separation method suitable for multiple working conditions is provided in this example, and the specific steps are:

[0044]Step 1. The gas well inlet pipeline 1 is switched to the header through the first process switching valve 2 and the second process switching valve 3 according to whether the inlet pressure is greater than the downstream external pressure. If it is greater than the downstream external pressure, the first process is closed. Switch valve 2, open the second process switching valve 3 to enter the first medium pressure manifold 5, otherwise close the second process switching valve 3, open the first process switching valve 2 to enter the first low pressure manifold 4;

[0045] Step 2. According to the total amount of low-pressure and medium-pressure gas entering the gas gathering station, the gas-liquid separator 8 is used as a medium-pressure separator or a low-pressure separator. As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com