Three-guiding-rod synchronous variable pitch device and assembling method thereof

A technology of guide rods and synchronous discs, which is applied in the assembly of wind turbines, wind power generation, sustainable manufacturing/processing, etc., can solve problems such as unexpected changes in blade angles, jamming, and high manufacturing requirements, and achieve manufacturing requirements and costs. The effect of reducing the size of the hub and improving the mounting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

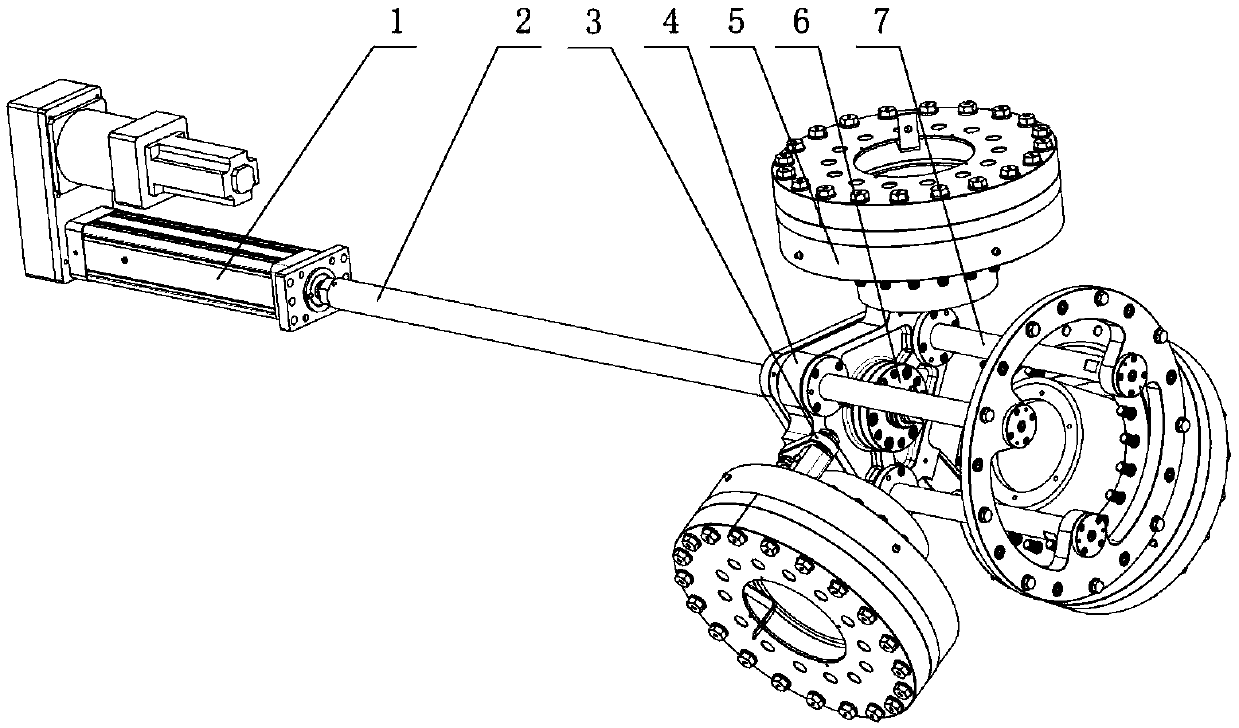

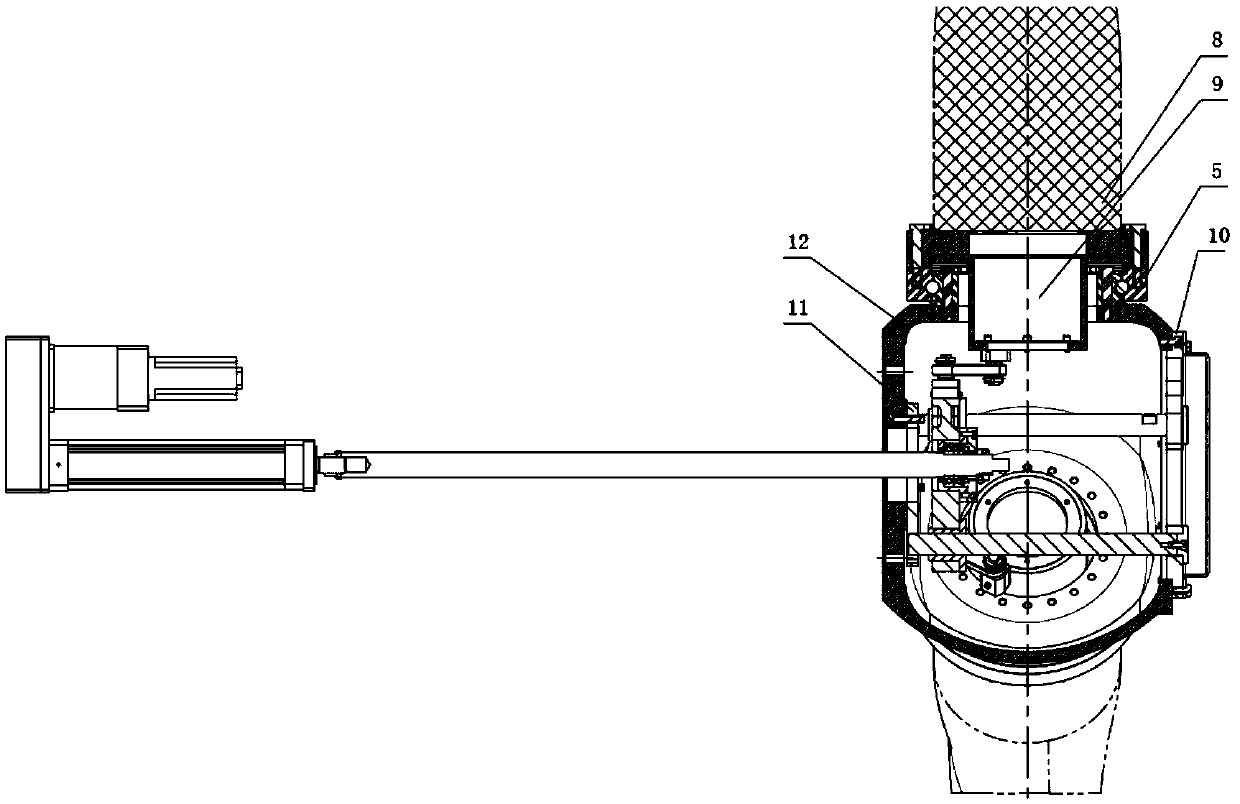

[0021] like figure 2 As shown, the three-guide rod synchronous pitch device of the present invention includes a blade slewing bearing 5, the outer ring of the blade slewing bearing 5 is connected to the blade 8, the inner ring is connected to the hub 12, and the outer ring of the blade slewing bearing 5 passes through The connecting rod 3 is connected to the synchronous disk 4, and the synchronous disk 4 is provided with three guide sleeves, and three guide rods 7 arranged in parallel are respectively arranged in the three guide sleeves, and the synchronous disk 4 can move forward and backward along the guide rods 7. The synchronous disc 4 is arranged in the hub, and the forward and backward movement of the synchronous disc 4 can drive the outer ring of the blade slewing bearing 5 to rotate, thereby realizing synchronous pitch change. Both ends of the guide rod 7 are respectively connected to the front mounting base 10 and the rear mounting base 11 , and the front mounting ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com