Range hood

A technology for range hoods and fume collection hoods, which is applied in the field of range hoods and can solve problems such as bumping and difficult cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

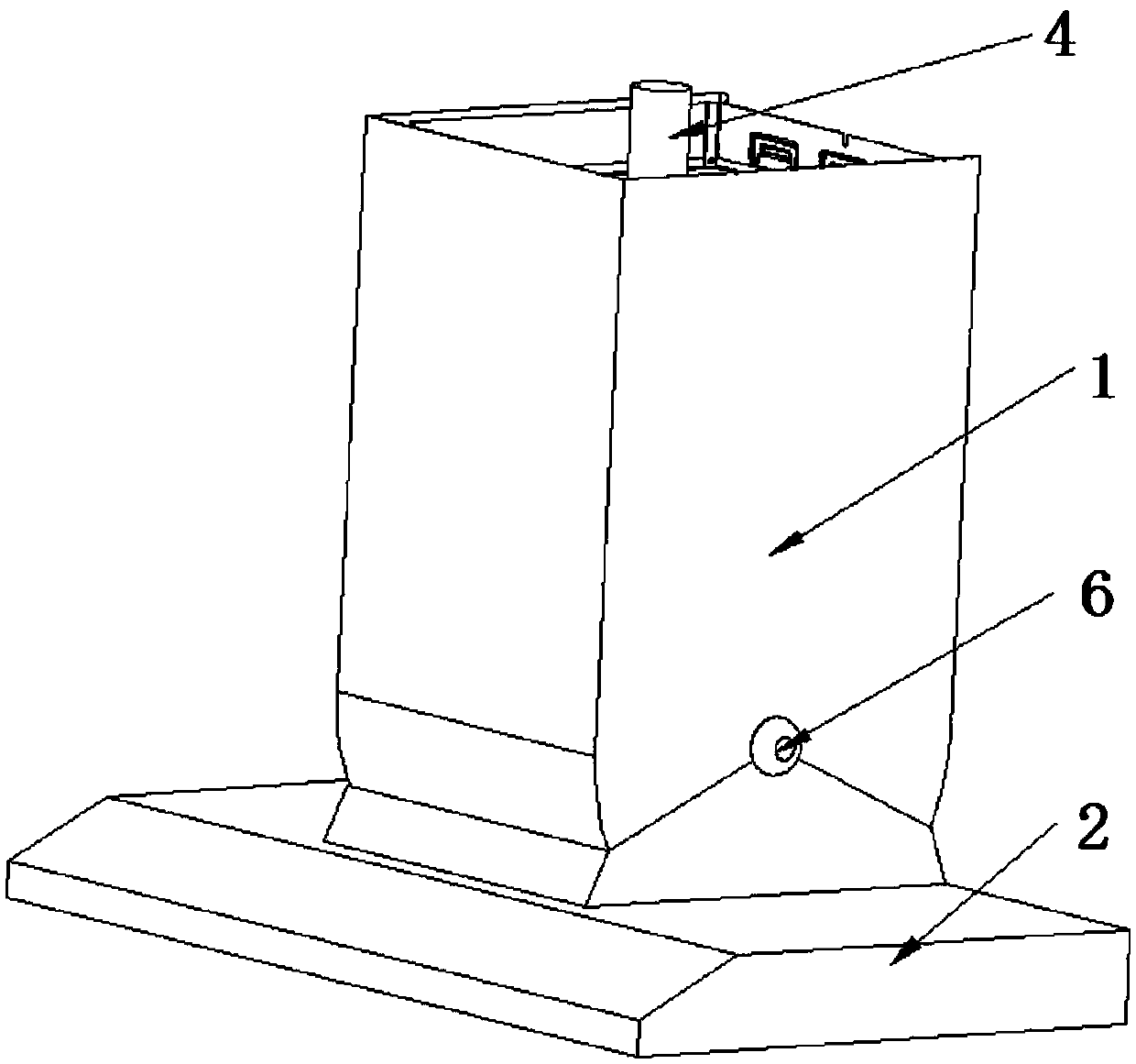

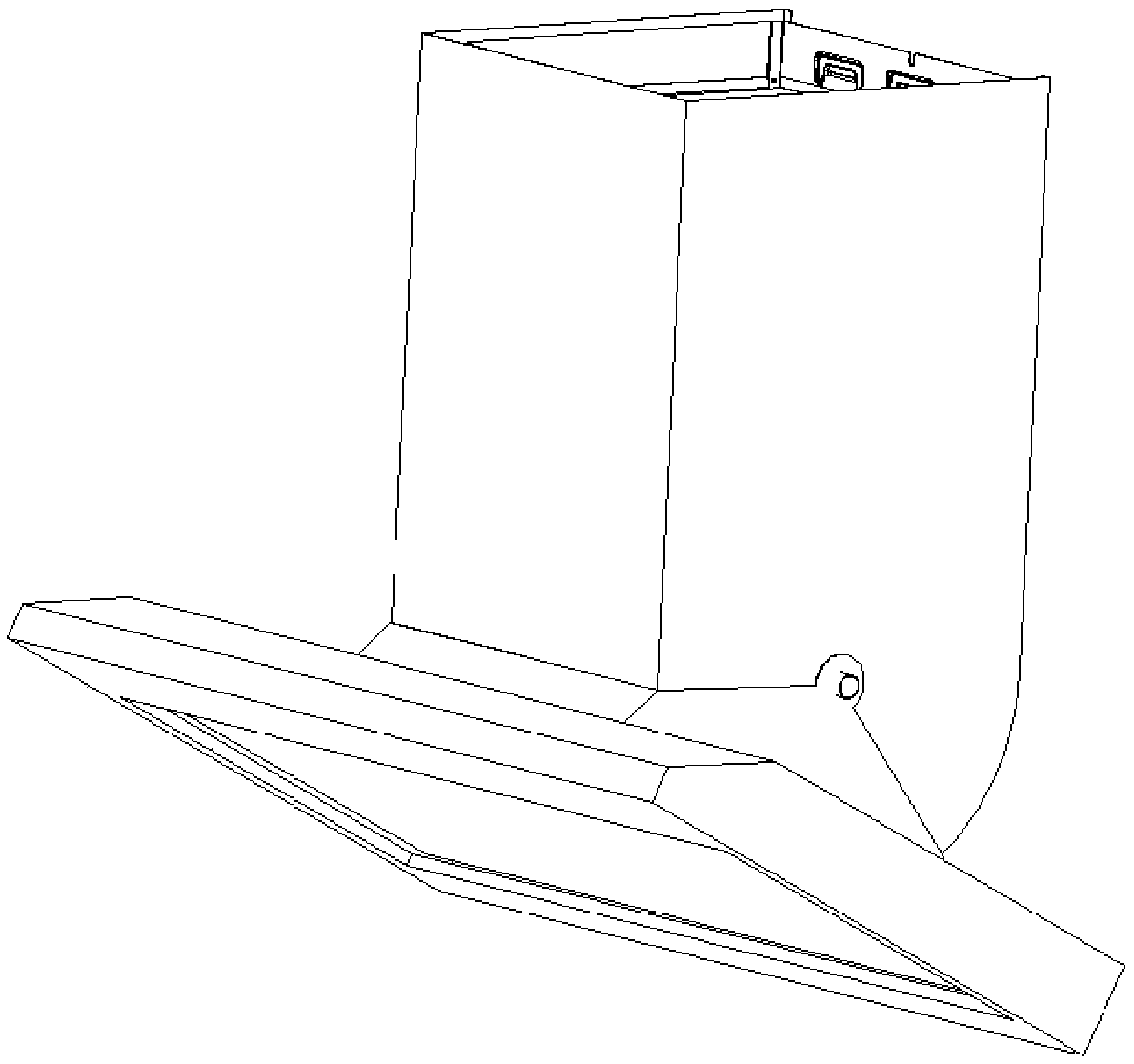

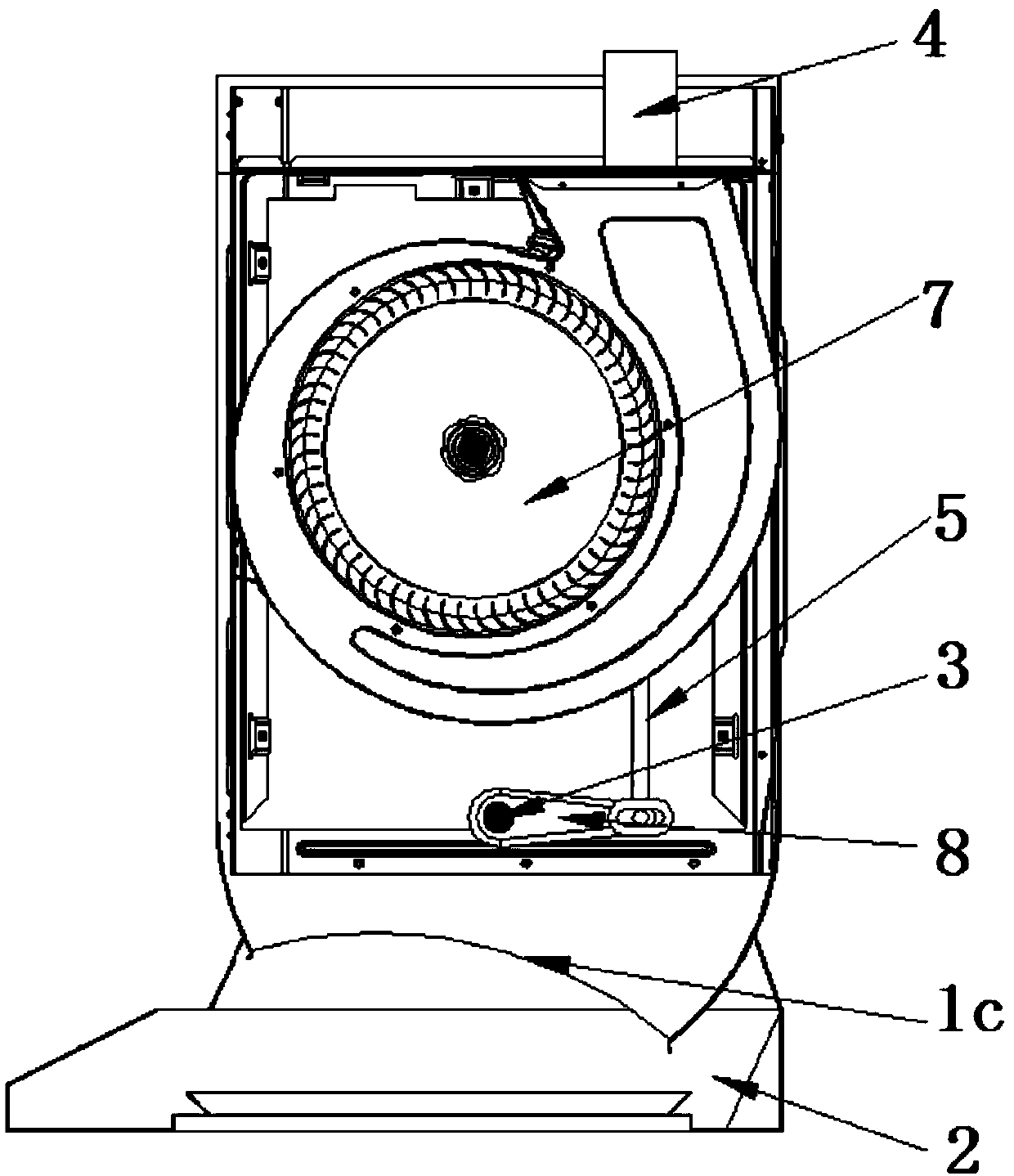

[0040] This embodiment provides a range hood, such as Figure 1-Figure 5 shown, including: Figure 8 The housing 1 shown has a fan system 7 inside; the smoke collecting hood 2 is rotatably connected to the housing 1, and the smoke enters the inside of the housing 1 through the fume collecting hood 2; the power device is arranged in the housing 1 Inside the casing 1, the fume collecting hood 2 has a top suction state perpendicular to the longitudinal axis of the casing 1, and a side suction state with a rotation angle α relative to the casing 1 driven by the power device.

[0041]In this embodiment, the fume collecting hood 2 itself is rotatably connected to the casing 1. In general, the longitudinal axes of the fume collecting hood 2 and the casing 1 are perpendicular to each other. At this time, the range hood is a top-suction type range hood; When it is necessary to change the range hood into a side-suction range hood, the power unit is activated to rotate the fume collecti...

Embodiment 2

[0054] This embodiment is made on the basis of Embodiment 1. In this embodiment, in order to realize the rotation of the rotating shaft 3, the combination of the motor 4 and the transmission pair is not used, but the output end of the motor 4 is directly connected to the on reel 3.

[0055] Specifically, the motor 4 can be arranged at the end of the rotating shaft 3 , and the motor 4 will be located outside the housing 1 at this time. The motor 4 acts synchronously with the rotating shaft 3 and the fume collecting hood 2, thereby completing the transition between the two states.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com