Drying device for tea processing

A drying device and tea technology, which is applied in the direction of tea drying, drying, drying machine, etc., can solve the problems of reducing tea drying efficiency, alternate air drying, poor drying effect, etc., and achieve good drying effect, improve the flow range, improve the effect of drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

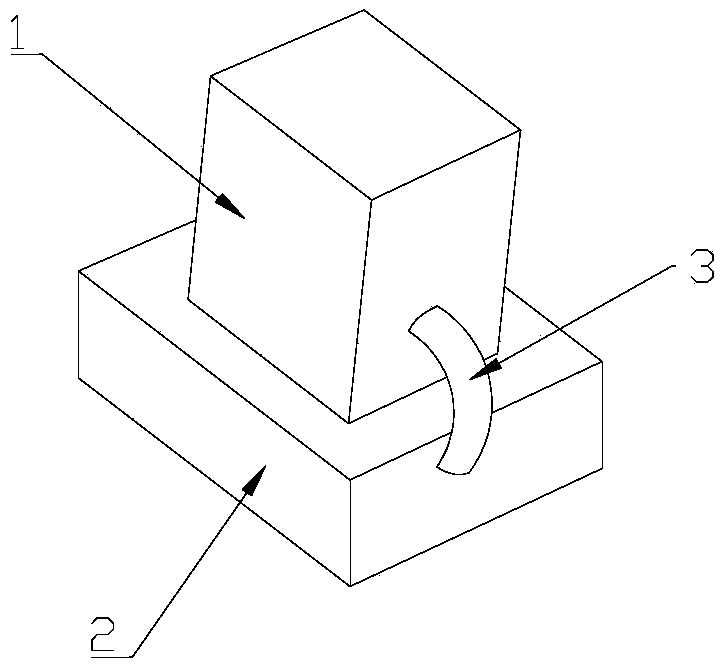

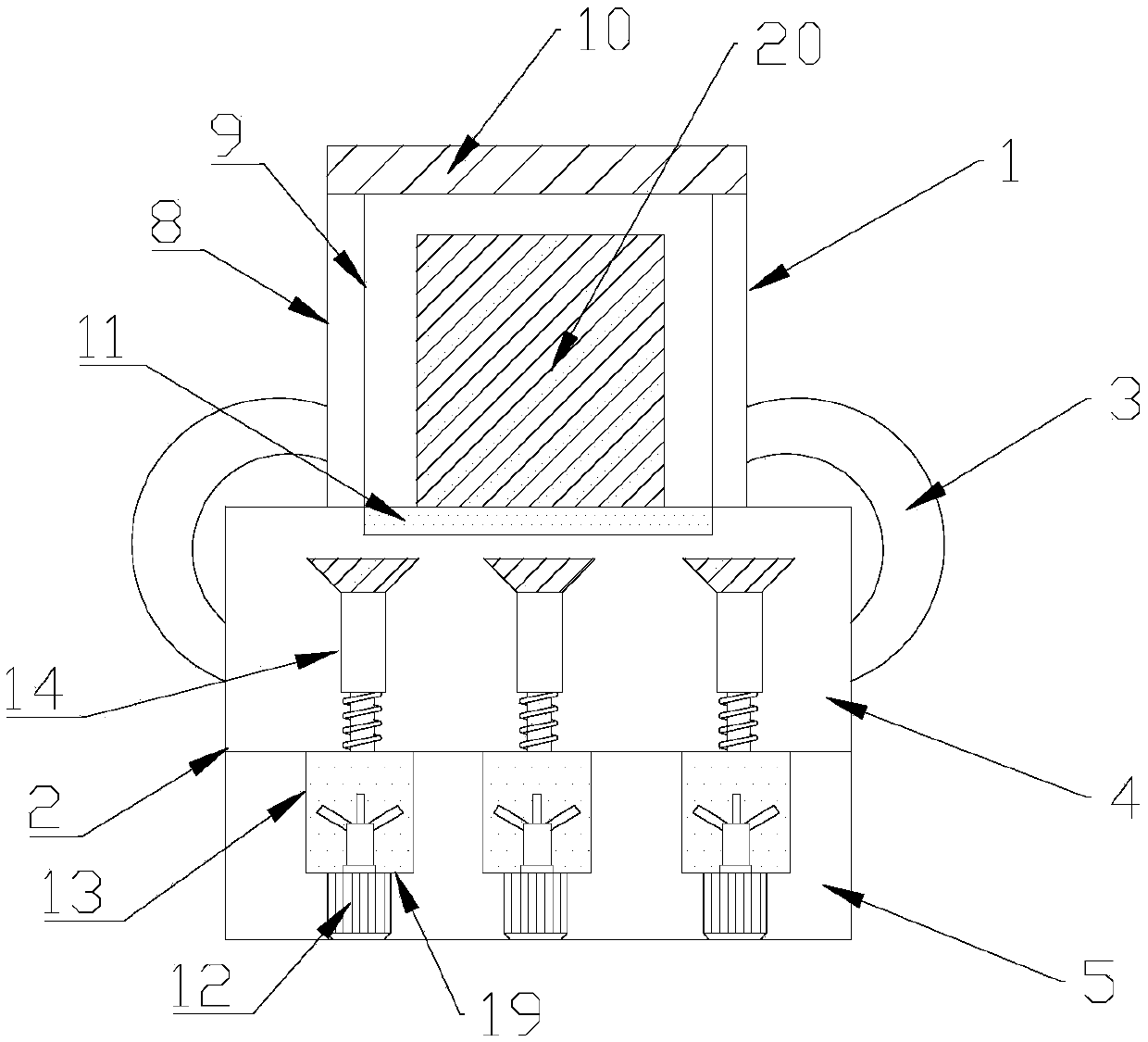

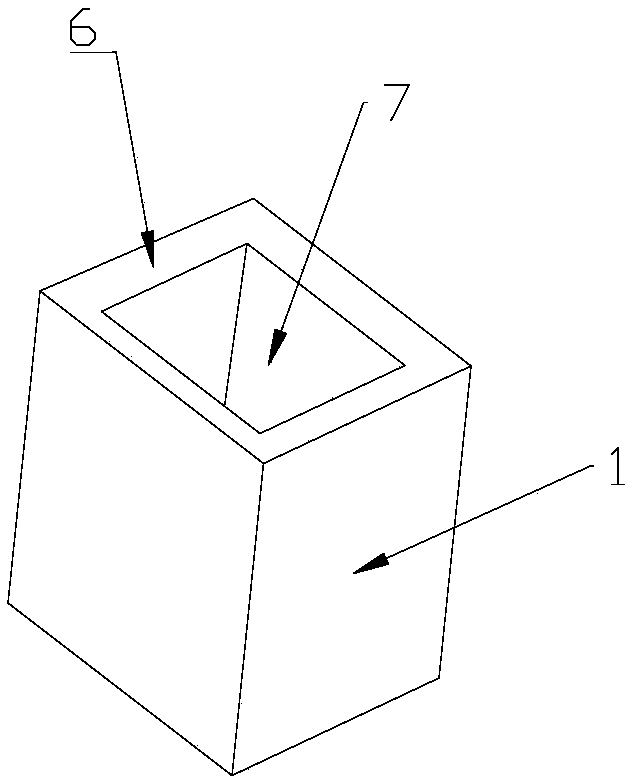

[0026] see Figure 1-5 , in an embodiment of the present invention, a drying device for tea processing, including a box 1 for placing tea leaves for drying, a drying system 2 for drying the tea leaves at the bottom, and a drying system for connecting the box 1 with the drying system. The circulation pipe 3 of the system 2, in order to improve the drying effect, there are two circulation pipes 3, which are symmetrically arranged on both sides of the box body 1, the circulation pipe 3 is spiral, and by setting the circulation pipe 3 to be spiral, Effectively extend the path of gas circulation, which is conducive to improving the drying effect;

[0027] In order to solve the problem of poor gas fluidity and poor drying effect due to the inability of the existing tea drying device to carry out alternate blowing and drying of far and near, the drying system 2 includes a ventilation box 4 and a delivery system connected to the lower end of the ventilation box 4. The bellows 5, the ...

Embodiment 2

[0033] see Figure 1-5 , in an embodiment of the present invention, a drying device for tea processing, including a box body 1, a drying system 2 and a circulation pipe 3, the drying system 2 is used to dry the tea leaves at the bottom, and the box body 1 For placing tea leaves, the circulation pipe 3 is used to communicate with the box body 1 and the drying system 2. There are two circulation pipes 3, which are arranged symmetrically on both sides of the box body 1. The circulation pipe 3 is spiral, By setting the circulation pipe 3 in a spiral shape, the path of gas circulation is effectively extended, which is beneficial to improve the drying effect;

[0034] In order to solve the problem of poor gas fluidity and poor drying effect due to the inability of the existing tea drying device to carry out alternate blowing and drying of far and near, the drying system 2 includes a ventilation box 4 and a delivery system connected to the lower end of the ventilation box 4. The bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com