Flying stopper for carbon dioxide fracturing device and fracturing device

A technology of carbon dioxide and cracker, which is applied in the direction of weapon accessories, blasting barrels, blasting, etc., can solve the problems of complex structure, inconvenient use, and low anti-flying effect of the anti-flying device, so as to avoid the phenomenon of unsuccessful anti-flying and facilitate maintenance , The effect of improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

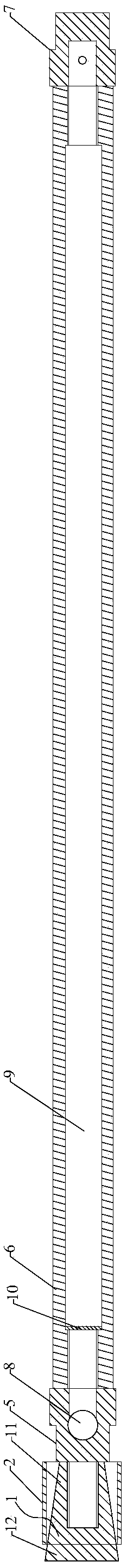

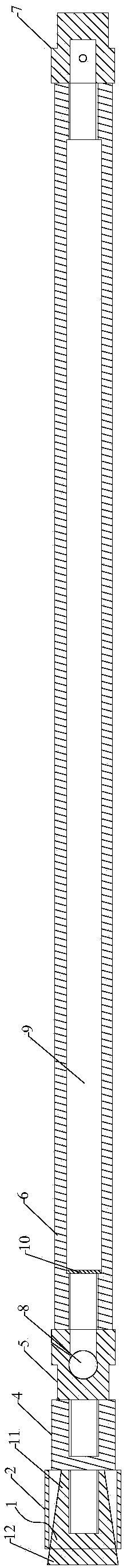

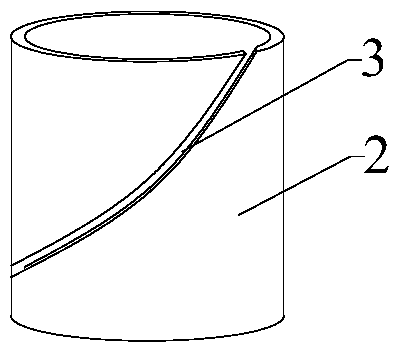

[0041] like figure 1 , image 3 As shown, a flight arrester for a carbon dioxide cracker includes a limit reel 2, and the limit reel 2 is sleeved on the flight stop seat 1 for connecting with the cracker and preventing the cracker from flying out. The seat 1 includes a small end 11 arranged in the limit reel 2 and a large end 12 extending out of the limit reel 2 and connected to the small end 11, the small end 11 is connected with the cracker, and the limit roll The tube 2 is cylindrical and is provided with a gap 3 spirally arranged along its surface. The limit reel 2 is parallelogram after unfolding along the gap 3, and the small end 11 and the large end 12 form a circular truncated shape.

[0042] In this embodiment, the flystop includes a limit drum 2, which is cylindrical and is provided with a gap 3 that is spirally arranged along the surface of the limit drum 2, and the limit drum 2 and the small end There is an annular space between the parts 11, which is convenient ...

Embodiment 2

[0046] like figure 1 , image 3 , Figure 7 As shown, a flight arrester for a carbon dioxide cracker includes a limit reel 2, and the limit reel 2 is sleeved on the flight stop seat 1 for connecting with the cracker and preventing the cracker from flying out. The seat 1 includes a small end 11 arranged in the limiting reel 2 and a large end 12 protruding from the limiting reel 2, the small end 11 is connected with the cracker, the limiting reel 2 is cylindrical and It is provided with a slit 3 spirally arranged along the surface of the limit reel 2, and the limit reel 2 is parallelogram after being unfolded along the slit 3, the small end 11 and the large end 12 are cylinders, and the small end 11 The outer diameter is smaller than the outer diameter of the large end portion 12 .

[0047] In this embodiment, both the small end portion 11 and the large end portion 12 are cylinders. When the limiting reel 2 is expanded under pressure, the large end portion 12 is directly rest...

Embodiment 3

[0049] like figure 1 , image 3 , Figure 8 As shown, a flight arrester for a carbon dioxide cracker includes all the structures of Embodiment 2, and also includes: a connecting portion 13 is provided between the small end portion 11 and the large end portion 12, the connecting portion 13 is in the shape of a circular truncated cone, and the connecting portion The outer diameter of the end connected to the small end 11 is the same as that of the small end 11 , and the outer diameter of the end connected to the large end 12 of the connecting portion 13 is the same as that of the large end 12 .

[0050] In this embodiment, when the limiting reel 2 is expanded under pressure, the connecting part 13 and the large end 12 are restricted by the limiting reel 2 and are stuck outside the limiting reel 2 and cannot continue to move upwards. The setting of the part 13 plays a buffering role, thereby effectively preventing the cracker from flying out towards the blasting hole, avoiding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com