Pluggable modular box with expansibility

A scalable, box-like technology, applied in the field of urban public equipment, can solve problems such as the inability to realize plug-and-play functional modules, no corresponding disclosure, modular box volume water, etc., to achieve convenient power supply, communication, and design Ingenious, easy to integrate and install the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Please refer to figure 1 , figure 1 It is a structural schematic diagram of an expandable pluggable modular box invented by the invention. A pluggable modular box with expandability, the modular box includes a module box body 1 and an interface module 2.

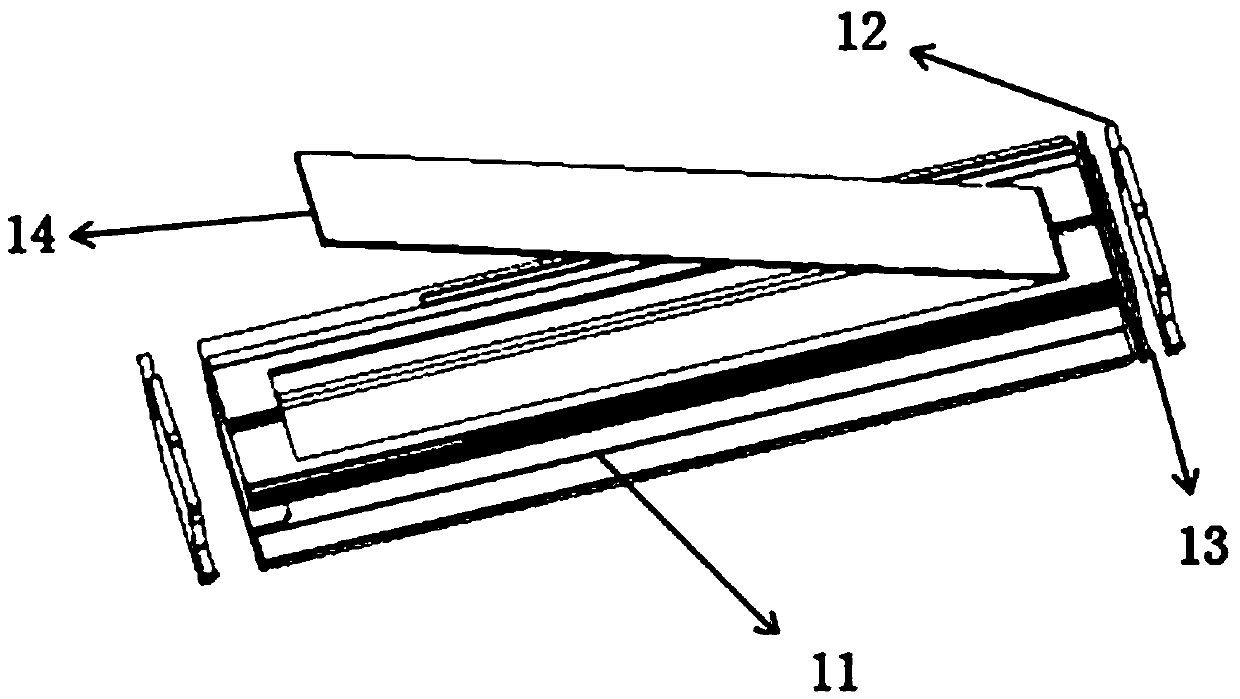

[0066] Please refer to figure 2 , figure 2 It is a schematic diagram of the structure of the modular box. Described module case body 1 comprises box body main body 11; Box body main body 11 both sides are equipped with sealing plate 12 by bolt, and the outer side of described sealing plate 12 is equipped with waterproof gasket 13; Plate 14 forms an electrical cavity 15 inside, and the flap 14 is hinged with the box body 11; the flap 14 is integrally formed with the box body 11 and then cut; the inner wall of the electrical cavity 15 is surrounded by guides. The water groove 3; the size specification of the water guiding groove 3 is 3mm-10mm.

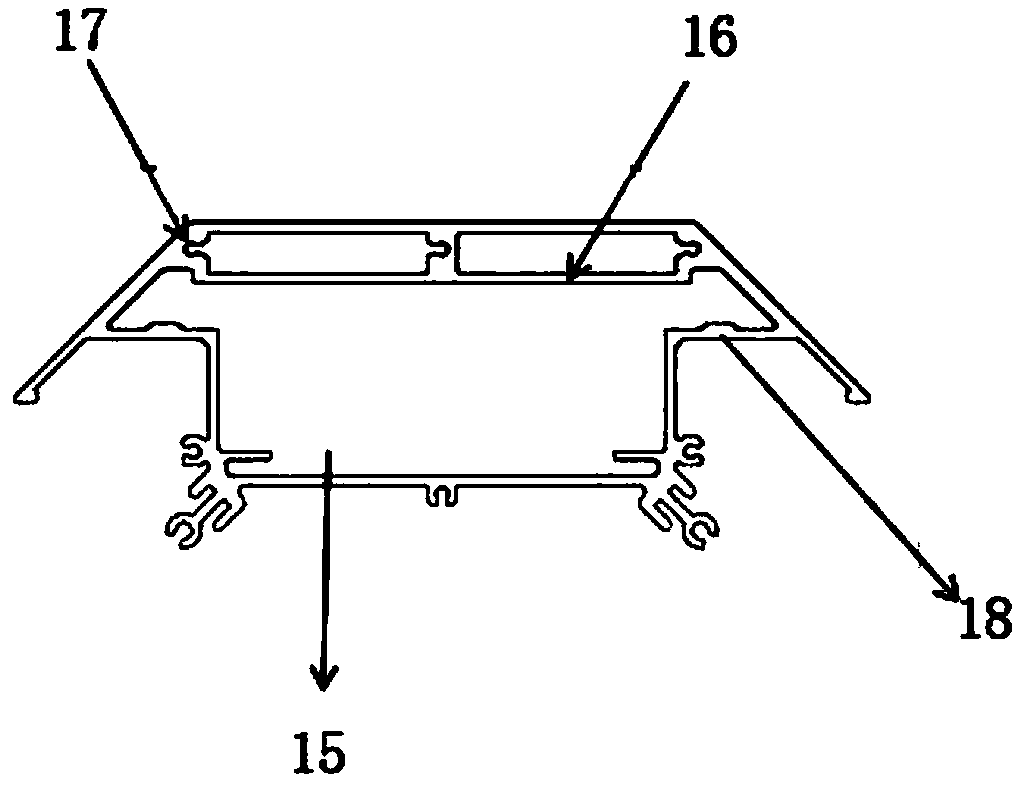

[0067] Please refer to image 3 , image 3 is a cross-sectional s...

Embodiment 2

[0082] Please refer to Figure 10 , Figure 10 It is a schematic diagram that the interface module 2 is arranged in the middle of the box main body 11 . This embodiment is basically the same as Embodiment 1, the difference is that the interface module 2 in this embodiment is arranged in the middle of the box main body 11 . When the interface module 2 is arranged in the middle of the box body 11, grooves 3 are provided on both sides of the box body 11; waterproof joints 4 are installed in the grooves 3, and the waterproof joints 4 adopt a distribution form of four in and four out; The waterproof joint 4 can also be stretched to the lower sealing plate 12 of the box main body 11 to connect the power line and the communication line.

[0083] Please refer to Figure 11 and Figure 12 , Figure 11 It is a schematic diagram of wiring of multiple box main bodies 11 . Figure 12 It is a schematic diagram of the top view direction of Fig. 11. When there are multiple box main bod...

Embodiment 3

[0085] Please refer to Figure 13 , Figure 13 It is a design schematic diagram of the interface module 2 of Embodiment 3. This embodiment is basically the same as Embodiment 1, except that the interface module 2 of this embodiment is provided with the bottom end of the box body 11, that is, a cavity is dug at the lower end of the box body 11 to form an electrical wiring cavity, and combined with The sealing plate 12 hides the wires, so that the bottom of the electrical wiring cavity forms a cavity with accommodating space, which facilitates the routing and placement of the box body 11 to hide redundant wires, and improves the safety and aesthetics of the box body 11; Water resistance and ease of operation.

[0086]The expandable pluggable modular box of the present invention can prevent accumulated water and dissipate heat at the same time, provide an installation plane for electrical components, reduce load, facilitate the installation of different functional components, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com