Floor brush and dust collector

A rolling brush and cover technology, which is applied to vacuum cleaners, cleaning equipment, household appliances, etc., can solve the problems of rolling brush motor danger, etc., and achieve the effect of reasonable layout and simple and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

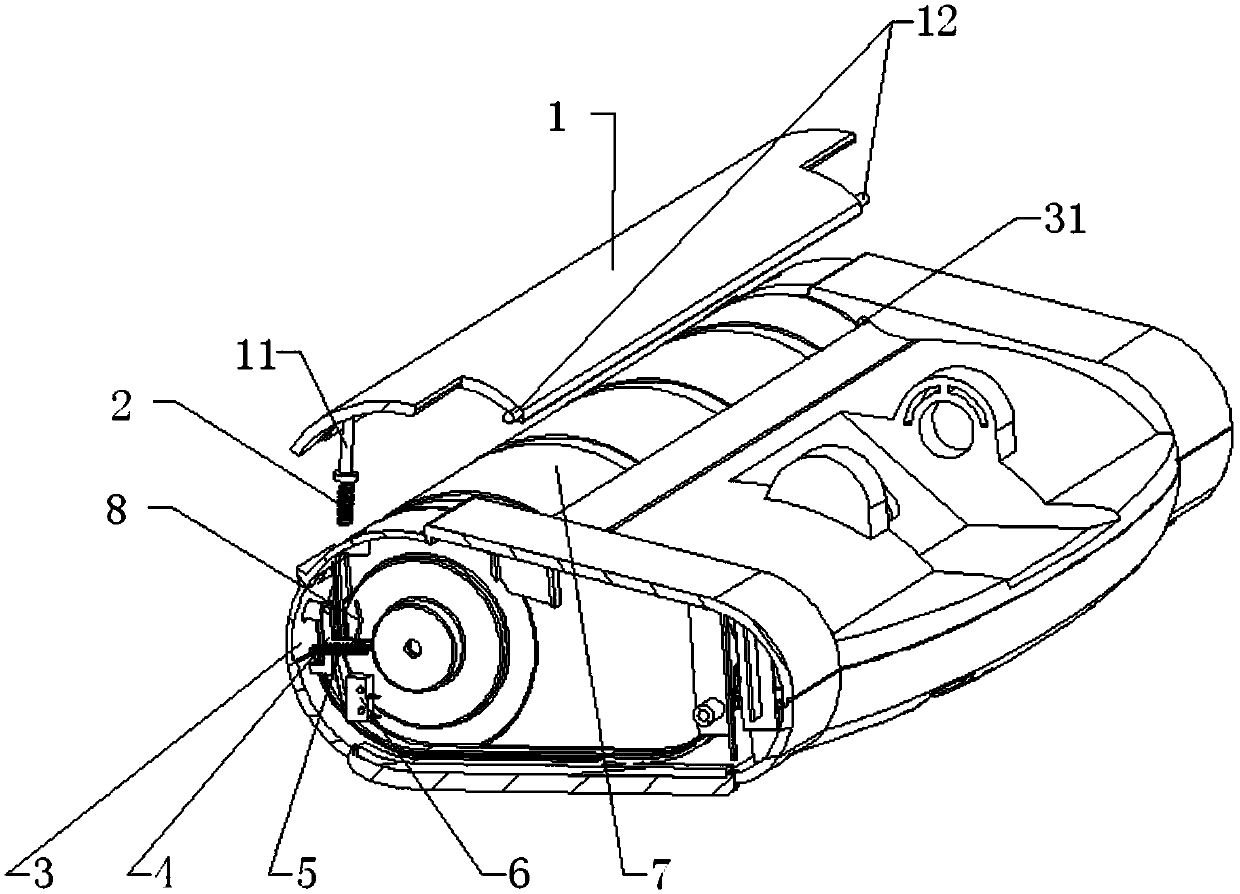

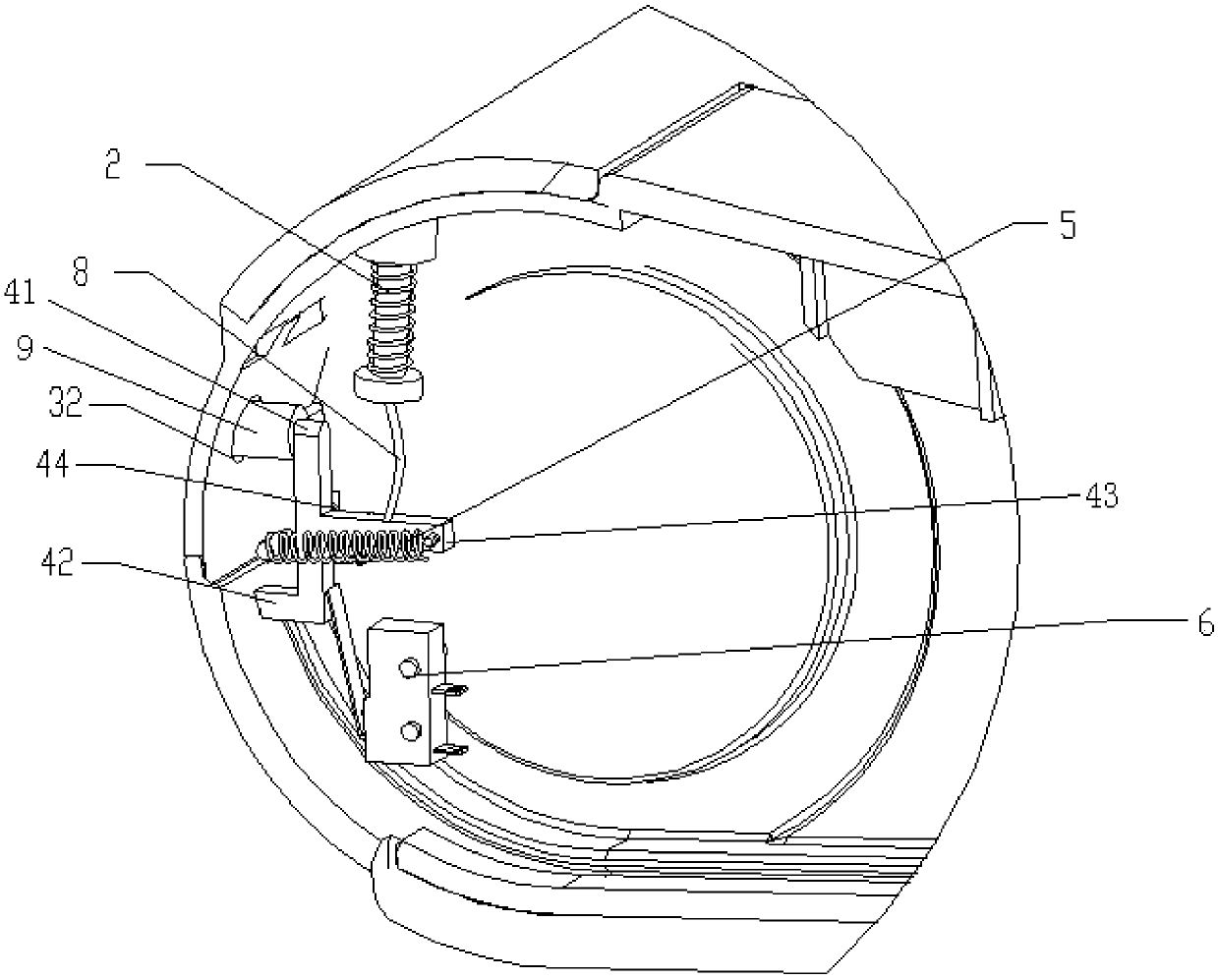

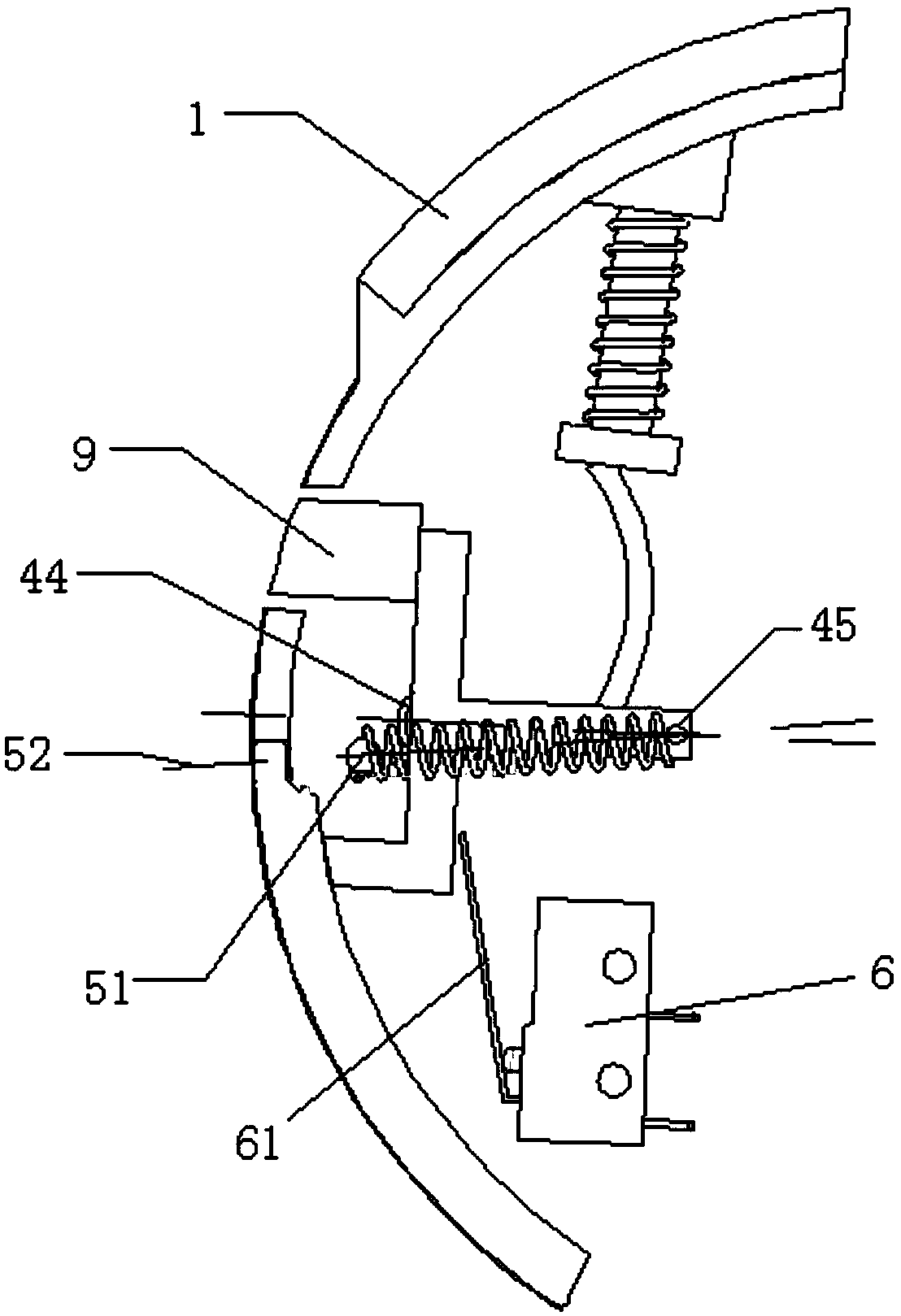

[0058] This embodiment provides a floor brush, including a housing, a rolling brush 7, a normally closed switch 6, a lever mechanism, and a reset structure.

[0059] Such as figure 1 As shown, the housing includes a base 3 and a cover 1. In this embodiment, the cover 1 is an upper cover, and the cover 1 is arranged on the base 3 in an openable and closable manner. The cover 1 Under the action of the external force inside the cover 1, it can be moved from the closed position to the open position. One end of the cover 1 is installed in the pin hole 31 of the base 3 through the pin 12, so that this end of the cover 1 Hinged to the base 3, the other end of the cover 1 is connected to the base 3 through a bias connection structure, and the cover 1 overcomes the bias force of the bias connection structure from closing when subjected to an external force from the inside. position moves to the open position; when the cover 1 loses the external force, the bias connection structure dri...

Embodiment 2

[0070] This embodiment provides a vacuum cleaner, including the ground brush provided in the above embodiments. The vacuum cleaner is safe and reliable when cleaning the entanglements wound on the roller brush 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com