Screening device of sorting machine

A screening device and sorting machine technology, applied in sorting and other directions, can solve the problems of product mixing, large manpower occupation, low efficiency, etc., and achieve the effects of easy maintenance, low cost, and guaranteed quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below according to the drawings and embodiments.

[0014] refer to figure 1 , 2 , the present invention, the screening device of sorter, comprises:

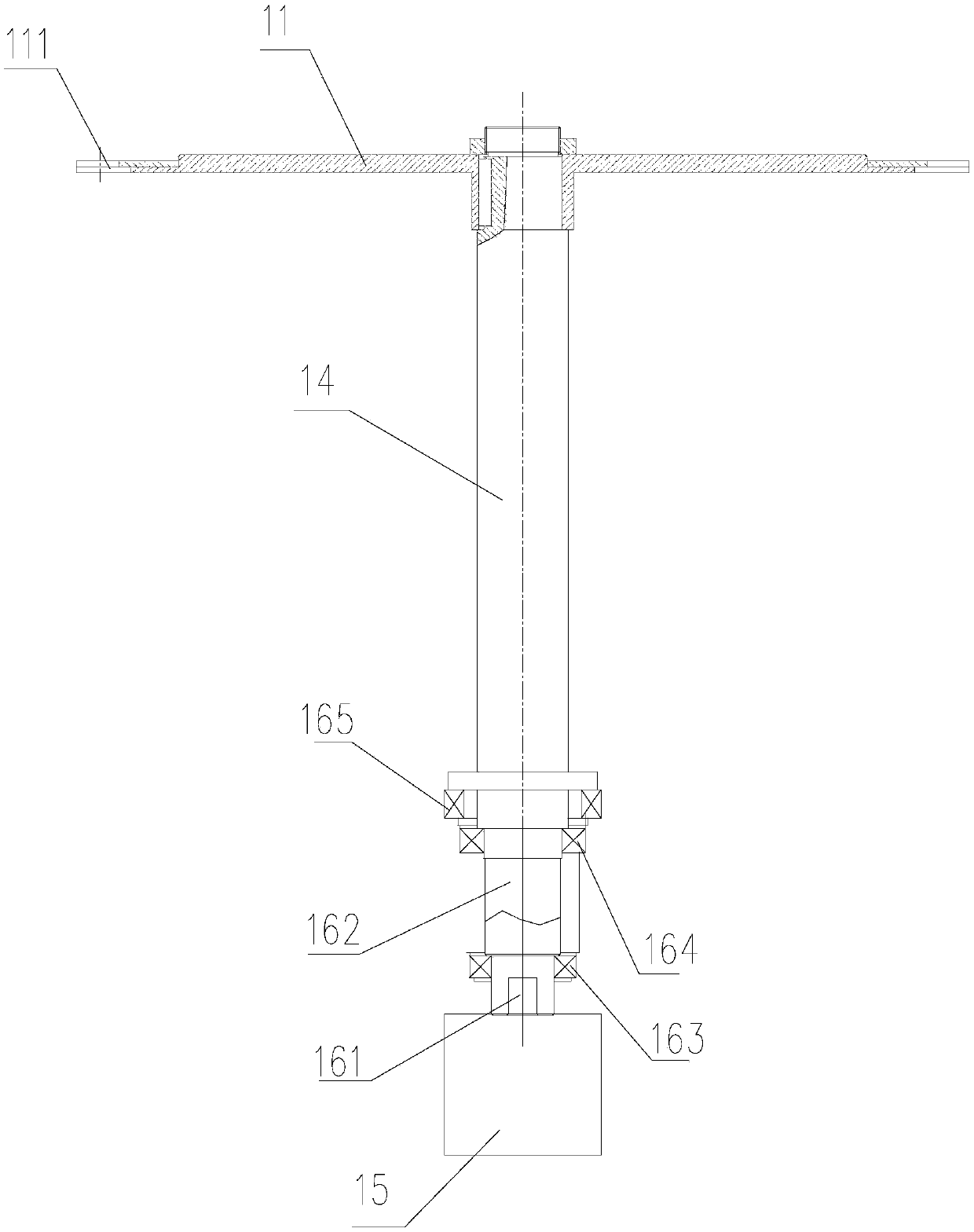

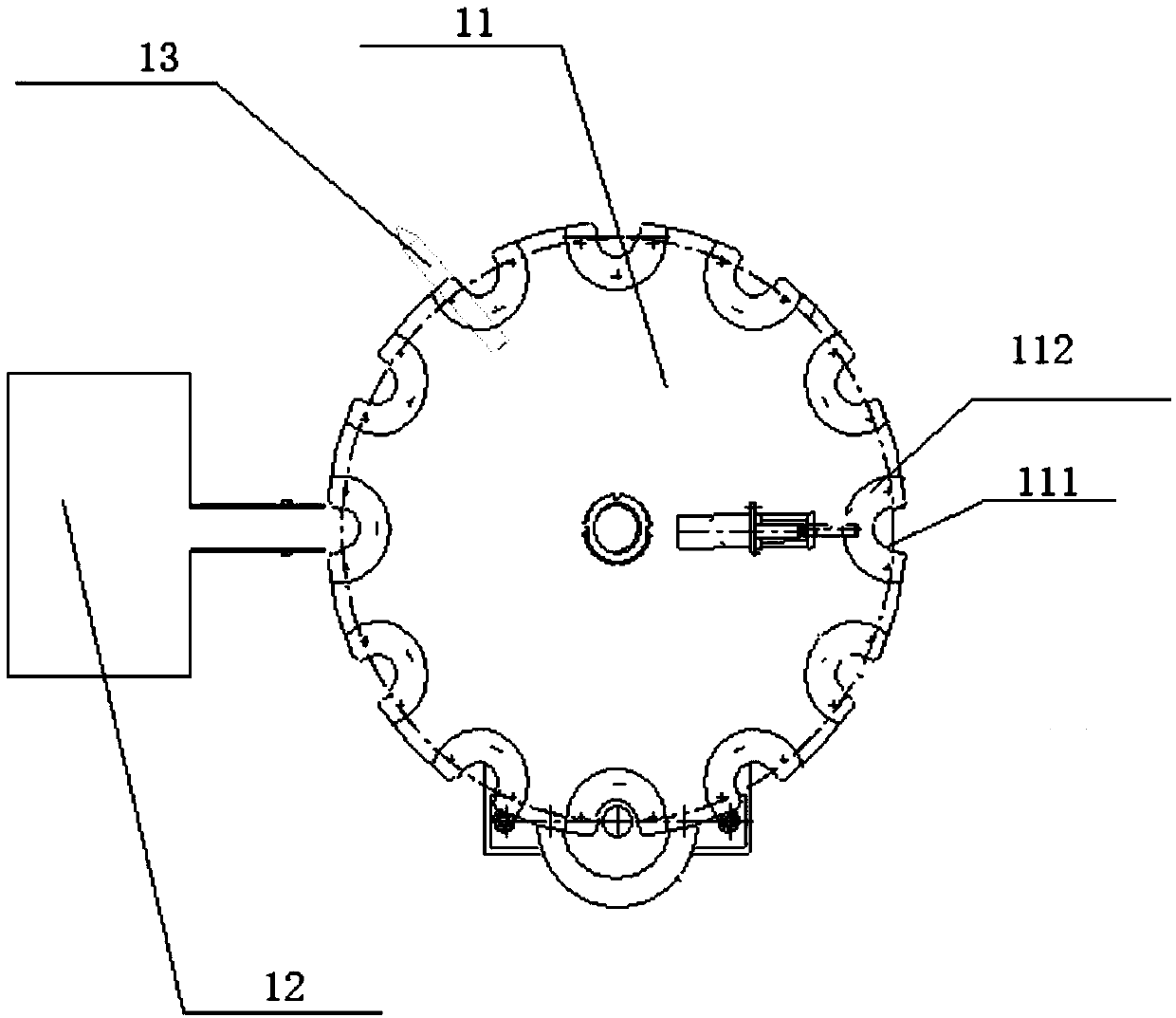

[0015] Dial 11, feeder 12, blanking lever 13, main shaft 14, rotating mechanism, screening motor 15, above-mentioned main shaft 14 is vertically arranged and the top is fixed on the center of above-mentioned dial 11 that horizontally arranges, and the top of above-mentioned rotating mechanism Assemble the bottom end of the above-mentioned main shaft 14, the bottom is assembled on the above-mentioned screening motor 15, the above-mentioned dial 11 is provided with a plurality of material openings 111 for placing fasteners along the periphery, the above-mentioned feeder 12 and the above-mentioned unloading bar 13 position All are fixed and aligned with the above-mentioned material opening 111 , and the above-mentioned unloading bar 13 is located downstream of the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com