Nut machining process

A processing technology and nut technology, which is applied in the field of nut processing, can solve the problems of random falling, waste not being recycled in time, and random buckles, etc., and achieve the effects of improving product quality, improving stability and stable processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The processing technology of the nut is further described with reference to the accompanying drawings.

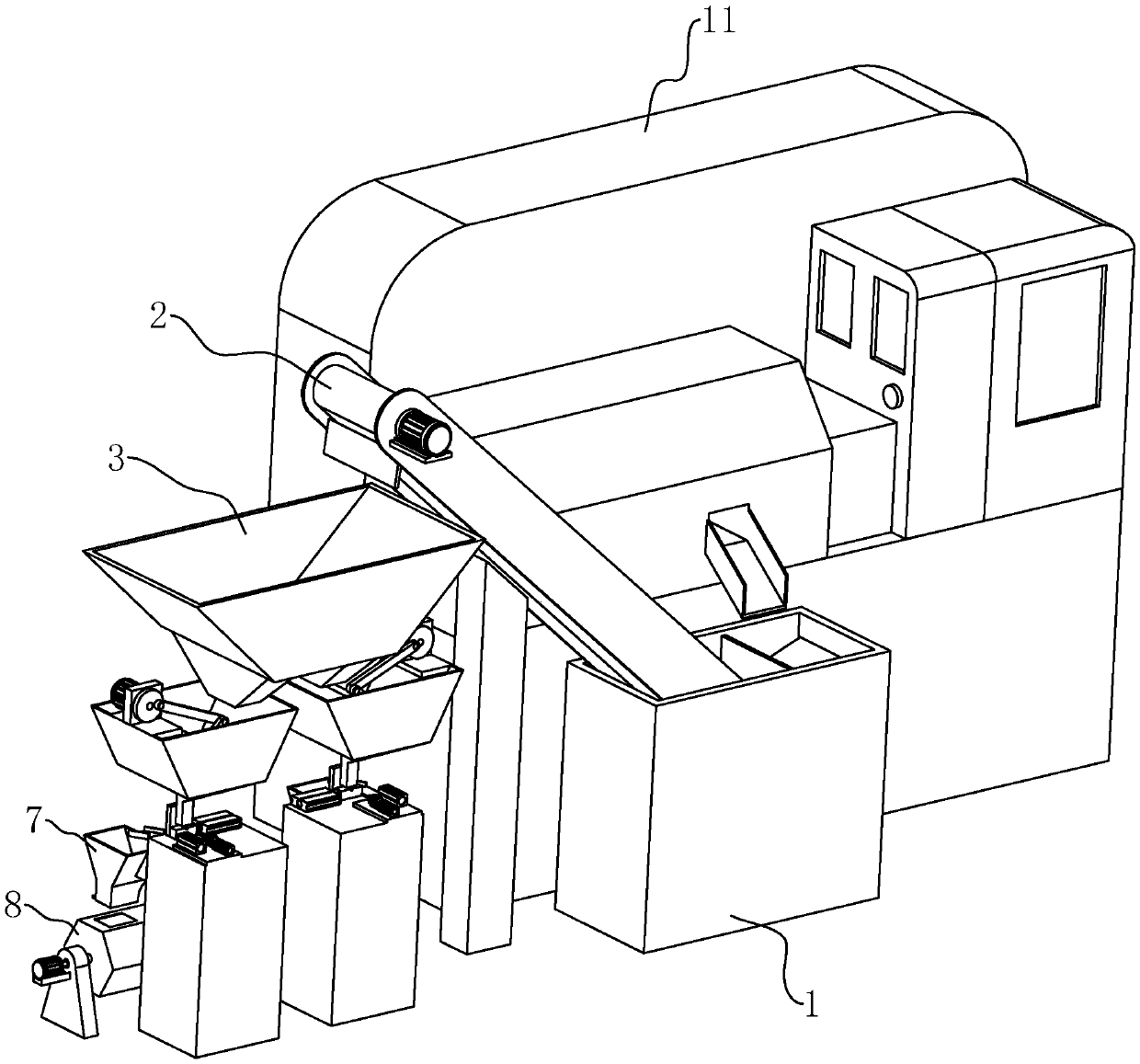

[0039] The processing technology of above-mentioned a kind of nut, as figure 1 shown, including the following steps:

[0040] S1. Pretreatment: Spheroidizing and annealing the blank, heating the pre-blank to 700~750°C and keeping it warm for 3~4 hours, and then performing cooling treatment, and the temperature is controlled between 650~700°C and kept for 4~6 hours. Take out of the oven and air cool to room temperature.

[0041] S2. Forming processing: put the pre-blank after the pretreatment in S1 into the cold heading machine 11 for processing and forming, and obtain a nut body with full and consistent corners and a through hole punched in the center.

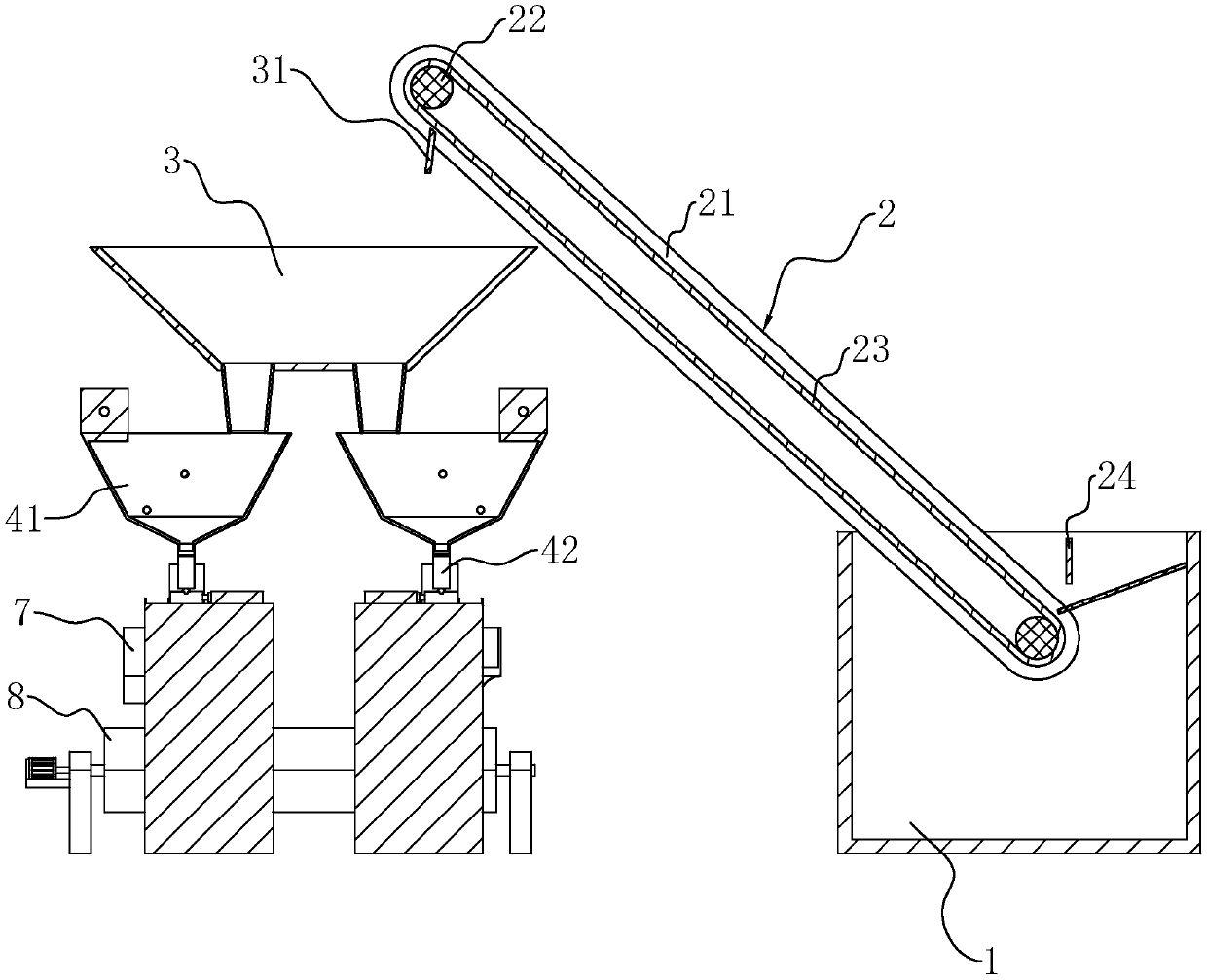

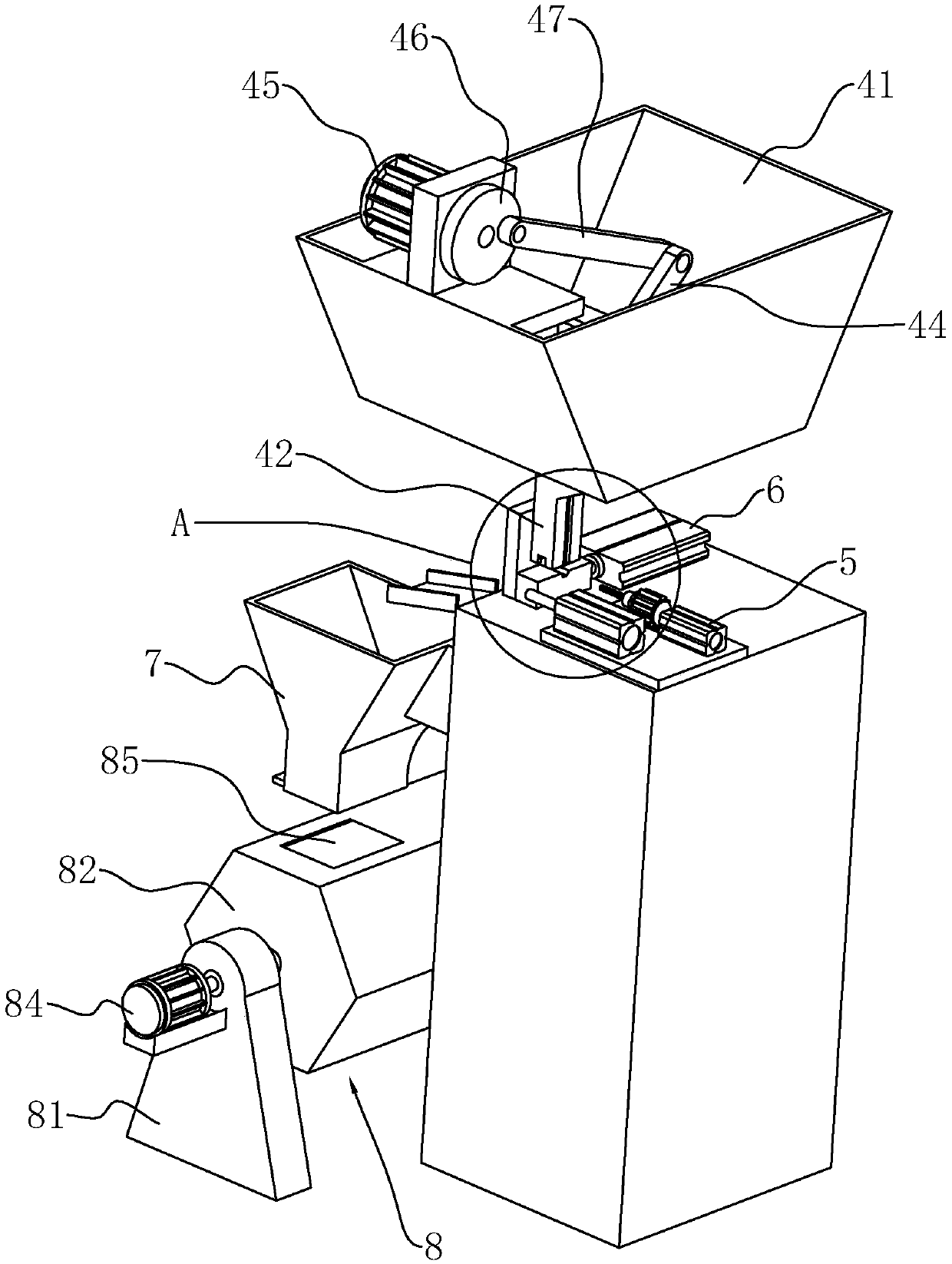

[0042] S3, deoiling treatment: a deoiling pool 1 is provided at the outlet of the cold heading machine 11, combined with figure 2 As shown, in the deoiling tank 1, there is a conveying device 2 that is inclined u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com