Numerical control machine tool cutter length compensation system and method

A tool length compensation and CNC machine tool technology, which is applied in the direction of manufacturing tools, automatic control devices, metal processing machinery parts, etc., can solve the problems of tool wear, tool instrument can not be measured, etc., to solve incompatibility, ensure processing quality, improve compatibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

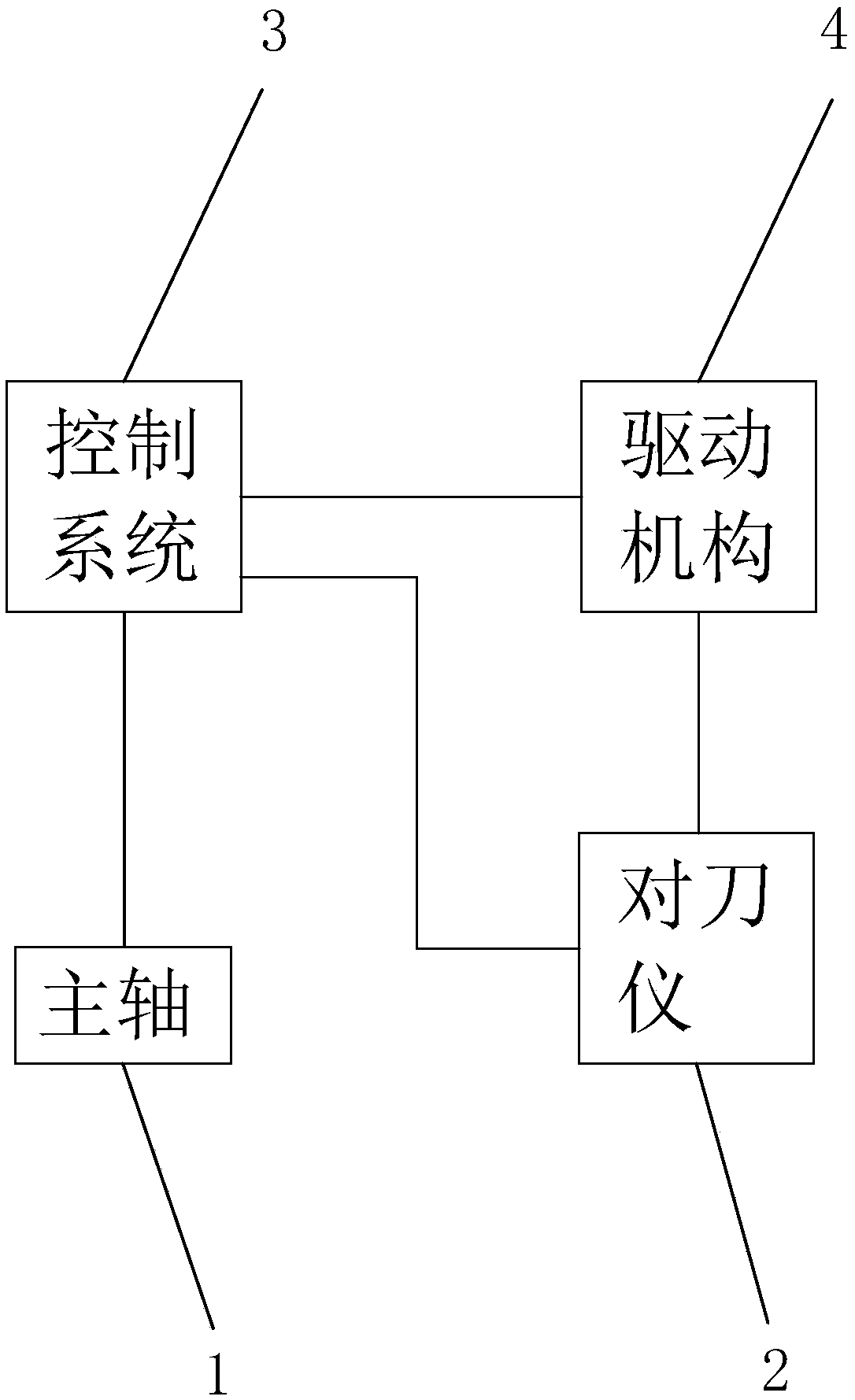

[0030] refer to figure 1 , a kind of CNC machine tool length compensation system of the present invention comprises:

[0031] Main shaft 1 is used to install the tool;

[0032] The tool setting instrument 2 is used to provide a measurement signal when it touches the tool;

[0033] The control system 3 stores the length data and radius data of the tool, and measures and stores the coordinate value when the tool is in contact with the tool setting instrument 2;

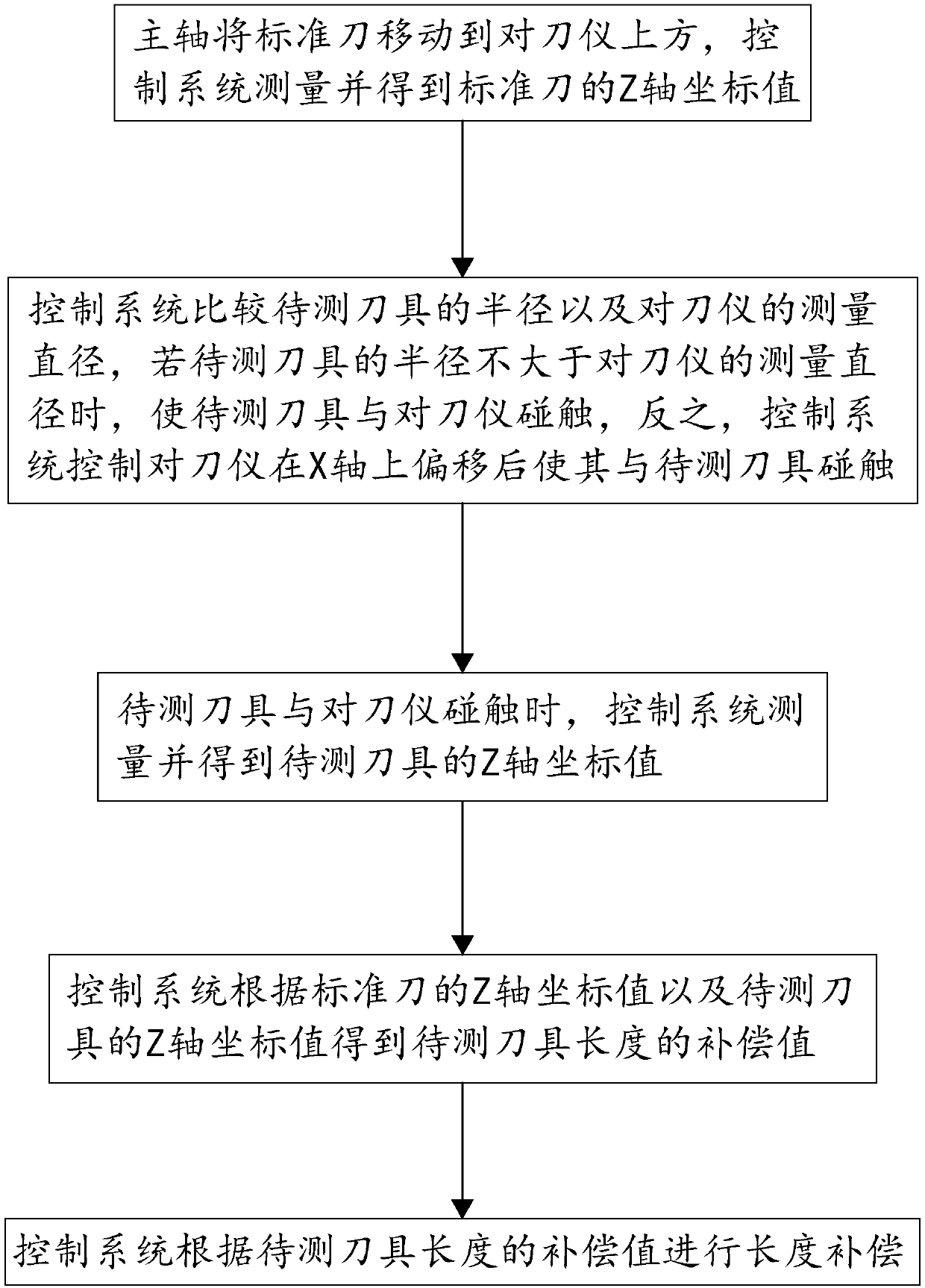

[0034] The tool setting instrument 2 provides a measurement signal to the control system 3 when it touches the tool on the spindle 1, and the control system 3 measures and stores the coordinate values of the tool. The coordinate value calculates the compensation value, the control system 3 moves the spindle 1 and the tool on the spindle 1 according to the compensation value to process the workpiece; After the tool setting instrument 2 is offset, the tool to be tested is brought into contact with the tool setting in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap