Cutting equipment for rubber product production

A rubber product and cutting technology, which is applied in metal processing and other directions, can solve the problems of the limited flexibility of adjustment, the multi-dimensional movement of the cutter, and the restriction of the processing efficiency of rubber products, etc., to achieve the effect of increased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

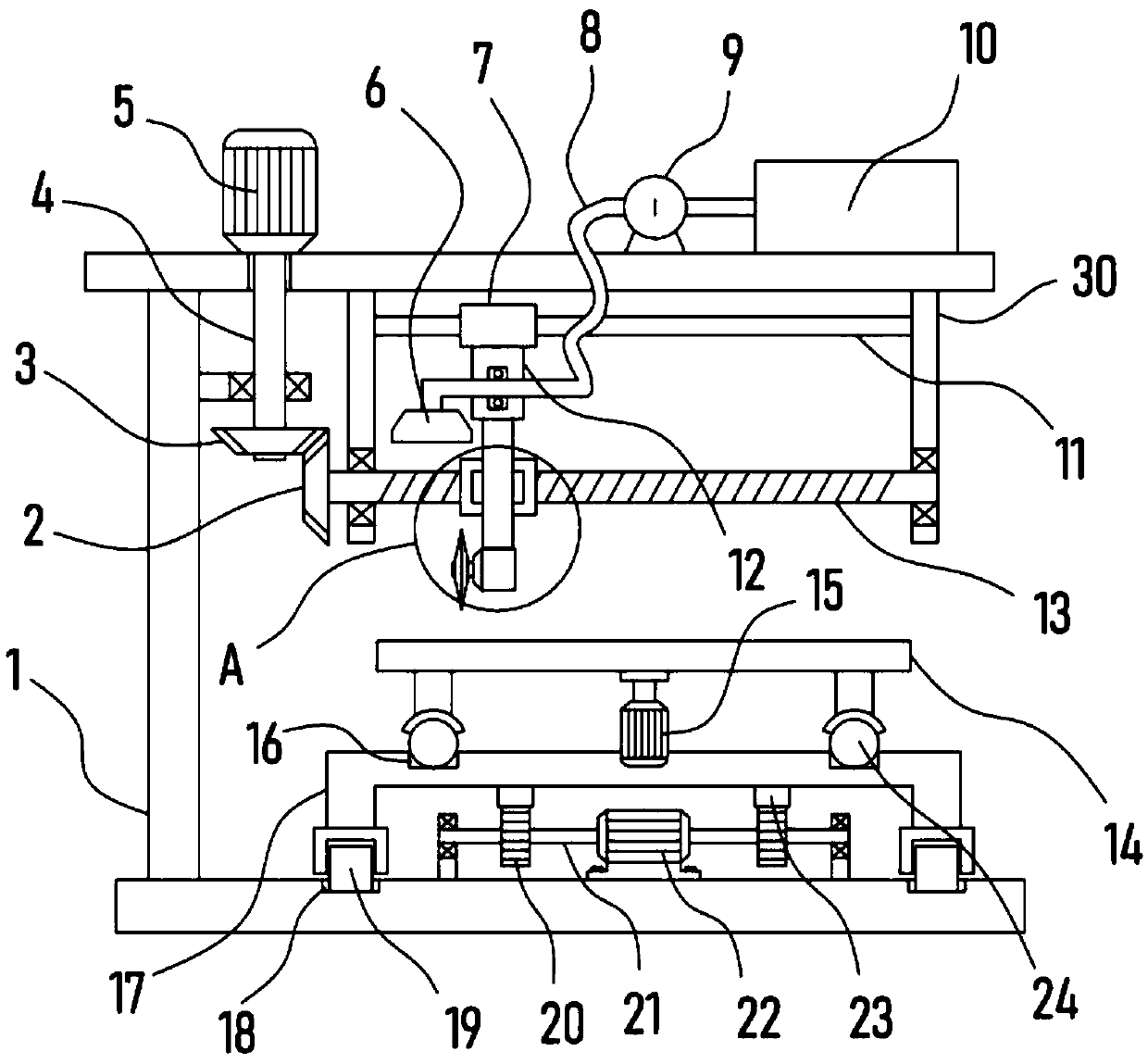

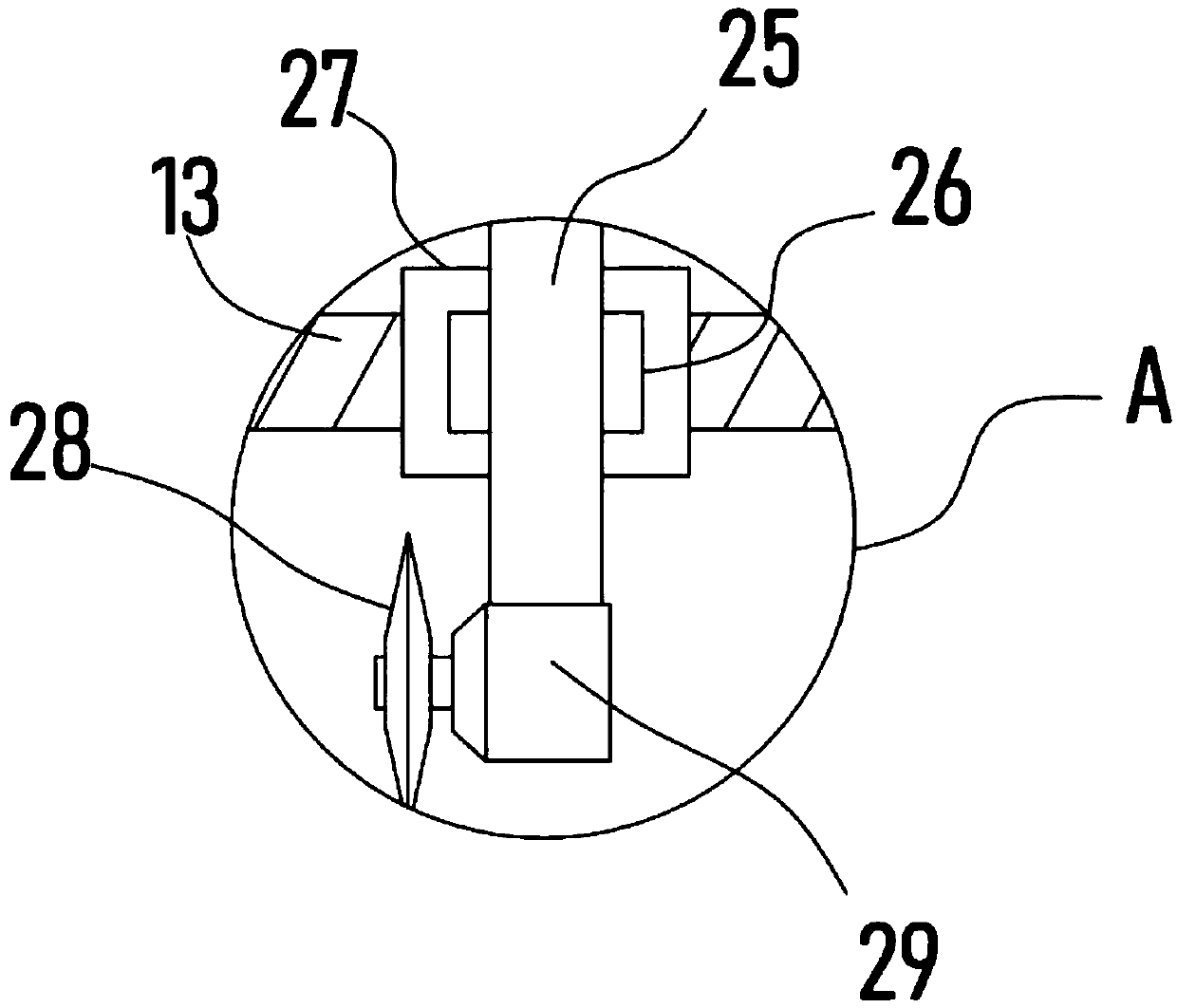

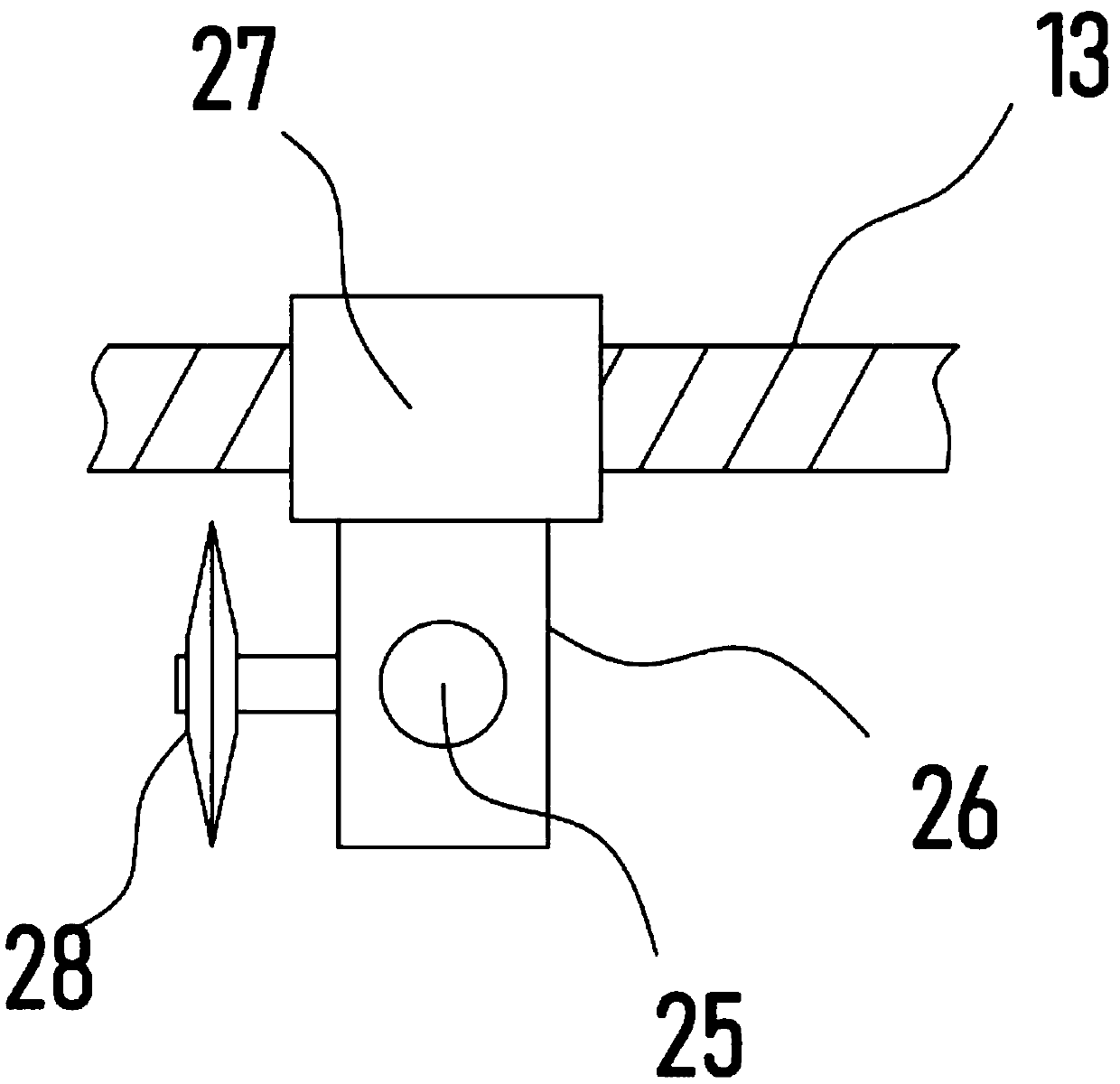

[0024] see Figure 1-6 , a kind of cutting equipment for the production of rubber products, comprising a support frame body 1, a hanger 30 is suspended and fixed on the top of the support frame body 1, a longitudinal translation frame 17 is arranged in the support frame body 1, and a vertical translation frame 17 is fixed on the support frame body 1 A stepper motor 15, the output shaft of the stepper motor 15 is fixed with a horizontally arranged console 14.

[0025] When in use, the rubber product is placed on the operating table 14, and the operating table 14 can be driven to rotate by starting the stepping motor 15. The rotation of the operating table 14 realizes the circumferential rotation of the operating table 14, so that the angle of the rubber product is adjusted, which is convenient for follow-up of cropping. In order to improve the stability of the angle adjustment of rubber products driven by the longitudinal translation frame 17, the upper surface of the longitud...

Embodiment 2

[0031] On the basis of Embodiment 1, the bottom of the support frame body 1 is horizontally and longitudinally provided with two guide grooves 18 arranged in parallel, the extension direction of the guide grooves 18 is perpendicular to the extension direction of the screw rod 13, and the bottom of the longitudinal translation frame 17 rotates The formula is provided with guide rollers 19 rolling and embedded in the guide groove 18, and the support frame body 1 is provided with a longitudinal drive structure connected with the longitudinal translation frame 17 in transmission.

[0032] In order to realize the adjustment of the longitudinal movement of rubber products on the horizontal plane, the longitudinal translation frame 17 is driven and moved by the longitudinal driving structure provided. The longitudinal driving structure includes a biaxial motor 22 fixed at the bottom of the support frame body 1. The two output shafts are all coaxially fixed with a drive shaft 21, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com